|

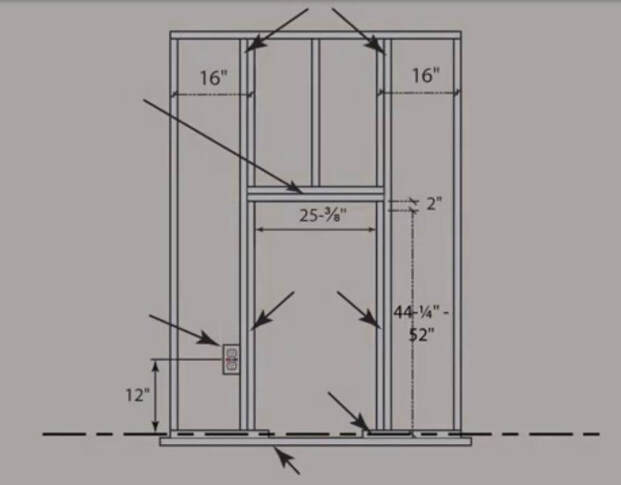

Greetings. Me wonders if in these COVID times whether the ‘shelter-in-place’ orders might be sending some of the ‘bored’ to areas of the WEB they’d not otherwise likely be going, like stumbling into ‘The Pipe’. For those of late who have been purchasing The PEX Edition of Plumbing A House (in spite of these pinched times), not to mention these most turbulent times, the author would like to thank and commend you.” On A Roll One reality very pertinent to our present circumstance is the public’s penchant to wiping out the shelves of toilet paper at their favorite outlets, once again. A good example of our ‘Freudian angst’ with an unmitigable function of human physiology? (Caveat: Pete the Plumber was recently seen with an armload himself at Wiley’s, his local market.) Toilet paper was a topic yours truly covered in some depth (Plan B) in a late post. Pete has long believed that should a mega seismic event or electrical grid collapse ever render a large metropolitan area’s infrastructure a lethal blow, loss of waste treatment facilities would be almost as debilitating as loss of drinking water availability. (You would then find the ubiquitous 5 gallon bucket as rare as the missing TP roll.) When PtP lived in Northern California’s East Bay for over 20 years, the knowledge that his drinking water traveled hundreds of miles and at one point very far away, through two, 100 plus year old, hand lain brick tunnels, crossing a major earthquake fault, was something that he would be thinking about as he dozed off to sleep. This present post is not going to revisit the TP quandary. But it is focusing on a subject that is intimately entwined with waste water treatment and TP: toilets. And, in this particular instance, a modern toilet design that is fast gaining a major niche with new and remodel architects and designers: the “inside-the-wall” (hidden reservoir) wall hung toilet known as Concealed Cistern Wall Hung (CCWH) (Photos 1, 2, 3, & 4). Because of their growing popularity the author figured this newer design was a timely subject to discuss. And/but there are a number of angles (issues) about this tank inside the wall wall-hung toilet that the author feels should be aired for the benefit of anyone who might consider incorporating one in a ‘new build’ or a remodel. In the past ‘good old days’ wall hung toilets were not that common to residential construction. Most folks encountered them in commercial office buildings, medical facilities, and maybe an occasional gas station or movie theater. These designs required ample space for their bulk. The flushometer supplied models (Photo 5) were ubiquitous. In the ‘way past’ PtP did install some in private homes. These occasions were for architects who had designed their own new homes and for clients with physical conditions that lent custom height toilet bowls an expensive imperative in a remodel. The wall hung toilets for these residential installations eschewed flushometers (for several reasons) and instead employed two-piece, ‘close coupled’ tank-to-bowl designs similar to (Photo 6). The design requirements to create a bowl which ‘hangs’ on the wall versus ‘sets’ (rests) on the floor (and which can support up to several hundred pound human bodies) mean that a lot more clay went into making the wall hung design. A lot more clay meant considerably more weight. To securely hold this heavy vitreous ware bowl to the wall requires/d a sophisticated ‘rack’ or ‘hanger’ if you will, called a carrier. The carrier in most cases is made of sturdy cast iron pieces which are bolted together and secured in position inside the wall. These carriers differ for wall type (wood stud or masonry) and brand of toilet manufacturer. The toilet manufacturer usually does not make the carrier too, but chooses one manufactured by one of several long established foundries serving the plumbing trade. Photo 7 is a carrier used with wood stud wall construction. Carriers used mainly for masonry walls are bulkier and more time consuming to install (Photo 8). PtP lobbied residential builders who wanted to employ one of these common wall hung toilets to frame the wall with a minimum 2x8 stud and preferably in 2x10. Even with 2x8’s the author recommended that several stud bays either side of the toilet be ¾ plywood with rock