|

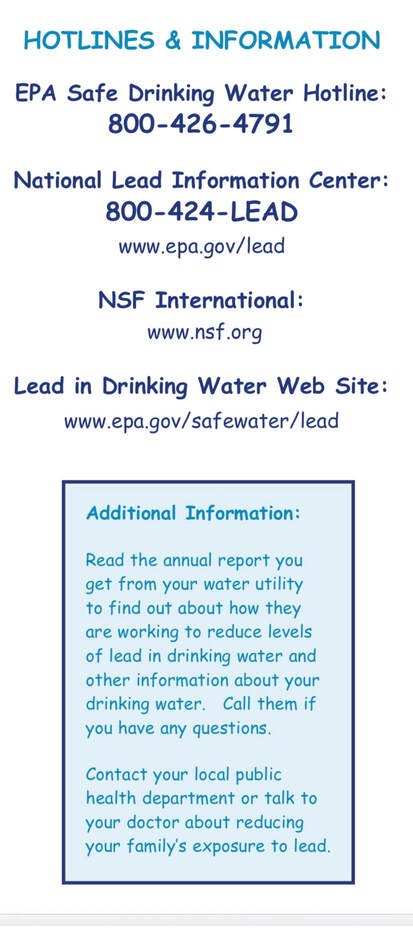

Hello. Welcome back. Long time no-see (hear). The author, Pete the Plumber, like many of his countrymen, have recently themselves been inconvenienced by contracting the Corona virus. Thankfully the author is back on his creaky legs again and looking forward to sharing his take on a very time worn subject: lead poisoning via municipal fresh water agencies’ l e a d service lines; plumber installed galvanized (galv) steel/iron lines; and, lead soldered copper fresh water lines installed in new and remodel ‘living space (up until 1986). During Pete’s recent MVI (mandatory virus isolation) period he had time to think about what subject he’d likely wanna make for his next ‘In The Pipe’. Well. Now, thanks to the recent majority of the 117th Congress agreeing to fund the removal of a l l lead service lines to American housing” (at Government cost) through recent legislation, ‘me fig’erd’ (as a plumber) would make for an interesting, close observation. There are only a few photos this time woven into my story (where I could find examples). Nationally, we still cringe when hearing or reading anything new about the “Flint Michigan Water Crisis.” Poor Flint. (Glad I don’t live there.) As it turns out it did not end there, by any measure. (Neither did it begin there.) Nationally we’re still in deep doo-doo. There are still estimates of 9 million, still-active lead service lines in the Country serving 22 million people. In the author’s estimation (yes, by plumber’s bias), if N O T H I N G else were accomplished during a n y Presidential Administration, “Getting The Lead Out” alone would be a history making milestone. One to really crow about. Now there are funds (allocated) to do just that. You could be among the many privileged to see a truly historical landmark: bye bye to lead in water piping. The AWWA (American Water Works) estimates 5-6 thousand dollars, on average, to replace each lead service line. The new legislation allots a total of 15 billion, and 3 billion has been put in play as of this writing. As encouraging news as it is, I have to remember that the Clean Water Act of 1948 became law in 1972. But hell, I’d take a repeat of that wait to see this campaign finally accomplished. However, as Citizens we a l l should remain cognizant (and vigilant) in seeing what progress and at what speed this comes to be. Very few improvements, if any, could be so immediately beneficial to a society as replacing e v e r y o n e’ s lead service* piping with a healthy alternative. It will be worth carrying a placard, making phone calls and signing petitions when the progress lags. *As you will discover downstream there are still more sources of lead in house piping aside Service Lines (SL). Pb Since our (my) Middle School days we’ve (I’ve) known the Romans were inextricably known for their adoption of lead in various avenues of their lives. The argument as to whether lead was responsible for the decline of the Roman Civilization still erupts now and then. Since Romans were so good at mining and smelting galena ore (source of lead) and making water pipes the author thought their experience with the material merited a casual look (dinner plates and wine goblets aside). The Roman means of producing lead plumbing pipe was simple: pour molten lead out onto a flat stone surface to a depth of desire and then let it cool down. Once cooled, it was rolled into a diameter they wanted and then soldered. Common diameters ran from ½-inch to 22-inch. This piping was used for both water supply a n d drainage (they also lined open conduit of their aqueducts with sheet lead). It’s been estimated that the lead content of ‘municipal’ water in large Roman cities ran between 14 to 105 times that of local spring water concentrations. It’s lead content in “drinking” water that civilization up to the present day lives/has with, that makes the new Congressionally