|

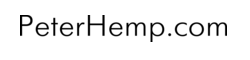

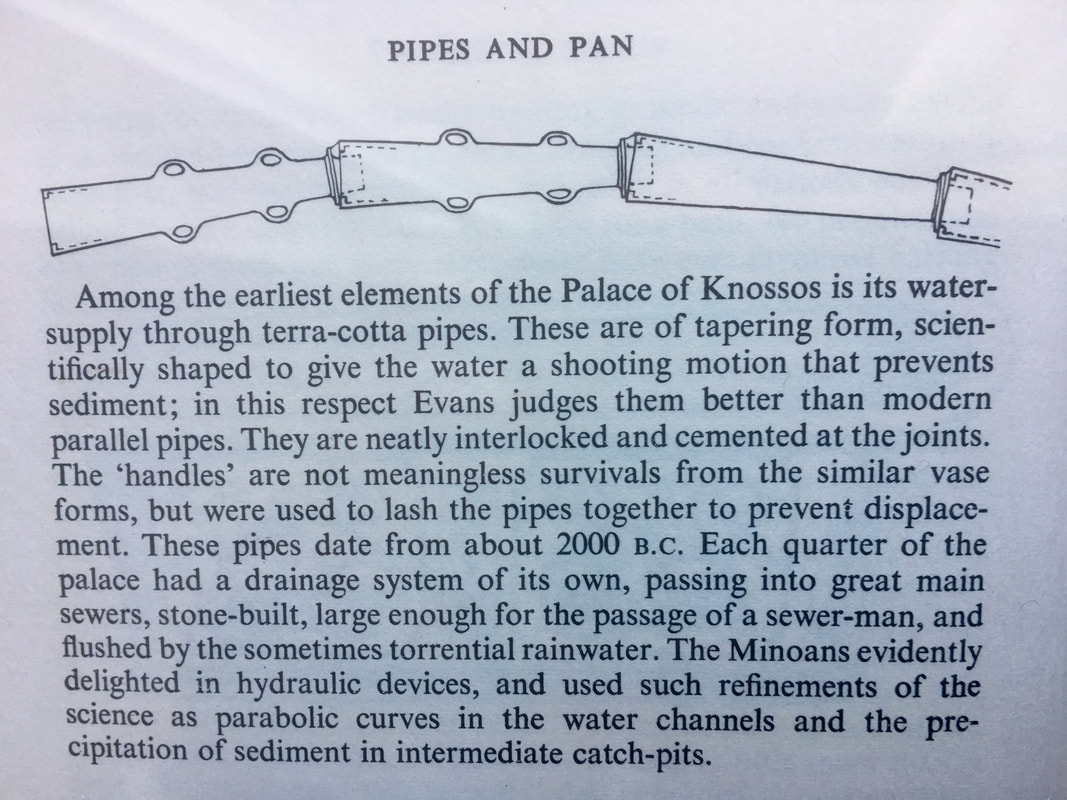

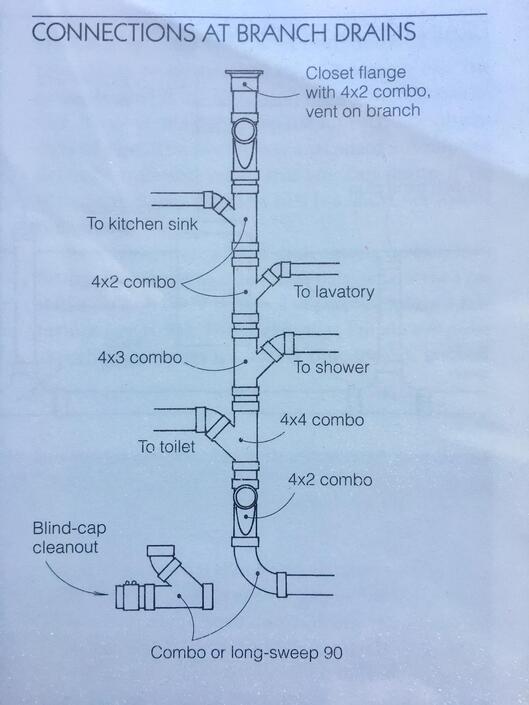

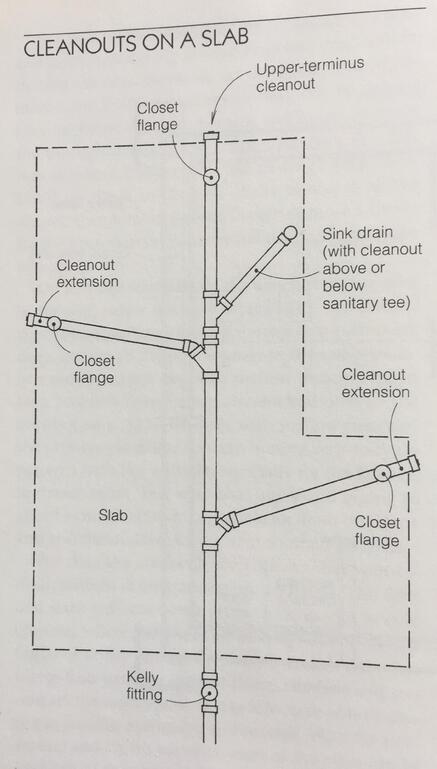

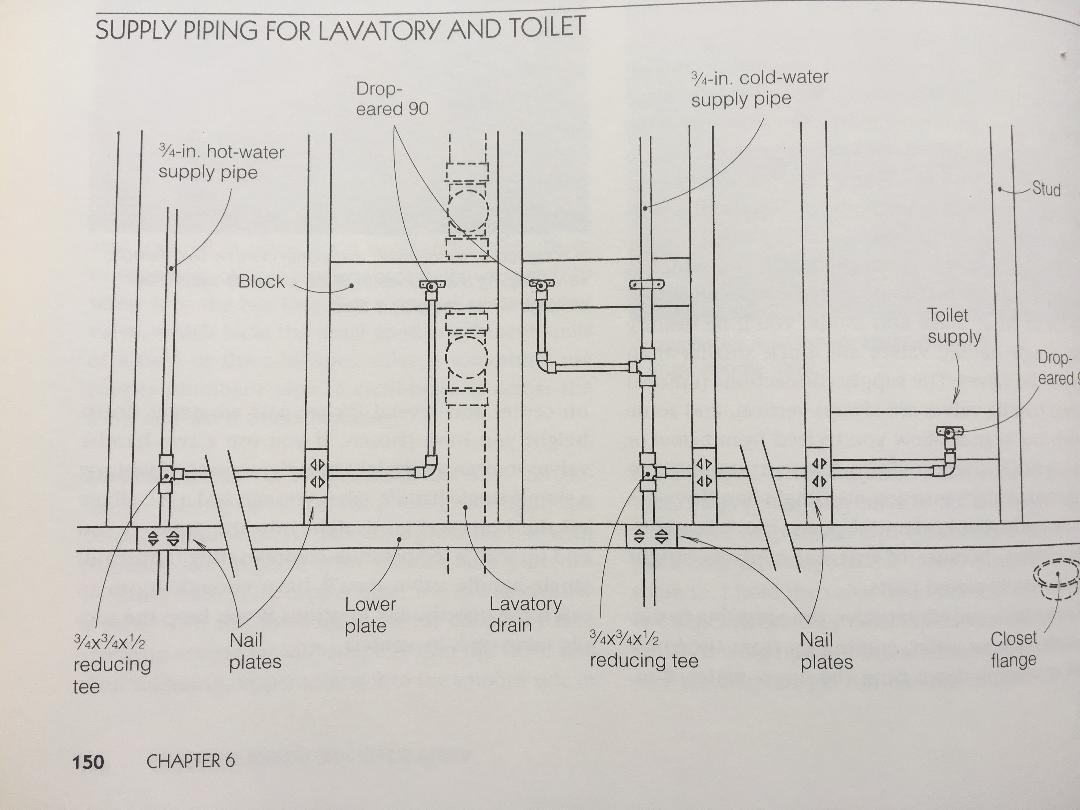

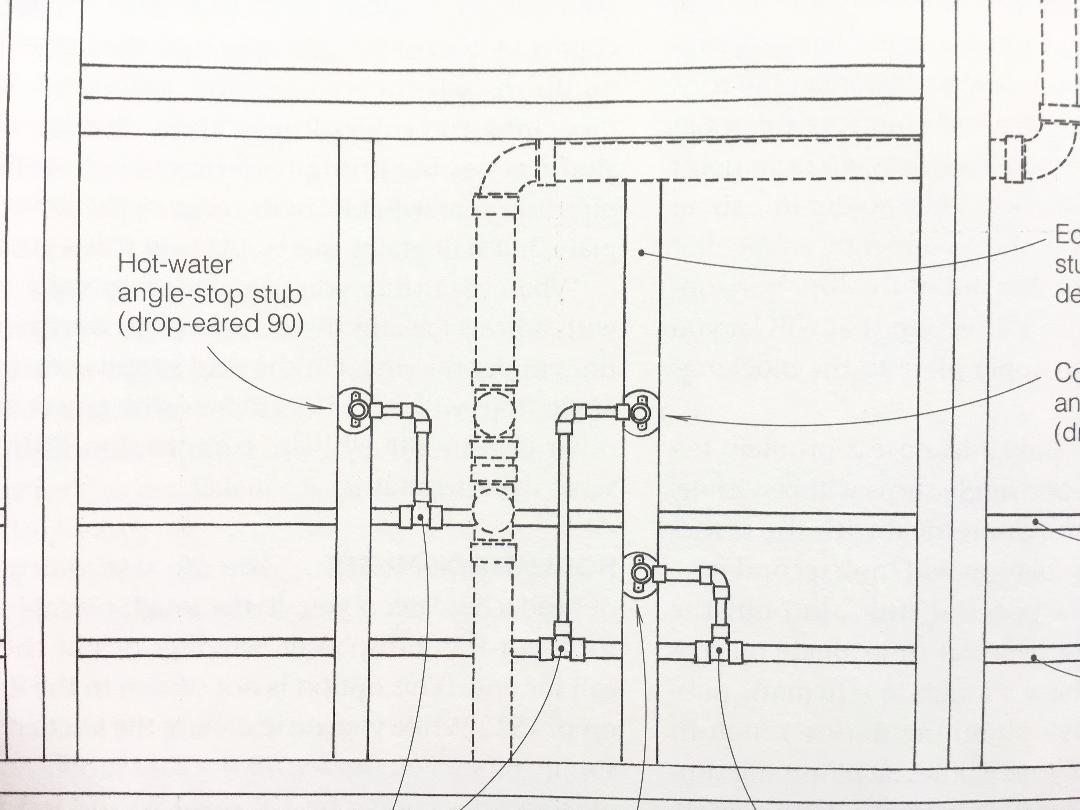

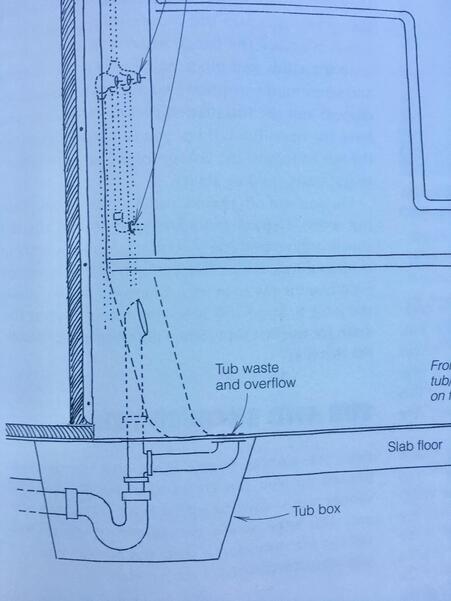

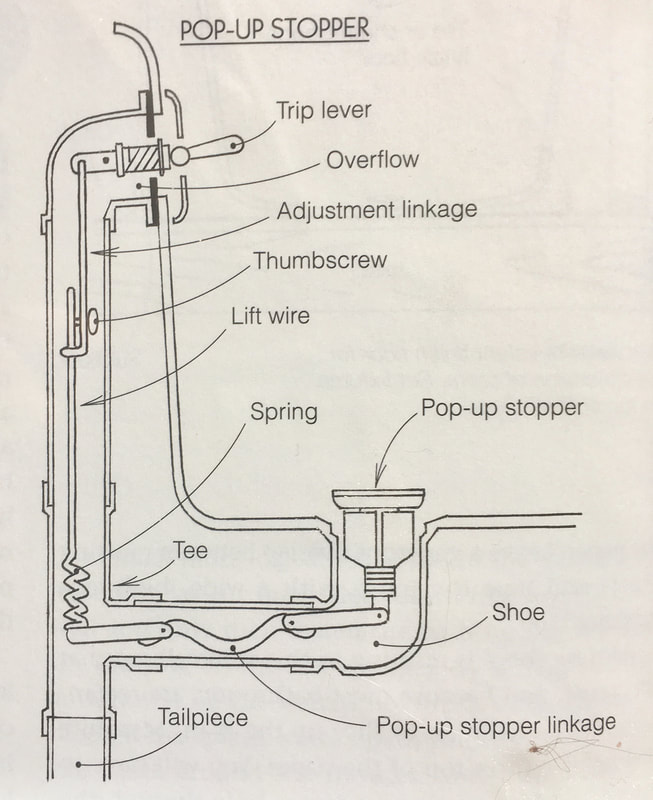

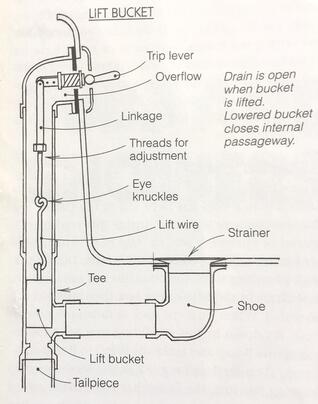

As PtP has mentioned in past writings, Thanksgiving is for Plumbers/Drain Cleaners what Black Friday is to retailers. ‘Our’ (actually your) stoppages are their televisions. Plus, during/every Thanksgiving family feast, we know there will be, somewhere, too many volunteer kitchen hands (for the size of the kitchen), with fingers moving too fast. Poor kitchen sinks. Poor overworked now-dead disposers, poor folks. This is the major event, this is the biggest lesson on discovering the ‘red button’ on the bottom of the disposer. However, family-centered plumbers, at home, on that day, would gladly forgo the opportune wages so as to remain free, to enjoy the company. (I wonder if ER physicians and nurses feel something similar.) But, we push away from the table, put on our coveralls, grab our caps, and go to someone’s aid (because most often it’s one of our dear, longtime customers). Because it’s that time of year, again, the author picked a topic he thought was timely: Stoppages. Since man has been sending water and waste (human and otherwise) down piping, stoppages have been a bane. (This is primarily the case for drainage, but supply, at a utility level, can also have its moments.) In this post PtP will give you his ‘overview’ of the topic, as they pertain to residential structures. This will not be a ‘how-to’ session to unclog drains. (That would be a book in itself.) Here the author aims to isolate and illustrate the common stoppages people experience with residential Drains, Waste & Vent (DWV) systems, inside walls, under floors and in ceilings. We will also take a look at Continuous Waste stoppages: involving piping connecting sinks to drain lines at the walls. (Garbage DISPOSALS included.) This is followed by stoppages involving bathtub waste and overflow (W&O’s), Shower Pans, and lavatory basin Pop-Up Wastes. Lastly, we’ll take a look at stoppages of the toilet. Pushing Off and No Rocking-the-Boat Photo 1 is a drawing snatched from that wonderful book, “Clean And Decent”, by Lawrence Wright. This screenshot illustrates some very sophisticated pipe technology from about 4,000 years ago. What the author here wishes to share with you is this: this piping design is self-cleaning! The Minoans, the inventors, had an extremely advanced culture dealing with plumbing and sanitation. Skipping ahead to the present, our DWV stoppages occur for two reasons: the piping is not/no longer ‘sophisticated’ enough to do what is asked of it. And/or: its physical condition has suffered so badly since the time of installation that it needs to be repaired or replaced. Pete the Plumber over the years has had the honor of plumbing many ‘top drawer’ edifices where he was tasked with creating the best plumbing systems the coin of the realm could produce. Not exactly Carte blanche (“….we trust your judgement…”). PtP’s ceaseless DWV goal was to create a system of: ‘Never A Stoppage’, a system that occupants never need worry about experiencing a stoppage. Did this cost more than any other code approved method? Unquestionably. A lot more? Not necessarily. Plastic (PVC and ABS) DWV systems can be assembled quite quickly when compared to those of DWV copper and no-hub cast iron. Sometimes due to story height regulations, a community will not allow ‘plastic’ above a second story (fire hazard). But code approved ‘hybrid’ systems (a mixture of two or more DWV possibles) are still much faster than an entire cast iron or copper system, which is also greatly reduced in price compared to copper and iron (pipe and fittings). A proficient plumber knows how to “take the extra step” and create a superior job with only a modicum increase in charges. Alice’s Mushroom I was a little boy. I can’t say the exact age anymore, maybe 4 to 6. But, methinks “Alice In Wonderland” would have been a prevailing influence on me then. I remember watching my father and grandfather plumbing some drains on the farm…I was mesmerized by the fittings, how smooth and heavy they were. I have a hunch that Alice’s magic mushrooms came into play. I was soon envisioning myself like a tiny bobsledder, flying along inside the ‘dad’s’ pipes, sliding and twisting, dropping, dropping, dropping…swishing this way and that through the fittings, in pitch blackness. Flying along at those speeds you wouldn’t want to meet up with a stoppage. If Only Tradespersons (all disciplines) applying their skills to a brand new structure, have the singular opportunity (if they so choose) of doing the ‘little’ things that make “all the difference in the world” in the efficiency of their creations. The extra cost for this level of service is usually the difference between a low bid and one of the top three. For the life of the structure, though, the extra cost is ‘peanuts’ for the extra measure of workmanship attained when weighed against the cost of drain maintenance. For example, Photo 2 is another screen shot, one from “Plumbing A House”, Pg.127. A HUGE advantage for attaining ‘no stoppages’ is running every possible drain line individually, as PtP did in the drawing. The kitchen sink, the lavatory bowl and the shower connect to the main building drain as single drains. When branch drain lines must attach to other branch lines (for architectural anomalies) on their way to the main building drain (MBD) PtP, when possible, increases ‘downstream’ pipe size (code required or not). Also try not to join laundry machine and tub/shower branch lines. (We will get into the reason why further downstream.) And, most importantly, when ¼-inch per foot fall is maintained on ‘horizontal’ drainage lines, the risks of a stoppage are reduced. It has been determined that the ratio: ¼-in./ft. is the most efficient degree of slope (angle) for successfully transporting solid waste in ‘horizontal’ drain lines. Any steeper and the liquids race ahead of the solids. Too little slope and the needed volume and velocity of the waste water to carry solids, slows to the point of stopping, and oops…a stoppage. Repair work performed on existing ‘mature’ DWV pipe systems can be a lot different than installing new versions in either a new building or a remodel project. If the plumber of the original structure did ‘only- enough-to-pass’ (inspection) level of workmanship, sometimes, plumbing-wise, succeeding tenants/occupants will unfortunately have to be inconvenienced in both lifestyle and budget by the cost of drain cleaning contractors, sometimes on a maintenance schedule. As the author quoted from the Uniform Plumbing Code (UPC) in his book “Plumbing A House”, the Code is a minimum level of workmanship. A well designed and executed plumbing system is the mark of a plumber’s plumber. And, if you live/lived day in and day out, for years, never having to even think about stoppages, you can bet a few extra ‘extra-steps’ were taken by your installing plumber. DWV Stoppages Is there any one fixture responsible for a majority of stoppage