|

This In the Pipe is, again, a Tool Time tale. It’s also a tale featuring a new product of the tool manufacturer mentioned in the last post (but not the first of its kind) plus some of the author’s observations on earlier versions of this tool type. This time, instead of a basin wrench (Photo 1, below) it is a tubing cutter. And again, the featured object is a re-hash of a previously marketed widget. (In the present case, last seen at Will-CALL counters when Ronald Regan was President.) One of the widgets (Photo 2A & 2B, below) had/has been a long-time successful member of their product line. And again, the author’s respect for this tool line causes him to pause, before making a thumb’s up or a thumb’s down decision on the newest offering, too soon... But, I do wanna tell you a few things about other related offerings too. The new featured widget, the Ridgid “2-in-1 Close Quarters AUTOFEED® Cutter,” (Photo 3, below left), the author used as an earlier design, in a slightly changed form, thirty-years ago when manufactured by a different firm. At the time of first spying it on the Will-Call-Counter at a plumbing supply, the author thought: “Better than sliced bread.” Well, it didn’t turn out that way. Prior to the arrival of the first incarnation of this tool, plumbers had only limited means to cut copper tube ‘in-wall’ and under floors and other “hard-to-reach” locations. All of which pose dangers to the knuckles of the hand that is operating. Although, there did exist an already jiffy little soldier (just mentioned above) to employ for this task. In his books and writings the author has referred to this little warrior as a/the “knuckle-buster.” (Photo 4, below right) My tool bucket has at least two knuckle busters aboard, and I could probably find more if I dug to the bottom. The bucket does not contain a new Ridgid, (Photo 3, above left). Why? It has to do with the necessary design of the tool. (I already tried out the original progenitor and after initial use found that I rarely did again.) To accomplish, with one hand, what it takes two to do (operate) the knuckle buster, the newest offering accomplishes more with fewer one-hand movements, but takes significantly longer to do its job. The author remembers countless occasions where he’s cut and or abraded his knuckles making repairs to copper pipe in walls when using a knuckle buster (Photo 4, above right). It’s not the tool that causes the injury. It’s the operator’s limited/compromised vision and/or inattentively operated hands (including knuckles). Sharp splinters, wire lath, old wood lath nails, gashes in heads of hand driven, set nails, and sheet metal edges of carpenters’ specialty ties are some of the adversaries awaiting the repair/remodel plumber when cutting pipe in existing structure. And that is what I initially hoped this “long handled” design would spare me. What it advanced on one front it fell short on another. I will tell you about it following. Silver Knight? One look at the new Ridgid close quarters tool and I think most people would see that at its heart it is a knuckle buster inside an additional, ratcheting housing. The two biggest drawbacks of this design (as experienced) are these:

Also, Photo 5 below left, AutoCut, is what has successfully challenged the original Ridgid knuckle buster, the heart of the new offering. It is not made for equal longevity but the now attitude: “use-and-toss the cheap,” entrenched by Big Box Store trade has vetted it. This ‘newer-comer’ design works surprisingly well and is six times faster cutting than the conventional knuckle buster or traditional cutter shown in Photo 6, below right. Our cheapie in Photo 5, below left has no knob to hang up on obstructions. You can use slide-jaw pliers to rotate, in-wall, when the going gets tough. It cuts quickly with automatic cam action. And, at big box stores so much cheaper than a US or Japanese made knuckle buster like Ridgid’s ‘Sherman Tank’ C-Style models mentioned and illustrated, downstream. Big Improvement It might sound a bit improbable to many of you but there has been a marvelous, SIMPLE improvement in Ridgid’s Model # 104, the basic work horse knuckle buster. Look carefully at the next two photos, Photo 8A & Photo 8B, below. Everything at first looks exactly the same. One picture is one of my old 104’s and the other is the new version. When your eyeballs land on the adjustment knob of the new version, wa la. Original is round. The newbie is oval. Might you ask why such a small difference makes such a big difference? It made a huge difference. The round knob of the original #104, at times, cannot be tightened enough with fingers alone (especially on Type L copper tube) so a small pliers is applied. If the knob were square (Pete’s recommendation to the company 30 years ago) a small Crescent wrench would have made it much easier to use. The round knob is knurled and many times, under perfect conditions, only fingers do fine; but, you will run into the need, sometime, to add a gripper tool. Now, look at the oval knob of the new #104. Just this little tweaking of shape eliminates the need for an added tool. That extra out-of-roundness gives stout thumbs tremendous advantage. With time of use, there would be measurable labor savings too. For “new entry” plumber/participants, this old man would tell you to buy the Ridgid models C34 (Photo 7, below left) and C10 cam action close quarters cutters and a Ridgid 151 Quick Acting tubing cutter (Photo 9, below right). The C34 does ½-in. and ¾-in. tube and the C10 does 1.0-in. I would recommend these to ‘first timers’ even over the simple, slow but dependable action of the familiar (Photo 6, above) time-tested design. One especially appreciated (Photos 10A & 10B, below) is a German designed small tube cutter. Its cutting wheel all but disappears into the handle and allows the operator to cut ¼-in. and ⅜-in. copper refrigerator “reefer”tubing, all the way up to and including 1½-in. Type M and Type L copper pipe. It’s a product of Germany and on my particular one the name Rothenberger lies on the twist knob. The author has no recollection as to where he procured it, but he knows that it’s the second one he’s owned. Well, stay ‘at it’ long enough and you’ll discover it’s best to have a ‘collection’ of certain tool designs, and this area of tubing cutters is a good example. (Larry Weingarten’s best collection is that of his pipe wrenches.) If you have the $$$ to fritter, PtP would have to say the new Ridgid AUTOFEED® would ‘round out’ a collection. Until Next Time…(don’t accept any wooden Nickels)… P t P