sanctioned removal attempt almost a “Bookie” event. Only more time will tell. The legislation d o e s have a stipulated completion date. Whether Uncle Sam can find the competent leaders and laborers to get this done by that date will be a nervous interim. What’s a mere two or ten years ‘behind schedule’ when this problem has befuddled man since Augusts was ordering more baths built. Who’s Guilty ? Yes. There were a number of Roman elite who knew the health hazards of using lead to transport water. And, the American lead industry funded cover-up campaigns trying to stave off the eventual discontinuation. ‘Our’ lead service lines were installed as late as the 1970’s. Where the water quality is good though, the fewer problems are encountered with lead. The Author remembers the Utility serving his metropolitan area annually dug up someone’s lead service line. It was then cut open and visually inspected and tested for leach. Because of the high quality EBMUD water (Sierra snowpack) (how much longer) lead leaching was not a problem. (It was just Pete and his plumber bro’s using that lead solder and flux that posed the larger danger.) Who…me ? Now it is not without a degree of guilt that the author looks back at his career years, those forklift’s of copper for fresh water systems he assembled using lead base fluxes and solders. (It was ‘the norm’ back then. “I was only following orders”.) Pre-1991, lead-soldered, copper (potable) water systems are one of two major contributors to lead in drinking water today. The author recalls his soldering technique, though, needing ‘tweaks’, to be able to effectively use the first available lead-free solders. Matter of fact, PtP has another anecdote to share on that subject. One day the author was running ‘copper water’ (in Type L) (his default) in a custom addition in the Berkeley Hills (CA) and he was testing several different manufacturers’ offerings of ‘Lead Free’ solder. As it happened during this exercise, Pete decided to ask his client, a metallurgist, what was antimony (which was one newly adopted replacement for lead). “Well, she replied, “Basically, move one molecule just a tiny bit and you have a r s e n i c ! “Whoa!” was my reaction/reply. My client ‘calmed down’ yours truly by explaining that unlike lead, antimony is n o t water soluble. Yes! If I were to i n g e s t it, it’d probably kill me just as swiftly as arsenic.* Plumbers (yours truly included) discovered some brands of lead-free solders and fluxes were easier to master than others. And as this plumber will also tell you, as for ease-of-use, your choice of flux is as critical as the ingredients of the solder. (Flux compounds commonly contained lead prior to the 1986 Amendment.) *After feeling ill late in his career Pete sought medical attention. Hair analysis showed ‘off the chart’ levels of several bad boys: lead, arsenic, cadmium, copper etc., etc., etc. a lot of years of bending solder with his teeth (while lying on his back, under houses) which streamlined the joining process. He breathed years and years of solder and welding smoke with insufficient ventilation. Thankfully a medical process called chelation put him right again. When dwelling on the lead pipe danger issue, the author can’t help envisioning those long ago Roman lead workers, toiling with large pans of molten lead and the polluted smoke. It was a ‘negative’ to make as well as a negative to use. ASTM-MUM (new Roman rating) What the author finds interesting, most, is how did ‘they’ (Romans) figure out what pipe wall thickness could handle what volume and pressures. (And over what a period of time). In Photo 1 we see a cross section of an ancient Roman lead pipe. To Pete’s eye he’d say the wall thickness looks approximately equivalent to Schedule #80 (or a Heavy Duty Schedule #40), two of today’s most commonly specified values for piping in modern construction. The Romans used lead for both supply