calls? The author cannot claim he knows. Consumer grade/wide versions of toilet plungers (plumber’s force cups*) stand near a whole lotta toilets. But there’s no other specifically designed one-piece hand-operated ’un-stoppage’ tool for showers and or tubs and sinks that doesn’t require taking ‘piping’ apart. Is that a clue? Whatever is the case for those on off-the-ground foundations, let’s ‘first shine a light’ on the main building drain (MBD) the biggest drain in the structure. The ‘sewer’ lateral (pipe) is not found under the structure. It begins two feet away away from an outside wall of the structure. *Force Cups are commonly employed on tub and tub/shower stoppages and on sinks when their shape near the drain opening permits. Have you off-the-the-grounders (OTG’ers) ever ‘given a look’ at your structure’s main drainage lines? Are there any noticeable ‘sags’ or sagging at branch fitting locations? When the installing plumber creates an off-the-ground drainage system he/she is required by code to support their piping every so many feet, both horizontally and vertically. This support distance differs between pipe size and material composition. Schedule 40 PVC pipe is much heavier than Schedule 40 ABS pipe. Such a basic exercise (supporting piping) has a really big part to play in future, trouble-free operation. “Never too many straps” is Pete’s mantra. It’s the same for buried pipe (slab). Here, backfilled earth is supposed to provide support for plumber established grade, on piping. If/when the ground shifts enough, the MBD system can sag. Even inspected and ‘signed-off’ systems can have flow problems over their lifetimes. Just a little sag in horizontal lines, over time, can create enough ‘left-behind’ residue to slow down drainage to the point of a stoppage (Murphy’s Law: at the worst possible time). Clearing stoppages occurring in drains and wastes supplied with convenient cleanouts (CO’s) are much easier to manage than the ‘take-apart’ or ‘cut-into’ solutions. Pre-history When PtP entered the trade, DWV for residential construction was bell and spigot cast iron, joined with compressed oakum and poured lead. Support for this pipe material was ultra important because of its very heavy weight and its wont to sag at unsupported joints. Many buildings still providing habitation were plumbed with ‘corked iron’ (bell and spigot/lead and oakum), Photo 3. It’s not only drainage piping that can ‘sag’. When a foundation fails, (quite common) piping hung from now-sloping floors, ‘sag’ or shift along with the structure. Bell and spigot cast iron pipe was especially prone to horizontal sag when buildings failed to remain plumb and level. Stoppages can be attributed to both negative and excessive slope on runs. The author commonly sees broken and missing support straps and brackets when crawling under buildings, which afford both situations. For someone faced with too often-a-need for an in-house MBD drain cleaning service, in a building with an “off the ground” foundation, the author would first suggest checking for proper slope on the MBD. Those with slab foundations and ‘snake-camera’ friendly access to the MBD, can perform inspections from the inside of this largest of drains. Pete sees an analogy between old people’s arteries and the sanitary drains of old housing. Both tend to clog up with age. Another analogy is the fact that what coursed through their ‘veins’ had an effect on their longevity. Homo sapiens sapiens, aside from clogging their own arteries with junk food, are known to disregard what (other than human waste and TP) they rid themselves of, via the sanitary drainage system: toilets, tub/showers