over. As a plumber, the author on too many occasions witnessed installations which were prone to leaking due to wall movement (flex) supporting a body during use. In one instance he recalls a leak service call to a home which had wall hung toilets (2) which were ‘back to back’ (in two separated bathrooms). A user of one toilet would feel a definite ‘bump’ and lift when a person in the other bathroom sat down on that bowl. A mini teeter-totter it was. The reason: two, heavy, elongated 2-piece tank-to-bowl wall hung toilets hung on a common, unreinforced 2x6 wall. Bulk Matters In the author's opinion, most architects and designers give the bathroom short shrift when allocating square footage in their floor plans. (Me knows it’s prejudice on my part.) Well, this issue of square footage (the less of) Pete recognizes as a big driver for the newfound embrace of the tank inside the wall wall hung toilet: Concealed Cistern Wall Hung (CCWH). Most residential bathroom space is too small. The conventional two-piece, close coupled tank-to-bowl set on floor toilet in many marginally sized bathrooms ‘hogs’ an unacceptable amount of the available space. Many times in these situations door swing can also be a difficult facet of the design to accommodate. The author believes this issue of less than optimum space is the biggest reason to consider employing a (CCWH tank inside the wall wall hung toilet (other than ease of maintaining cleanliness of the toilet and surrounding floor area). By eliminating the bulk (physical dimensions) of the tank from a toilet (whether it be wall hung or set on floor), as much as 9 to 10 inches can be “shaved” from the ‘from-wall-to-nose-of-bowl’ distance. Nine to ten inches doesn’t sound like much? When it comes to door swing and passage concerns it can make or break the feasibility of a potential or added bathroom. A New Pallet A traditional facsimile (Photo 6, above) for a two-piece close coupled wall hung toilet you might have encountered in the traditional American home of past decades is now being out competed by the CCWH (Photos 1, 2, 3 & 4 above). The space saving aspects of this design however can also be secondary to designers without square footage constraints. For them it’s an enhanced design opportunity. (‘Wall treatments rule’.) Designers can select an almost unlimited choice of color and texture for a space previously limited to merely a few different colors of vitreous. The last four photos illustrate this. (This newfound freedom of texture choice though can sometimes present a challenge to the Finish Plumber.) What A Rack The traditional wall hung (Photos 5 & 6 above) and the new on the scene CCWH don’t simply defy gravity to remain in place. The CCWH too utilizes a carrier. But due to the smaller size of bowl (and the less weight) the ‘rack’ (carriers) for the CCWH need no longer be a heavy (cast iron) ‘one-of-only-a-few-kinds’ of assembly. The carriers for the CCWH are manufactured from standardized mass produced steel square tube, usually ‘powder coated’ to resist corrosion. (Examples downstream). There are incorporated into each brand’s design of carrier, a few customized plastic brackets and tubular pieces which lend themselves perfectly suited to the economical, current expertise of the plastics industry’s mass production capabilities. Because of the many different CCWH bowl shapes found today, the toilet’s manufacturer markets the carrier also, as proprietary, and a ‘package deal’. What the foundries produced in the form of cast iron carriers for traditional wall hung toilet designs, those for CCWH are also a fraction of the weight. However, to accomplish both the support of a plastic tank (cistern) a n d hold a toilet bowl firmly on the finish wall, our new found friend is a much lighter but a physically more expansive (much taller) shape (the extra height means more leverage = strength.) So, thin wall steel material may be employed which is many times over cheaper to manufacture than the older, cast iron carrier designs. As mentioned, each CCWH carrier is proprietary to the manufacturer of the toilet. No mixing and matching. Assembling and installing the CCWH carrier (regardless of manufacturer) is vastly quicker and a joy in comparison to installing its cast iron brethren. The framing schematic (Photo 9) for one particular brand