and drainage. Today’s construction industry’s lead worries are supply issues (existing lead/copper systems). It is when water is delivered in lead piping and then INGESTED that is the issue here. Showering with lead tainted water is not a palpable thought but much less worrisome than drinking it. Knowing how Epsom salts can affect his body, sit-down bathing in a tub with high lead concentrated water is something Pete would avoid if possible. Keeping an eye (trying to) on the impetus for this article (new Federal efforts to eradicate lead potable water pipes) (Service Lines), it’s the ‘service’ portion of the water line that is our focus. This is piping that the Water Service provides/uses to take ‘their’ water to the connection point (meter, outside) with the customer’s Main Water Line. From that point it’s the customer’s responsibility to install and maintain water lines. As you will be reminded downstream the Feds are not offering help re-piping housing, which is/can be another source of ‘lead in potable water poisoning’. We are going to focus on the former, the ‘water service provided’ lead (service) plumbing. Why? Because that’s where the money is supposed to be spent. Replacing, replacing, replacing. (The costs of structural re-piping, for many homes makes it ‘out-of-the-question’.) (Read on for a remedy.) Money Colors Everything Would/does anyone ever wonder why lead pipe would still be chosen, for this span of ‘Augustus-to-us’ knowing the health risks? Since antiquity? We plumbers know why: Until very lately, until bendable ‘plastic’ piping was certified for use, plumbers either cut threads on rigid pipe and used ‘change-of-direction’ fittings, or they ‘bent to their need’, this (lead) already century-proven piping material. (Go around the tree. Go under the boulder.) If given a choice who of us wouldn’t want to take the less laborious route? Lead lasts a long time in a large range of aggressive soils. It can be bent and shaped. With soldering, any length of pipe (without mechanical couplings) clan be assembled. (Labor saving). But because we k n o w there is no safe level of lead in children’s blood, the battle remains, in progress. With modern materials the remaining (known) (9 million?) lead, in-service “service lines” can, thanks to the 117th finally start being retired and replaced. Hurrah! However, to rid our present housing stock of it’s lead transporting FWD drinking water piping (Fresh Water Distribution) the author fears is only going to progress as individual properties decay to the point at which they are condemned and re-built. (Another Agustus-to-us time span?). One foot in front of the other! Let’s take the money and get the “in ground” replacement done, behind us, like Augustus. Then the momentum might speed up getting it outta the FWD. (Our reward might also include more ‘Einstein’s’ per 100,000.) SWDA The first Federal Drinking Water Standards were established in 1914. They were standards of Bacteriological Water Quality. Finally, Congress in 1986 amended the 1974 Safe Water Drinking Act which then mandated that solders, fluxes and pipes were “Lead Free”. That term Lead-Free, at this point in time, a c t u a l l y meant solders AND f l u x e s contain no more than 0.2% lead. And, pipes, faucets and valves (tub & shower) were now limited to an 8.0% lead content. (California though lead the way (yes, pun) requiring these limits the year prior (1985). In 1991, the December 1970-EPA (Environmental Protection Agency) published a new edict, the: LCR rule (Lead and Copper Rule).