and sinks. The author (now) is never surprised at what he might find (plumbing-wise) in built residential plumbing situations. But, proper pipe sizing, installing and maintaining proper fall on horizontal drains should be the first concern for attaining “Never a Stoppage”. Want to hear a funny story? No? Well…if you don’t, please skip ahead to The Small Stuff section below. When the S**t Hits the Fan One day PtP got a clogged toilet call. The gentleman Pete spoke with had just finished adding a bedroom and a bathroom in the basement of his old house. “We can’t use the toilet…could you come and look?” “OK” I told him…“How about I squeeze you in, late on my runs.” Upon arriving, and with greetings exchanged, PtP was led to the basement. The new bedroom was quite cute. The bathroom, yours truly, was not prepared for. It was more a large closet, where in one corner it was three high steps to the toilet, set atop a plywood ‘pyramid’. “Oh my!” I remember thinking (and maybe even audibly?). This was a brand new vision for PtP. Although outlandishly impossible, I had to chuckle (internally?) and admire the scope of this man’s imagination. The sewer lateral for the existing house (which a new toilet would need to join) ran in the ground, parallel to one of the foundation walls comprising the toilet corner. The owner’s loo was supplied water via an interior, wall-fastened Schedule 40 PVC pipe from an existing laundry sink bib fifteen feet away. This newly installed toilet’s outlet however was still more than a foot lower than the outside, in the ground sewer. Interesting follow-though. He was faced (in his mind) with how to run his combined toilet and wall hung sink drain line either over or through the thick foundation wall, and, how to connect to the sewer lateral in the ground. (That’s why he called the author.) The client assumed, because he was going to be pumping his waste, that he could use smaller diameter pipe: 1½ inch ABS. That is smaller than the two-inch regulation size for a proper sewage ejector and basin. The client was hoping Pete would vet his design and help with the last phase, ‘connecting’. Across the inside wall, for several feet on one side of the pyramid, ran a 1½ in. ABS plastic drain line for the new, small, wall hung lavatory basin. Our amusing fellow poked this drain into the pyramid and then joined to the owner’s ‘brilliant’ waste “pumping” system. What was so brilliant about it? Well, there was no pump in the pyramid. There was no basin in the pyramid. But there was an installed and wired garbage disposer in the pyramid. A garbage disposer! A cheap ‘tract’ model, secured to the toilet outlet. Our amazing old guy thankfully hadn’t been able to make his final connections before my visit. Pete was really sorry when he had to pop that bubble. And the shame? Today that homeowner could have a composting loo without the need for utilities and he would have made ‘home’ for someone else. The Small Stuff Upstream, the author recommended that laundry and tub/shower drain lines, whenever possible, should not be joined. PtP will now tell you why. Most readers, I assume, are aware that automatic clothes dryers produce a modicum amount of ‘lint’ (fibers) in the lint trap as clothes are dried. Well, there’s almost as much or more ‘lint’ going down the laundry drain with each cycle of the washing machine. All by themselves these ‘fibers’ wouldn’t be much of a concern for properly sized ¼” per foot drains…but even better would be ‘home run’ drains to the MBD. However…when you think about what is the effluent of tub/showers (aside warm water), it’s an “Uh Oh” moment. All manner of chemicals