0 Comments

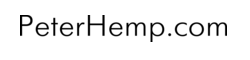

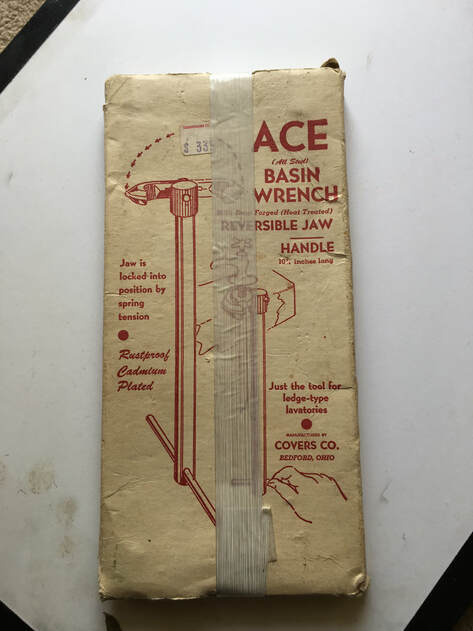

Visiting a wholesale plumbing supply recently (it was a Friday and they had free hot dogs, chips galore and salads), a tool vendor had a display table set up. (That’s how these things work: The vendor foots the grocery bill and the supply house provides the venue and the plumbers are their ‘mark’. Some tools and widgets are bought by the plumbers and the plumbers get a free lunch.) This happens invariably on Fridays, most often during the summer months. But, sometimes an impromptu event goes live at an unpredictable date. On this particular pig-out (PtP has a hella appetite), the Ridgid Tool Rep was displaying. The author has always trusted Ridgid brand tools. They’re tough stuff. I prefer their pipe wrenches over all others. This day my eye was snagged by two items, a copper tubing deburring tool and a new ‘version’ of their famous and industry best, basin wrench, model #2017 (Photo 1, below left). The author has owned the original version wrench (Photo 2, below right) for 30 years or more. It’s indestructible and it’s the best one out there. Of course my curiosity was instantly piqued. For 40 years yours truly has been installing new, and replacing existing faucets. The “re-invented” Ridgid #2017 “LED” Basin Wrench on display that day, (Photo 1, above left) had two features which differentiated itself from the original #1017 that had served yours truly, faithfully, for decades: 1) an LED light, and 2) a ⅜” socket at the handle base which hosts a “gimbaled” slide-bar handle. (PLUS: the ability to remove this handle and attach a ⅜” ratchet or breaker bar.) PtP confesses that when extra leverage was required to unthread “stubborn” valve “lock/mounting nuts” and an adjustable Crescent™ wrench was applied to the bottom of the SQUARE shaft of the original #1017 telescoping basin wrench, getting the adjustable wrench installed WITHOUT losing the purchase of the spring-loaded ‘claw’ (Photo 3, below) of the original #1017 on the valve’s (usually lavatory or kitchen sink) lock/mounting nuts, sometimes required more than one or two attempts at this task. Did my original #1017 ever fail me? I can’t remember one “specific” case. (Though PtP DOES recall several occasions where he had to grind the teeth (on one side) of a good quality reciprocating saw blade (Lennox) so he could “saw off” a faucet body (and not harm the vitreous surface of the bowl) when the lock/mounting nuts of the defunct valve were too corroded (majority cases: ‘pot metal’ see “Brass Is Best” article) to allow conventional removal of the valve. (This also extended to valves on legged tubs.) After this late opportune ‘feast’, PtP sent an ‘inquiry’ to Ridgid Tool Company asking if they would provide yours truly with a “loaner” so he could use their new offering in ‘real world’ situations. The company ignored PtP. Surprising? Not really. How many individual plumbers can get the attention of these big, major league manufacturers? (The author DID recommend them however in his best selling, original Taunton, “Plumbing A House” book.) (Home Depot, Borders, Barnes & Noble, etc.) PtP DOES, though, have a few comments to make on this new tool offering:

P.S. The cost twixt the LED #2017 and the original #1017 is a good time in a Berkeley bistro. But, if you are so endowed ($$$) the author, trusting in Ridgid Tools, would say: Go For It! Until Next Time, PtP |

Author

Peter Hemp is a San Francisco East Bay residential plumber and plumbing author and former R & D steam vehicle plumber. His hobbies are ocean kayaking and touring the Left Coast by bicycle. Archives

September 2021

Categories |

|

|

Copyright © 2017 - 2022

All Rights Reserved

All Rights Reserved

RSS Feed

RSS Feed