* *This rule was expressly focused on End Of Use Taps: fresh water faucet and valve spout - water in inhabited space. This rule coerced water suppliers to timely test the drinking water (usually annually) a n d if more than 10% of sites tested above 15pbb (yup, that’s billions) of lead a n d/o r 1.3ppm (per million) of copper, the system provider had to take actions to control corrosion [on their dime]. This term corrosion has a sinister handicap which will be illuminated below. Water Systems/Providers, besides chloramines, infuse other chemicals (Orthophosphates) into Supply, to coat the lining of their pipes, offering protection against various biological pests. But, the corrosion layer (rust) lining iron pipe (inside your house) absorbs chlorine, which then has insufficient time to kill bacteria. Too soon after infusion: Microbes party! *The orthophosphates the Water System (water provider) introduces bond with lead to form a protective inner ‘coating’ on the walls of the piping. Depending upon the quality of water flowing through such lead pipe, this intentionally formed ‘coating’ of orthophosphates, does, to an acceptable degree, maintain a ‘potable’ rating. Safe for human consumption. Where trouble occurs is when waters are not benign, when waters are what is termed aggressive. This tag results when water contains (or is missing) any number of minerals and/or chemicals, which can prove injurious to the piping. It’s when aggressive waters flow through lead piping and reduce/destroy the introduced protective orthophosphate liner that creates the biggest health hazard. This is what happened to poor Flint, Michigan. A change in water suppliers, from a long time purveyor of quality product to a ‘discounted’ situation, for a poor product. The ‘switched-to’ source water contained aggressive elements that not only ate away the protective orthophosphate layer in lead service lines, allowing for continuing leaching of lead, but the corrosion of iron pipe ‘inside-house-freshwater’ piping consumes/d the chlorine added by the Water Service to control bacteria such as Legionella. Poor Flint took a ‘two-punch’ to the head. A lot more lead and less protection from dangerous microbes. Why the Corrosion? A common cause for corrosion can be poor water quality. Aggressive waters attack metallic (iron) and copper water lines. Copper less so. (PEX, none). If you wanted/needed to do something now while waiting for Uncle Sam to put on his coveralls and get on with the job, you might consider a counter top filter or distiller. They are made to satisfy as few as one person per day all the way up to a whole family of seven. Just make sure your choice meets NSF Standards for removing lead. (A good thing about distillers is they also solve many more problems with micro organisms than filters.) You can call the National Safety Foundation International’s Consumer’s Affairs Office and ask if your possible choice made their list. 1 800 673 8010 KTP (Keep Their Promise) It’s going to take some time before we know if the money and energies promised, come to pass. In the interval if your water quality worries you, you can get it tested, free. If you are worried enough about water quality that you already purchase bottled water, regularly, at COSTCO, y o u should be making it yourself with a distiller and not contributing to plastic pollution. There are some aspects of the lead pipe chosen for FWS (Fresh Water Service) that PtP would like to elucidate. From elementary school many of us recall learning about the ancient Romans’ wide and enduring use of lead for the fashioning of water pipes. For the same reason it served the Romans it served Municipal Water Authorities through the Twentieth Century. If, found in that time, would you or the author have made any other demands for an alternative material? Why should we have? Lead was what had been/known for centuries, to be the easiest to install and the longest lived in-the-ground metal (economically speaking) available for municipalities to employ. If, in enlightened modern times, adding ‘modifiers’ neutralized the leach worry/question, why stop? In a way it was an amazing piping material for its time. Today we have no excuse for using it due to ‘plastics’ behemoth development, and availability (distribution).