and compounds are applied to human bodies before/as they bathe. Shower and tub/shower drains (depending upon lifestyles), can/should leave only an immeasurable amount of particulate/residue behind (to add to an ever building inner layer of “sludge”). Now, that’s a big enough concern all by itself, but WHEN you mix ‘fibers’ and ‘sludge’ together, over time, the ‘liquid’ waste, in some cases, can be described as “liquids on steroids”. Or, “pushing the definition of liquid.” What was once a pipe diameter the thickness of your arm, eventually, has the inner drainage diameter of that of a broomstick. To clean out sluggish, joined, ‘minimum code’ laundry and tub/shower drain lines, in habituated space, is somewhere between “Well, let’s see” and a nightmare. For only a few more shekels spent on the DWV installing plumber (CO’s) this problem might never have arisen. On ‘off-the-ground’ foundations original mistakes sometimes can be reversed, or at least ameliorated. For first/single floor ‘slab’, like the present majority of new housing in suburbia (tract), any below grade ‘committed sins’ are ‘cast in stone’. Pete the Plumber’s got his jackhammer. But, “We both don’t want to do this.” Sometimes architectural anomalies (for both new and remodel) can throw ‘the wrench’ into an otherwise ‘perfect job’. In these cases we can only try to give up as little as possible, and minimize the the inconvenience of a future stoppage with well-placed cleanout accesses. Photo 4 is a top view of a hypothetical main building drain layout suggested for slab, with conveniently accessed cleanouts. Page 134, “Plumbing A House”. (This would also apply for minimal ground clearance ‘off the ground’ foundations.) Photo 5 from “Plumbing A House” illustrates a lower, super-handy, cleanout tee and threaded plug for a lavatory basin drain, page 150. Photo 6 shows a cleanout tee and threaded plug for a kitchen sink installation, page 152. If it took the plumber an additional ten minutes of labor time, at $150 per hour (for each fixture) and a cleanout fitting expense of $10.00 for each fixture, you’re looking at a sum of $35.00 difference, for each installation, for a guaranteed savings of hundreds of dollars for having a plumber first need to remove and then re-install the under sink waste piping (where no cleanout exists) before and after needing to mechanically clear a clog, adding to the bill. Note: PtP had special fun discussing one of the all-time sneakiest kitchen sink clog causes, in his children’s tale: Pete the Plumber Meets Arnold The Anteater. At work, how many readers (not Maintenance Staff) have been required to use a plunger before or after you could use the loo? At home?...a raise of hands? How about when/because of a garbage disposer, your sink takes minutes (or more) to drain? After ‘needing to address’ exceeds a ‘certain number of times’, life is not so much fun anymore. Competing Nemesis’s The author would now like to share a plumber’s concept with the reader that is usually not common to many laypersons. Plumbers view a structure as having two, distinct building phases: Rough and Finish. Plumbing activities involve both. Stoppages are inherent to both. However, correcting for causes with rough is many times more difficult than correcting problems with finish. Think of rough plumbing as all the pipes hidden from view, in the walls, floors and ceilings. Can you see why repairing or improving this system of piping is so difficult? Getting at it means opening walls and floors and ceiling inside a furnished structure. The rough plumber who designs and installs this system of piping by using just one poor choice