|

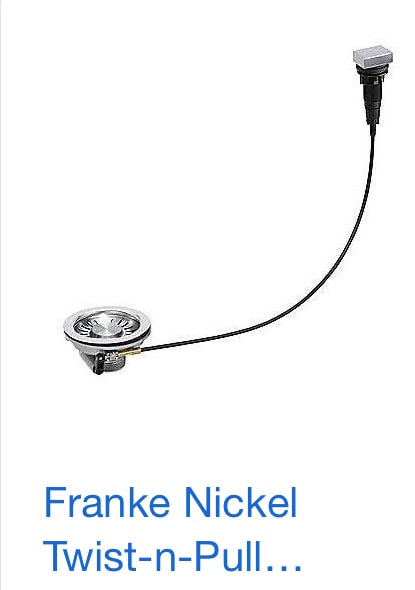

In this post Pete the Plumber wants to address a topic which, on the surface, appears so straight forward; but, which under the surface can present you with much future agony. This subject is Kitchen Sink Basket Strainers. Contrary to past posts where I excused plumbers from the class, this time around PtP has something to share with even plumbers who might not yet have (as the song goes): “…learned your lessons well.” As we all know one can purchase a basket strainer from the ‘cheap’ to the: “sucks in your breath.” Between flagship brands to those unfamiliar ones with import-car-sounding names, it’s a head spinning number of choices. Of late the extra deep designs with large, deep strainers have met with some popularity. There’s three basic methods employed to secure three basic basket strainer types to the sink, and depending upon the material of which your sink is made, one design type will be more suitable than the other type possibilities. The old dictum we all know: You Get What You Pay For applies to this situation, in spades. Aside the type differences, materials used to manufacture the product are other distinguishing factors to consider. If you are uninformed on this subject you can inflict upon yourself or customer much headache pain and degradation ($$$$) to cabinets. Yours truly remembers all too well the numerous occasions where he had to employ Sawzall and grinder to extricate a failed piece of junk basket strainer which was leaking and corroded-in-place, where the possible need to replace the sink itself was a succinct possibility. Then, at a Braer Fox labor rate (dollar a minute) to rectify the predicament, where was the economy in purchasing the cheap versus the more expensive but quality made product? This is the focal point of …”learned your lessons well.” If you are the unfortunate plumber who is faced with this headache, or a homeowner faced with paying a plumber to rectify this situation, it will be a lesson you’ll never forget. Pete the Plumber prefers quality, enameled cast iron sinks, whether single or double bowl, drop-in (self-rimming) or under-mount. The drain holes in cast iron sinks have a defined radius. There is no such radius with stainless steel sinks. There are basket strainers which have huge advantages for each of these applications. We can find varying quality with each type sold. As PtP mentioned in an upstream blog titled: Brass Is Best, dealing with toilet hardware and tubular brass trim, the same holds true for this subject. With just a little effort at comparisons you will note that the price of basket strainers (BS’s) is directly in relation to what they are made from. A solid brass basket (regardless of trim electroplating) with solid brass ring-mounting nut and solid brass tailpiece slip-nut can be up to seven times the price of a cheap stainless steel basket with Die Cast nuts or a plastic BS with plastic fastening hardware. Pay very close attention to the word: die cast wherever you run across it. (And hopefully become able to recognize it). Another name for it is misery. Die cast has no MORAL business in the plumbing realm. Wherever you find it, you eventually find failure and agony. It is a false economy, period. As for plastic versions in this application (even some so-called “designer” ones), maybe in my duck blind, but not for friends or business. Choices Number One The author will now discuss how the three most popular types of baskets mount to the sink. The first and oldest design is the cast brass basket with external male threads on its side which is fastened to the sink with a large, threaded, female ring-nut, sealing gasket and friction gasket. (Photos 1 & 2) Number Two The second most popular basket type employs a “nesting” bowl. (Photos 3 & 4) This nesting bowl is slid up from under the sink and secured to the in-sink basket’s 1½-in. running thread discharge, with a “lock/mounting” nut. This type usually has a basket formed of stainless steel and a nesting bowl (outside one) of electroplated mild-steel. (Photos 4 & 5) It is possible to find this design with a nesting bowl also of stainless steel (Photo 6) but, a chore to find one with basket and bowl both of stainless and the lock/mounting and slip-nut of solid brass. Given the choice the author would recommend the stainless basket/bowl with separate purchase (if necessary) of solid brass lock/mounting and slip-nut.  #7: Die-cast lock/Mounting nut #7: Die-cast lock/Mounting nut Though this Number Two type is easier to install than the Number One Type (solid brass basket with exterior male threads and large ring-nut first mentioned), but be cautious. Don’t be trying to do this in a hurry. Unless real care is used in the installation, a leak from under the in-sink lip of the basket will collect inside the lower nesting bowl, and if it’s a plated mild steel one will rust/corrode in a relatively short time. If your model also has die-cast lock/mounting and tailpiece slip-nut you may need a lot of patience to see you through a replacement. Such is the reason you find the models with both stainless basket and nesting bowl. If there is a leak from under the in-sink basket lip, the water will not corrode the SS nesting bowl. However, if you have a die-cast lock/mounting nut (Photo 7 ) not a solid brass one, in spite of stainless nesting bowl, you can still be in deep doo-doo for future corrosion leaks and when attempting removal. (See Installing And Repairing Plumbing Fixtures to learn how to get rid of this nut.) Take a look again at the BS in Photo 6. This is a stainless basket and bowl. But look at what the lock/mounting nut and supplied slip-nut are made of: Die-cast. Unless you replace these die-cast nuts for solid brass ones you could be shooting yourself in the foot: paid extra for the stainless bowl but still got junk nuts and future leaks. Take a good look at the slip-nuts in Photos 8 & 9. Aside the fact that you can see they are made from solid, un-plated brass, notice they have wrench flats around their circumference. These are wide and oval shaped. Now look at the slip-nuts (Photos 10 & 11).  #12: Another die-cast slip nut shape (lower) #12: Another die-cast slip nut shape (lower) Aside from being electroplated, they have rectangular wrench flats; some, separate by short scallops like these. Photo 12 shows another die-cast wrench shape with rectangular wrench flats, without scallops. These shapes should set off warning bells! Ninety-nine percent (99%) of the nuts that are of these shapes, regardless of finish, are your enemy.  #13: Die-cast with brass appearing electroplated #13: Die-cast with brass appearing electroplated Notice the die-cast nut in Photo 13 has a brass resembling electroplating. Some hardware stores will sell solid brass slip nuts but rarely, also, the standard 1½-in. running pipe thread lock/mounting nut. If this is your case, go to a large, professional, plumbing supply and show these pictures to the Will-Call clerk and tell that person Pete the Plumber said, that because they (the plumbing supply) were the only source (you’re only bothering them for this reason), that if you paid cash (and did not request the bother of a receipt), they would probably agree to sell it or them, to you. Number Three Type (on offer) This Number Three type (Photos 14 & 15) is less common but has been around for a long time and in part borrows its sink attachment method from one of the popular garbage (food waste) disposer mounting systems. Unfortunately this design, other than the stainless steel basket, is comprised from plated steel parts and of course is offered with die-cast tailpiece slip-nut, sure to corrode fairly quickly without the utmost care. Also unfortunate: if this type were to be offered in all stainless (including screws), it would be the simplest and best one for the new learner to install, requiring only a good quality pair of blunt nose pliers.* In this Number Three type, the sides of the stainless steel basket have two or more protruding lugs. Think of them as little lumps. Once the basket is set in the sink hole, a circular, u-shaped ring, inverted, is slid up from underneath to the sink bottom. Usually residual plumber’s putty squished out from underneath the basket lip oozes out also under the sink hole. This is handy at sticking the u-ring in place long enough to align the lugs of the basket with the corresponding notches in the screw plate. Then, the plate is lifted and rotated above the lugs on the basket sides. Now it’s merely screwing the three mounting screws (alternately) in the plate until the whole apparatus is very snugly in place. *If a manufacturer were to offer this Number Three type of BS, with a quality, cast brass basket (extra deep), with two, lug height positions, in conjunction with an ALL stainless screw plate; and, using SS Allen screws (studs) shipped with a quality fabric reinforced neoprene sealing washer, plumbers (of a quality trade) would so quickly adopt this fool-proof design that their product would corner that high-end market within a decade, or less. Which One Where ‘Tis time to talk radiuses. As the author briefly noted upstream, enameled cast iron sinks (and composite ones also) will have a radius around the drain hole. Depending upon manufacturer, it is possible to find this radius carried to a slightly projecting ring on the bottom, underside of the bowl. The thicker this dimension is (from finish, flat surface around the hole at the inside bottom of the bowl) to the underside of the sinks raised (ring), the greater the length the threaded exterior of the first mentioned Number One type (Photo 16) basket must be. We need sufficient protruding threads to host the two flat gaskets (one rubber, one fiber), Photo 1, and the large threaded ring nut. As a rule of thumb, the less expensive the basket strainer, the shorter this dimension is. It is quite common to find yourself with a BS that is too “short” to install in usually higher quality, enameled cast iron sinks, like Kohler’s line. The author used to ask Ragnar at The Sink Factory (http://sinkfactory.com/) to hunt me down a quality, longer one whenever I ran into this predicament. However, for the vast majority of cases, my favorites, McGuire and Kohler, had me covered. (SS) Stainless Steel Sinks Stainless steel sinks pose a bit of a challenge to install Number One type BS’s, for two reasons. The first is because there is no radius on a SS sink drain hole. What you find here is a slightly tapered flat, running around the hole in the sink bottom. This flat tends to be wider than the lip on the basket and when the Number One type’s threaded ring-nut is threaded all the way up, the BS still has a tendency to creep because it is not being held in place by the shape of the drain hole. This is not to say that you cannot/should not attempt to install a Number One type in a stainless steel sink. The author installed quality (solid brass) BS’s in a café’s NSF sinks back in the 1980’s and they’re still on the job.