of CCWH is quite straightforward. Some others may ask for dado’s for blocking. And most framing options incorporate double studs. With accurate execution of the plan the carrier fits, and quickly. Big improvement over yesteryear’s cast iron pals. Who Me? Over the years PTP met a lot of frustration because of the way a bathroom and/or kitchen was framed. Maybe a strong structure, but much more troublesome to plumb. Upon encountering such conditions on a job the anguish was never less. As a result (the author confesses) ‘there was a chance’ PtP ‘cried in his beer’ to his fellow tradesmen. A good friend, Charles Miller (at the time Senior Editor of Fine Homebuilding Magazine) one day said to the author: “Pete, make your case. That would make a great article for the magazine.” The author did just that. The Publisher titled it: “Framing with the Plumber In Mind.” It’s a common occurrence of making living space that plumbers need to remove framing members dutifully installed by the builder that are in the wrong ‘orientation’ for the plumber to be able to install his necessary piping. The author always felt a pang of guilt when this occurred because he either had to ask the builder to alter their work or make the necessary changes, himself. Also, it was always the case of: whose job is/was it to do what reframing should/could be done to re-strengthen a structure after a plumber removed ‘just enough’ to complete his/her work? (Yours truly always offered his services when materials were provided and if it was within his skill set.) As mentioned, in the case of framing for a CCWH toilet, the carriers are proprietary to the fixture manufacturer, a reversal of the ‘good old days’. Because of this proprietary to vitreous manufacturer, the builder framing from an ‘Approved’ set of plans ‘better/will/should’ know what brand of CCWH is spec’d for the job, and frame accordingly. Now if someone wanted to pay PtP wages to frame for one of these toilets, I would not balk. But because the framing (Photo 9, above) is more involved than just adding or removing a stud or joist, the builder can always frame faster than yours truly, and by a lot. (He was rarely offered the job.) By studying the carrier frame in Photo 10 you can see the spec’d framing is integral (tight to) the carrier. However, “…no time for wobbly knees.” One merely needs a quality circular or hand saw, hammer or nail gun, and a little concentration and patience to create it. Thankfully for the layperson, most of the toilet brands offer free, well-produced installation videos on their respective websites. Carried Away Observe the two CCWH carriers (‘hangers/racks) in Photos 11 & 12. In these cases the tubular, plastic, bowl inlet (smaller) and outlet (bigger) drain fittings have black plastic dust/debris plugs in place. Both carriers have similarities. (Dust/debris plugs are yellow plastic in the other.). They both utilize thin wall square steel tube in their manufacture. Both have adjustable feet to allow the installer to achieve a custom height for the rim of the bowl. That’s a big deal. If you were another Wilt Chamberlain, you could have the toilet ‘way up there’ on the wall because the legs are standard square tube and easily modified. The dimensions of the poly flush tank (cistern) yours truly believes is where the designs begin. There has to be a ‘certain’ amount of water (derived at by a smart person) at a certain height, to attain velocity to flush the bowl. Cistern shapes differ among manufacturers. The tank/cistern is the size it is due to physics, plus it has to satisfy the need to ‘pancake’ into as little as 2x4 framing, on some models. Note: Some CCWH toilet manufacturers offer a carrier even for a 2x4 stud wall. PtP would recommend ¾ ply on entire wall, to hang a toilet on a 2x4 stud wall. The 3-in plastic Schedule 40 drain pipe serving the toilet will eradicate the full width of 2x4 lower plate/s. Water In…Waste Out The water supply to some makes and models of these fixtures incorporate specialized, usually copper and or brass, parts which are supplied by the manufacturer as integral to those others of the carrier (Photo 11, above). Also, the proverbial “flush handle” or “trip lever” in the case of a CCWH is a panel (Photo 13). Pushing on the ‘buttons’ results in activating parts (little hooks) which travel