Down the Drain Thanks to all of the former battles of clean water movements and legislation, the lead-solder fight has been ‘put to bed’. The next ten to twenty years will present a scary number of challenges to our fresh water infrastructure. But, at least we can say, today: “We got the lead out of solder”. Now thanks to the 117th, society can finish the job and finally send lead service lines down the drain’, for keeps. Flushing (No, not New York. Or your toilet) For those readers who are concerned about the probability of their living with a lead Service Line (or know they are) OR copper/lead solder/flux assembled Fresh Water Distribution piping, or old high lead content brass faucets and valves, until your situation is physically remedied, flushing is your most effective option. Efficient filters, stills, and Reverse Osmosis options unfortunately are financially out of reach for the many folks who need them the most. For them ‘Flushing’ is their only option. Because we are in the early stages of a ??? thousand year drought cycle this ‘lead’ question comes at the worst time. (I might get an argument from ancient Romans.) Here we’re supposed to be conserving water and now we’re being told to let the water….run? We need an answer. Answer First order of business: Try to find out IF you do indeed have a lead Service Line. Some cities and Water Providers have documentation. Many more don’t. Sometimes it requires expensive detection instrumentation to tell if a pipe, in the ground, is lead, or not. (The electronic gizmos to do that can look really neat….like some sort of Sci-Fi hand held weapon.) The lucky un-lucky can find or expose enough of their Service Line to physically determine (with a flat screwdriver or scraper) whether it is made of lead. O.K. Thanks to your scraper, we now know yours: lead. (Don’t panic.) ‘Let’s go further and see what your house piping is (Fresh Water Distribution). By doing some observations at various locations of your water system (maybe a little crawling). (Oh Me! In my brand new Carhartts): You have threaded galvanized with a shorter, newer, short copper section. Galv pipe and fittings have no external rust. Copper sweated fittings are joined with leaded solder, the dirty old ‘50/50’. O.K. We know you have a lead Service; original threaded galvanized; mixed with lead-soldered copper. What about the faucets? Pre-1991? Yes? Served by a Water Service? Yes. Thank you. Looks like you have a case of worthy concerns. Estimates, by Public Health agencies, of flush times for a housing situation with above listed liabilities would probably be two minutes. So, we leave a faucet running for two minutes until we drink that water? What about laundry? No lead worries. Use/do early in the ‘awake cycle’. Taking a shower? No lead worries. Do at your leisure. Where and when in your awake cycle will you (and family) be drinking tap water? At lavatory basin, after brushing teeth?; in breakfast beverages? The Author’s suggestion would be to ‘use up’ (through appliances) as much as possible, the stagnant, overnight supply before beginning the ‘water contact’ of your awake cycle. That would include dishwashers along with clothes washers and water softeners. Because of continued sophistication, some appliance manufacturers can offer appliances so specialized that the ‘possible buyer’ will have to brush up on their IT. That’s wonderful. But that won’t solve our challenge. The price tag is beyond the masses’ means. Tabletop distillers? Wonderful answer if one has the dinero. We should/need to be looking for ways to do the ‘best possible good’ for the largest population groupings, leaving the lightest ecological footprint. Until we reach that mark, socio-economically, a ‘best practice’ for the greater population, that costs $ are an issue, flushing is the one and only option for them. The general rule for flushing is do so after water has ‘stood’ (not moving) in the piping for more than 6 hours. (The present drought makes this an especially regretful exercise.) For drinking, we hear often “…. let it run for 60 seconds to 2 minutes.” Remember, this is for drinking. There is no need to flush tub and or shower lines for lead concerns. (Legionella is another matter). Morning showers and baths are a good way to flush the main line and branch lines, but the sinks (lav and kitchen) should be flushed as they are daily ‘brought on line’. It is accepted by health