or wrong fitting (even if Code accepted for circumstance) can cause every succeeding resident/worker or owner much misery year after year after year. Site and/or architectural challenges aside, the author touched upon the importance of workmanship and sound design of main building drains (above) for attaining “No Stoppages”. Now let’s take a look at the second nemesis: Stoppages of Finish Plumbing, including Continuous Wastes. Tubular wastes (Continuous), our next focus, are commonly repaired and replaced many times after their initial installation by someone other than the installing, qualified plumber. Continuous Wastes offer the ‘unlearned’ or ‘insufficiently inspired’ a dandy opportunity to cause stoppages. Tub Waste and Overflow The most inaccessible tubular waste, and therefore most worrisome, is the bathtub waste and overflow (W & O). (Photo 7) If it is not installed properly it may result in Sawzall and large holes in adjacent walls or ceiling (yours or someone else’s?) or even a tub lift and reset to facilitate replacement of this waste. Needless to say, attention should never waver when selecting quality and installing them. Some W & 0’s are a better long term bet than others, because of better designs and materials. Based on inherent performance and durability (“unadjusted” for human interference) PtP’s preferred choice of tub W & O is the pop-up version. (Photo 8) This waste uses, as does the lavatory basin, a pop-up stopper as discussed downstream. Its major and more common competitor, the “lift bucket” waste and overflow (Photo 9), has a greatly reduced internal passageway, slowing the drain time. (The faster a sanitary vessel drains, the cleaner it remains.) These also have internal linkages of minimal stoutness that wear faster than the rod and spring of the pop-up W&O. But, both types have to deal with hair and residue of the world’s chemists, which will be discussed downstream. It’s a Hairy Question PtP was once consulted by an International chemical company concerning a formula tweak to their top selling brand of liquid drain cleaning compound. They came prepared with clear glass waste tailpieces, p-traps and trap arms in demonstration module/kiosks, whence there was introduced to each module various “usual culprits” for causing stoppages. Then they followed by adding their product. I was truly impressed. Especially after seeing wads of human hair dissolve in front of my eyes. Human (and pet) hair is an extremely difficult opponent in keeping residential drains running freely (especially when it mingles with ‘sludge’. Beauty and health products, and hair (as mentioned above) can create mini, reinforced ‘fat bergs’ (search) in tubular wastes and undersized/under-performing sink, tub and shower sanitary drain lines. Supposedly, if we ‘still have it to lose’, we part with between 100 and 150 strands of hair a day. Of what hair we lose while taking a tub or shower (and not getting caught by any hair catch strainer), has the opportunity to latch on to the slightest waste fitting/drain line imperfections, whether manufacturer or trade related). Internal tub W&O ‘trip-lever’ and ‘pop-up’ W&O linkages are both trouble spots for anchoring and fostering hair snakes (Photo 10). And, other imperfections both manufacture- and plumber-caused, offers ‘safe harbor’ for ‘hair nurseries (which can lead to a stoppage). Photo 11 illustrates how hair, given the opportunity, can form a ‘hair snake’ on linkages and when serious enough, create a stoppage. Lavatory Basin and Pop-Up Wastes Lavatory basins having pop-up wastes seem to be among the ideas the 20th Century successfully bequeathed to the 