* Besides the SS sink holes flatness, we see that when the BS ring-nut is threaded all the way up, that if it were a perfect world, due the sinks thin thickness, we would surely appreciate a few more threads. Also, when the installer ‘goes’ for that final snug, the rubber sealing washer tends to squish out of place and you’ve failed. Is it your fault? Yes and no. It’s not the same case for a many year vet and a newbie. But there is a way which almost guarantees success. * To achieve such decades longevity of leak free service demands fabric reinforced neoprene sealing washer, good quality fiber friction washer, solid brass ring-mounting nut and conscientious workmanship, mentioned below. It’s the Threads In an upstream In The Pipe, titled Brass Is Best, the author brought up the tag: Old World Quality. That applies to the situation you maybe find yourself in presently. Many years back that flat rubber sealing washer that is (now) too soft for the duty required of it, used to be made with layers of cloth (threads) reinforcement (or backing) which retarded creep wonderfully; and, you could ‘go’ that extra, success attaining ‘bite’ without squishing out the washer. Today we find that extent (fabric reinforcement) of ‘thoughtfulness’ and thoroughness of manufacturer as rare as living dinosaurs. The fabric layered, neoprene, gasket material is alive and well, on the web. A cardboard pattern and a sharp X-ACTO will solve your dilemma, if you can find a supplier offering the material in a ‘small enough’ purchase amount to merit the effort. (Thickness of the gasket material is also of concern. On SS sinks, with Number One type baskets, it is best to have a ¼-inch thick fabric reinforced gasket. (Merely stacking two, thinner, un-reinforced gaskets most often spells failure.) Benefit of the Number Two type Basket/Nesting Bowl BS Because Number Two type BS’s secure themselves to the sink with MUCH less rotational force than Number One types, the flat, un-reinforced rubber sealing gasket has less tendency to creep (squish out) to failure. (On Number One types, that cardboard or POLY flat washer installed over the rubber one is very important. The theory behind this cardboard/POLY washer is that it lets the large ring-nut slide (relieves friction) and keeps the compression force more of straight-up instead of twisting (rotation) which creates squishing out. If you leave it off or don’t have one, you’re dead-in-the-water. Thus it has always fallen under the description: friction washer. If yours is fiber/paper and in poor condition, you can purchase a new one or make one from a ½-gallon poly milk container.) With Number Two types (Photo 4) this fiber/friction gasket/washer can be left off and sometimes it is not even shipped with the BS because the cheaper, un-reinforced rubber gasket usually suffices (until you move, if you’re lucky), when carefully centered and sufficiently, but not over torqued. Nit-Pick Is it the Virgo in me that causes an itch when I see, on a lip of an expensive, Number One type’s finish, a name or logo set at anywhere but 12 o‘clock? Or, sans logo, looking down onto the cross in the bottom of the basket, and not finding it almost perfectly vertical/horizontal? Two Final Thoughts If you have an aversion (due to allergy or psychosis) about reaching down to the strainer knob to drain a full sink bowl (especially a deep one) you might look at a pop-up drain. (Via internet or restaurant supply.) A restaurant/commercial version (Photo 17) has a lever or a knob which activates a linked internal stopper for dry hands operation. Of course these actuators will be located under the sink. Versions designed for residential use (Photo 18) use a cable, or lift-rod (Photo 19) actuated by a pull/lift knob mounted on top of the sink. But hey! you might find them worth the extra cost (purchase and installation) to spare you from your willies. Well, one last note. That is: what medium to use under the BS’s lip. Pete the Plumber has always advocated good quality, new, plumber’s putty. (See Installing And Repairing Plumbing Fixtures.) My Good Buddy plumber friend Larry (https://www.larryweingarten.com/) swears by Silicone Sealant. Whichever method you use, if your work is conscientious and methodical you will probably be successful. Try to make it a pleasant chore. Tell yourself that the longer no one gives a thought to the performance and longevity of this basket strainer (actually this applies to all of your work) the better plumber you were/are. This pleasure is rarely achieved with less than top quality components. Until Next Time, PtP Photos made possible by Bayley Lumber: bayleylumber.com/

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Author

Peter Hemp is a San Francisco East Bay residential plumber and plumbing author and former R & D steam vehicle plumber. His hobbies are ocean kayaking and touring the Left Coast by bicycle. Archives

September 2021

Categories |

|

|

Copyright © 2017 - 2022

All Rights Reserved

All Rights Reserved

RSS Feed

RSS Feed