professionals that leaving a faucet run for 15 seconds rids the concern (temporarily—6 hours) of built up lead from the faucet/valves own composition. What about copper pipe soldered with leaded solder and flux serving that faucet? How much of your system is/might have been so joined? (It might pay you to do a little investigating.) What the author is trying to do is raise a reader’s understanding that the piping bringing them their drinking water can be more than one type of pipe and has a possible health cost varying between materials used to make it. (There’s a long fought ‘battle’ still going on about health risks of some plastics and drinking water piped through it.) If flushing is our only (present) option, then it would be wise to use established time frames for flushing particular components of the system. Since we are not concerned about the lead issue when bathing, a 5 minute shower with a 2.5 gallon per minute rated shower head draws off close to ten gallons from the system. (Best to perform this significant water use ritual first thing and rid the system of most of its holding capacity. Two 4 minute showers taken simultaneously will go a long way in ridding the system of most of its stored capacity.) The Author confesses he is fixated with how terrible a time it is to be ‘wasting’ water with the West’s drought and at the same time recognizes a needed precaution to protect human health and development. In an attempt to save what water we can and still flush (what we need tool) efficiently, the author wants to share some facts. A lavatory sink faucet with a questionable date (pre 1991) of manufacture (but with a known lead-safe supply) is recommended for a 15 second flush. It would be the same if you drank water from the kitchen sink faucet. A known/estimated length of high lead content (50/50) soldered copper pipe is another kettle of fish. Most faucets are served with ½-inch diameter piping. A 10 foot length of ½-in diameter pipe holds approximately 1 pint of water (1/8 gallon?). A new lavatory faucet in California has an aerator that passes 1.2 gallons per minute (GPM). A new CA approved kitchen sink faucet has an aerator that passes 1.8 GPM. To empty/replace the water in 10 ft. of ½-in. (most common) branch pipe, through an “approved” 1.2 GPM faucet (opened fully) will require approximately 15 seconds. Now if you are running this water to drink (cold…no?) you need only run the cold water. The hot side can be used in other scenarios without wasting it, unused, to drainage. Sister Kettle An uncomfortable fact is that not only lead service lines but galvanized iron/steel water lines are also a source of lead in drinking water. That’s actually b a d news. There are so many miles of the stuff in housing, everywhere, that to remove it would mean in some instances house demolition would be cheaper. The author cringes when contemplating not only the oily mess, but the time it took and the number of oily thread cuttings and dirty rags later, involved in that joining process. But until just recently his “comfort zone” about using the material was over the line in the positive column. Not so anymore. (If it were just threading a water line to the duck blind, for old farts like Pete, I’d give it a pass. But for the General Public I would be happy to see more PEX in its place.) It’s a shame, but “it’s the water, dummy.” Your water quality really dictates which material is best used for the locale. I can remember when after sawing through 90 year old galvanized pipe in old homes in Berkeley, CA and being amazed at what great condition the pipe was in. No build up. No rust. Full wall thickness. In other parts of the State where I’d ‘crank it’ (galv) the terrible local water quality would eat it up in ten years. The initial worry about ‘galv’ was/is the lead content in the zinc coating applied to it (hot, right after its extrusion) to specs: 0.5 (or less) % lead content. Research by Brandi N. Clark, Sheldon Vaughn Masters, and Marc A. Edward of the Environmental Science, Policy and Research Institute found that pipe installed from 1950 to 2008 had lead concentrations from “….non detectable up to 2%.” And a second worry was its success with local water quality. A newer concern is corrosion (‘rust’), Photo 2 & 2a, harboring lead (and at different flow rates ) the Pb could migrate. The corrosion also kills the chlorine added by the Utility/Supplier. Bummer