vertically up and down, lifting linkages to the flush mechanism below, in the tank. These linkages (moving parts) are behind the finish wall on an installed CSWH toilet. As a plumber with deep repair experience, this makes me a little nervous. I feel more comfortable when I can switch out a fixture's components or even the fixture itself without having to bother a wall. Flat Footed Photos 14 & 15 focus on the adjustable feet of a CCWH carrier. The installer sets the height of the bowl by what he/she notes on the approved plan; or, if desired, by drilling one’s custom positioned holes in a carrier body and adjustable leg, any height of bowl could be obtained. However, if the bowl height was radically different from the range of standard toilets it could become an issue if/when the sale of the property was initiated. If it meant however the ease and comfort for the long term use by a physically challenged property owner the decision would be an easy one. The Real Business There are two places (smaller one above the larger one) where tubular (plastic) pipes are inserted into the carrier (Photo 16). These fittings are proprietary thermoplastic fittings which are part of the ‘kit’. Into them go the trimmed-to-length pipe (for the particular thickness of the finish wall of a particular bathroom. (Rough stone?, custom tile?, plastic laminate?, mirror?, smooth drywall? All will differ.) Now notice the two openings in the back of the CCWH toilet bowl in Photo 17. With proprietary rubber seals on the ends of the trimmed-to-length plastic pipes, a waterproof seal with the vitreous bowl on final assembly is attained…(See videos, by manufacturers, on YouTube.) Now look at Photo 18. The Schedule 40 PVC drain protrudes up through the lower plate with remaining wood around the hole, because the framing is larger than 2x4 stud wall. Another look at the photograph reminds the reader that the drainage continues out and down. To where? Straight down the wall to a lower story bathroom to pick up more fixture units before exiting the structure? To a crawlspace under a first floor before turning horizontal? What about those with slab foundations? On new construction or additions slab is ‘no problema’. What about a remodel on slab? Well, Photo 19 & 19a tell us that with enough money to throw at it, builders like Ed Marciniak (E/M Design) will happily saw up your slab foundation (and put it back) so you can have a CCWH wall hung toilet. For those lucky readers with the budget to ‘do something’ with, there are some facts PtP wants you to know about before you get your hopes up, too high. Seat of Power Due to the many more different shapes of CCWH bowls, (Photo 4 above is an example), each model has its own uniquely shaped seat. Specialization always colludes with increased cost. A replacement seat can command a hefty price because there is only one manufacturer making it. If you have the bucks to afford one of the real ‘spacey’ toilets, like Photo 4, you might think about also picking up a replacement seat (now) and putting it away for a rainy day. Availability could also be an issue, way down stream. Another aspect of the above sub-head (Seat Of Power) is just that: Power. In this case, electrical power. The ever more popular bidet seat that has all the “bells and whistles” needs electricity. Most CCWH toilet manufacturers offer a custom bidet seat to fit their particular bowl shape. Bowls so equipped will have integral plastic tubes (conduit) incorporated into the hanger for water supply tubing as shown in Photo 20, below. These conduit tubes are preformed or are ‘easily bend corrugated’ and come as a component of the carrier. For the person wanting a CCWH with an accompanying custom bidet seat (from the same manufacturer), the carrier (for such) most often will be supplied with these conduits so there will be no exposed electrical cord or water supply tube to spoil the aesthetics of the design. Often then there is no adding a bidet seat as an afterthought (without having exposed cord and tube if you could find one to match the bowl). In the framing plan upstream you’ll notice an electrical outlet on the lower left. This location may differ between brands (on whose models of bowls are ‘drilled’ (cast passageways) for electrical cord and water supply for the proprietary bidet seat). Photo 20a is