21st. All that time, different minds have produced various pop-up waste designs worthy of manufacture. Some were/are better than others, but ALL of them are no match for hair. Regardless of design, maintenance is a must, and hair is the biggest threat, followed by toothpaste, beauty creams, cosmetics, shampoo and other grooming products. The actuator arm of the pop-up stopper, serving many designs of stoppers and wastes, is the Gorilla in the room. Knowing how to remove and clean and reinstall this actuating arm without fiddling with lift rods and linkages is a very handy maneuver to know. The author taught his 90 plus year old Mum (mile upon mile away), how to do it. (Saved my Deep Pockets brother “Captain Hemp” zillions.) Garbage Disposers were never one of PtP’s wishes for responsibility, thereof. I can remember with great excitement waiting for my father to finish his second remodel of the family kitchen. Wow! Soon. Mickey (older brother) and I won’t have to wash dishes anymore! Whoa……. What Pete was not ‘clued-in’ to was that this privilege involved an alliance with an appliance called a ‘garbage’ disposer. (The dishwasher’s drain hose connected to the disposer’s grinding chamber and its discharge used the tubular continuous waste to make it to the San Tee in the wall.) Oh though, it was really cool having to only rinse off the dishes before putting them into the dishwasher (‘Iron Maid’). But, the act of putting food scraps anywhere but in the under-sink garbage bin was also weird, not to mention a genuinely, unnerving event. Those first, occasional, errant pieces of silverware foolish enough to enter a running garbage disposer hinted at our peril. We still live with an uneasy ‘alliance’ when it involves garbage disposers. Dishwashers, you fill‘um, start’um, and run’um, even leave them running while you do other things. Garbage disposer operation requires more ‘attention to duty’. Yes, maybe it’s only a quick swipe of melon rinds and (with water running), hit the switch. But as Pete told in his children’s story: Pete The Plumber Meets Arnold The Anteater, just one wrong assumption about your electrical slave (GB) and your schedule will take an abrupt left turn. Many factors come into play to cause/allow a stoppage involving the garbage disposer. If the appliance is in good working condition, and the drain lines are properly sized and installed, and you ‘suffer’ a stoppage at a hosting kitchen sink (KS), the grand jury will rule the culprit has your hands. Something went down that shouldn’t have. Sometimes you can have a sink stoppage caused by and limited to a clogged grinding chamber (and the continuous waste remains free and clear.) Sometimes the clog ‘medium’ passes through the disposer and lodges in the continuous waste, or anywhere on the way to the San Tee of the drain line, or even downstream at some point. Most laypeople assume a stoppage will occur in the trap. Isn’t that what that u-shaped fitting is for? Nada. It’s to keep gases out of your house that could kill you (asphyxiation and/or explosion/fire). Many times when a KS or a lavatory sink becomes clogged, the ‘medium’ is not holed-up in the U-bend of the P-trap. Most often it’s at the San Tee branch and downstream. Question: What’s one’s best hedge to avoid stoppages involving GB’s? Answer: Purchase the appliance as far up the chain of quality as permits; install or have it installed to professional standards; and, don’t feed it anything that you shouldn’t. (See: “The Straight Poop” and other references for suggestions.The list is a long one.) For kitchen sinks without disposers and laundry sinks, most stoppages (as mentioned