So, this can present a double loss: Lead Service Line feeding galvanized system which itself could be leaching lead. And then you throw in a little copper pipe (repair/remodel/addition) (50/50 or “lead free”) and you’ve upset the apple cart with galvanic reactions to the mix, ending with even more lead levels in the water. For mixed systems of modern times Pete cannot see a way out of our Pb predicament but to outlive the problem, with the use of filtration and distillation at end-user points. Municipally funded improvements are linked with property decay (and necessary private repair action). The author can visualize water demand/safety issues at some point in the future having the impact that Government 0%-interest loans for end-use filtration/distillation will be as common as those for solar additions. As far as new installation the author sees PEX as the most logical choice. Not only do you ditch the corrosion and the lead threat but also the copper worries. The author dealt with PEX in his revised and expanded edition of Plumbing A House. You will see there, though Pete had his own ideas on ‘terminations’. With the presently available “Press” copper fitting/crimping system (which uses standardized copper tube) and PEX, options to ditch-the-lead in Private Development are here. PEX (no piping) cannot protect you from your private/municipal water utility that flubs up the chemistry, though. It does happen. But PEX d o e s eliminate the lead/copper concerns. (Besides energy and water savings due to efficiency gains.) The Counters Counters (not accountants/bookkeepers). Kitchen counters. Discussion of that topic is often a quagmire for any more than one-person households. The author has had more than his share of EB (embarrassed bystander) moments when discussing (anything to do with) kitchen counters, with clients who were a couple. In this question of whether to employ filtration, distillation or R/O (reverse osmosis), besides costs, c o u n t e r s p a c e and to a lesser degree, under-counter space is going to be a major consideration in choosing purifying appliances. Because the author was once a college grunt assistant to a professor fine tuning s o l a r stills for developing countries, the grunt has a ‘soft spot’ for distillers. Of course they tend to be the bulkiest and biggest challenger for countertop space. Pete the Plumber worked on distillers that looked like something right outta Boris Karloff and/or Vincent Price horror movie sets. But today they are as sleek as high end Italian fashion. No more excuse for embarrassment. The cutting edge countertop filter designs are also available chic. No more excuses there, either. Unless it’s purchase price. But to just attempt a remedy for existing infrastructure’s needs, there’s enough room for a market, and costs will come down. The Reader can see why ‘under counter’ and ‘countertop’ water purification appliances appeal to those who want to save water, opposed to those who choose to “let it run” in the flush mode. For the ‘savers’, after Initial investment it was then peace-of-mind. There are also “whole house” filters (which usually require installation by experts) that are designed to remove lead…and more. As the Western States drought continues we ‘bystanders’ will be experiencing more upon more requests for conserving. Pete believes he’ll also see the return of a ‘bootleg’ specialized under-sink drainage fitting that allows/allowed the user to select where to send the drainage. Down the Sanitary System or…”where waz you think’n?” The laundry. Play Ball The Romans knew not of Ballcocks. Their waste piping ran 24/7. Most citizens were not aware of the dangers of lead. Plates, bowls, and drinking vessels of the time were also made of lead. The author believes he remembers lead “squeeze tube” toothpaste and mendicants of various stripes in his childhood. Lead had a good, long run. But the author doth have another confession: he badly misses his bread loaf-sized brick of solid lead. It was the BEST under surface for the hand punching of many materials, foremost leather; soft plastics; soft sheet metals, paper, and e s p e c I a l l y gasket paper/materials. “Somewhere laid it down… In closing Pete would like to say that he hopes the action taken by the 117th will result in totally lead free Service Lines, for all…even if it does take a while. But it won’t happen if we don’t ‘come together on this’ and play ball. Until Next Time… PtP Coincidence/Hope The author just learned in a Water Online e-mail (www.wateronline.com/doc/newark-completes-lead-service-line-replacement-program-0001) that the City of Newark, New Jersey, has completed its Lead Service Line Replacement Program (LSLRP) replacing 24,000 lead Service Lines in just 3 years, seven years ahead of original schedule, thanks to the 117th legislature’s funding. If ‘Jersey’ can do it, why can’t the rest of us? Pete the Plumber would like to leave the following links to two short articles he believes the General Public would find enjoyably enlightening… Link 1: A Brief History of Lead in Water Supplies The author wanted to call to his readers’ attention this article from Fluence Corporation on the history of lead in drinking water. It is well written and especially geared for the general public. https://www.fluencecorp.com/brief-history-lead-water-supplies/ Link 2: Chlorine vs. Chloramines: What's the Difference? The author has used the names chlorine and chloramines in this article. To the layperson this might create some confusion. The link below is a very good explanation for the learner. https://www.aquasana.com/info/water-treatment-trend-chloramine-in-use-causes-lead-leaching-pd.html

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Author

Peter Hemp is a San Francisco East Bay residential plumber and plumbing author and former R & D steam vehicle plumber. His hobbies are ocean kayaking and touring the Left Coast by bicycle. Archives

September 2021

Categories |

|

|

Copyright © 2017 - 2022

All Rights Reserved

All Rights Reserved

RSS Feed

RSS Feed