an example of a custom bidet seat made by the manufacturer of the toilet. Well, that’s about the shape of the article the author had in mind. But before closing this piece he wanted to share some general concerns/facts about CCWH’s that might help a reader decide whether they might want to paddle down that stream. Job Site Realities PtP asked his San Francisco son building contractor (Baywardbuilders.com) what comes to mind when he thinks about Concealed Cistern toilets, and what he shares with prospective clients who inquire about them. Dan mentioned the following topics. They were all familiar to the author. As follows: Space CCWH’s can save as much as 9 to 10 inches of floor space. That is crucial for ‘tight’ bathrooms. Hygienics CCWH’s make clean up a breeze. No more toilet base to clean around – mop glides right underneath the whole thing. Also, no joint space between tank and bowl for moisture to collect and fester. No more condensation from porcelain water tank contributing to dank bathroom conditions. Ergonomics Adjustable legs on wall carrier allow for fine tuning of your preferred toilet height. No longer limited by factory options. Noise Rushing water noise from plastic tank [cistern] in the wall emanates from behind the flush control plate on the wall in addition to the typical toilet bowl flushing sounds. This is potentially louder than some of the quieter tank toilets with porcelain tanks. Installation Considerations/Challenges CCWH’s are ideally suited for new construction bathrooms or full remodels because you need to fine tune the wall framing for the particular wall carrier unit. Even with slimmer 2x4 wall carrier models, you may still want a 2x6 framed wall. Although doable with 2x4 stud wall, it gets tricky at the bottom where the drain discharge pipe penetrates the floor. On Geberit brand carriers, the discharge pipe actually protrudes into the plane of the of the wall board that gets installed over the carrier (causing a very slight bulge). In tile wainscot situations, the tile will ultimately cover the drain pipe, while sheet rock will result in needing a gap and a ‘thin veneer’ of drywall ‘mud’ at this juncture (instead of a ‘full thickness’ of wall board/sheet rock). Alternately, by using 2x6 wall [or deeper] instead of 2x4, you can install the carrier back another ½-in. or more, placing the discharge pipe safely into the wall cavity behind the finish wall board AND it allows you to install plywood backing at the bowl mounting area to increase rigidity of your wall and reduce flex movement of the toilet bowl. This is crucial for tile wall wainscot applications where tile or grout may crack from any movement. Setting the carrier back further into the wall cavity also reduces sound transmission by preventing direct contact between plastic tank [cistern] and the wall board. This will also allow for packing the wall cavity with insulation for even greater noise reduction. O-ring Sealing To insure perfect sealing of the plastic inlet and discharge pipes (of the carrier) to the behind the toilet bowl cavities, be sure to employ high quality plumber’s ‘grease’ (Photo 21) or even consider using a ‘touch’ of silicone sealant (in lieu of) to ensure a long-term water tight seal. In Closing The employment of CCWH’s sometimes lets one create a full bath out of a half-bath, or a different, square foot challenged space. Photo’s 22 & 23 by Baywardbuilders.com, show how a small half-bath (plus sharing a junior portion of a small adjacent closet) was remodeled to a full bath (Roman tub included, with shower) complementing a residence with two other full baths. By employing the CCWH the hair care demands of a four person household, three of which maintain long hair, makes life much easier. Well, that’s going to be ‘it’ for this topic, for now. I hope you don’t feel cheated by your time investment. With luck we’ll both ‘be here’ in several more months, when this old man finds inspiration to put another one “In The Pipe”… PtP

0 Comments

|

Author

Peter Hemp is a San Francisco East Bay residential plumber and plumbing author and former R & D steam vehicle plumber. His hobbies are ocean kayaking and touring the Left Coast by bicycle. Archives

September 2021

Categories |

|

|

Copyright © 2017 - 2022

All Rights Reserved

All Rights Reserved

RSS Feed

RSS Feed