above) are not caused by U-bend blockage, but rather congestion at the San Tee or downstream in the drain line. After-market, well-designed (and efficient) sink drain cover screens and ‘lint socks’ on washing machine drain hoses are/should be your first lines of defense. Finish Woes Pete the Plumber in his book “Installing And Repairing Plumbing Fixtures” (IARPF) advised the reader while at the point of purchase, to have opened for them, by store/supplier personnel, shipping cartons for their chosen fixtures. Then is the time to inspect each article for damage and quality control issues, before taking them home or to a job. Specifically, for closet (toilet) bowls it is critical to check the horn for deformities and roundness and smoothness of exit. (Photo 12). Photo 13 shows one that got past quality control. An undetected, badly shaped horn could mean stoppages from the get-go. If the new toilet’s horn is not inspected prior to setting, later, when diagnosing flushing problems it must be lifted to settle the issue of horn deformity. There are other toilet quality control issues but they are not of a stoppage concern so, if interested, you can read about them in IARPF. But, when it comes to toilets, minding the 3 P’s rule: “ONLY poop, pee and paper” is your best line of defense for toilet stoppages. Other vitreous concerns lie in malformed, internal lavatory basin overflow passageways, and how well they joined with the bowl waste chamber when they were manufactured. Out of shape and casting imperfections can occur at this junction. When serious (and combined with human error) they can be cause for loss of overflow protection (internal blockage stoppage) and an ‘over-the-rim’ flooding incident (with/when a loss of ‘attention to’…). Outside The Building Perhaps (for sure) one of the major causes of stoppages is thirsty and hungry ROOTS from trees and shrubs. Whenever there are functional, convenient cleanouts (CO’s) many homeowners straddled with either paying for a sewer replacement or a cyclical drain cleaning (depending upon state of the landscape), choose a maintenance arrangement. An old, ‘old plumber’ friend who did a lot of drain cleaning in his life said that after a thorough clearing of sewer laterals having root problems, that the roots could be kept at bay with a cup of rock salt in a ‘last toilet flush ‘til morning’, every night. That makes sense for a homeowner/dweller hooked up to a municipal sewer system. In that case, if one had the storage space and capacity to carry a large, 50-pound sack of rock salt, it would go a long way for postponing the next need of de-rooting service. “Those Varmints”, he said, “Dey just don’t like saline… and…stay away.’ But, for those on septic systems, I’d adhere to the rule: “Nothing But Poop, Paper, and Pee.” For those already on septic and anyone considering switching from sewer to septic, the author HIGHLY recommends reading “The Septic System Owner’s Manual”, by Blair Allen (Photo 14). The knowledge contained can save one from ‘die-off’ catastrophe $$$, and predatory septic snake-oil drummers. Well, the author was going to tell you another ‘funny story’ but he thinks maybe he has already put enough readers to sleep. Happy Thanksgiving…without stoppages. Until Next Time… PtP

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Author

Peter Hemp is a San Francisco East Bay residential plumber and plumbing author and former R & D steam vehicle plumber. His hobbies are ocean kayaking and touring the Left Coast by bicycle. Archives

September 2021

Categories |

|

|

Copyright © 2017 - 2022

All Rights Reserved

All Rights Reserved

RSS Feed

RSS Feed