|

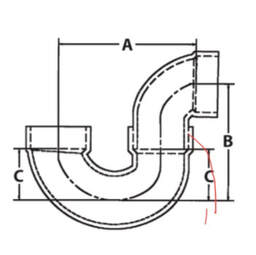

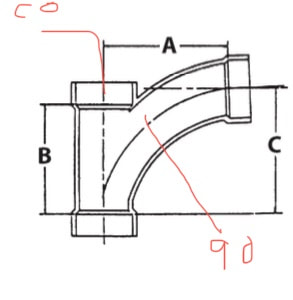

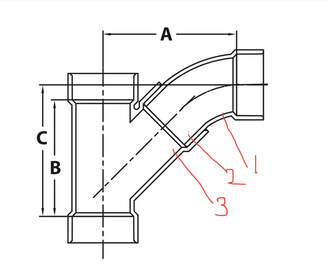

Aloha! Pete just got back to the beach. Hope we didn’t lose any of the crew. Since the last ‘Pipe’ the author voyaged south to meet his mentor Larry Weingarten and the two led a one week hands- on plumbing class, DWV this time being the author’s responsibility. There is n o better way to teach anything than doing it ‘hands on’. Unfortunately not too many are fortunate enough to arrange such a ‘leg up’ opportunity. The author considers himself a proficient instructor when he is demonstrating with real materials on a real structure. Trying to elucidate the same information by word and representational art is another kettle of fish. In this last class, Pete the Plumber was given an hour and-a-half for lecture time and the rest of the week (fortunately) was actually doing-it. The author confesses that he is better at authoring than he is at speaking. Since the subject of Drains, Waste and Vent is such a huge topic, Pete thought it best to do a little second guessing and leave the students a ‘hand-out’ that might hopefully fill in the seams of a leaky lecture. Since this last class was an introduction to DWV, rather than toss his notes over the side at its conclusion, Pete thought they were worth sharing to his ‘In The Pipe’ readers (since he figures most of you are also “wanna learn-ers”). It is the author’s hope that the some of his ‘Pipe’ audience’s ‘foggy logic’ on this confusing and very involved topic might be somewhat clarified by maybe more than one ‘read through’? Are you ready (and willing) to “way-off”? Introduction To: Drains, Waste and Vent (DWV) Definition OF DWV Drains, Waste and Vent is the piping system plumbers create/install to safely convey the liquid and waterborne wastes derived from ordinary living processes to a public sewer or private sewage disposal system (septic). Let me mention that by ordinary living processes the author infers human excrement (urine and stool), and in some cases food waste processed by a ‘garbage disposer’, NOT waste from industrial activity. The UPC (Uniform Plumbing Code) (the code of Pete’s bailiwick) lists Sewage as: “Liquid waste containing animal or vegetable matter in suspension or solution [and that may include liquids containing chemicals in solution.”] My note: (sewer) piping begins 2 feet away from the exterior foundation of the structure. So this means sewers are N O T considered a portion of DWV. Further downstream PtP will “go over with you” the ‘established’ (UPC) definitions. Like dialects in various parts of the Country, the ear will hear more than one word for the same item. It can be confusing for some learners. Plumbers also seem to attract the more superstitious practitioners of all memberships. (Won’t take that further.) So, a fitting, in one part of the Country may have a different spoken vernacular description than in other locales. We need coherency of terms when discussing such a huge topic as that of DWV and its installation. It’s important: we ALL need to be on the ‘same page’ as for descriptions of the materials we will be using. *In some jurisdictions a separate permit process involves the installation of sewers. Even though the sewer “lateral” (pipe) is laid on private property, to within 2 feet of the structure. The lateral is directly connected to the public, main sewer (sometimes referred simply to the main, and therefore of critical interest to the Authority. Therefore private contractors are not allowed to ‘touch’ the ‘City Main’. Municipal workers (or contractors selected by the Local Authority) add the connection to the sewer and bring the new pipe (lateral) onto the building site. (However the c o s t to expose the sewer and add the connection for the lateral is often included in permit fees.) The Big Mystery The ability to design a safe and efficient DWV plan is the ‘Holy Grail’ for plumbers. Water systems function because of pressure. DWV operates on gravity. Think of DWV as a one chance system: You have only once chance that the “waste” you introduce to the DWV, makes it outta the building and into the sewer lateral (or septic). If it stops before exiting the drains and wastes, into the sewer lateral, there is usually no easy fix. You have a clog/stoppage prone dwelling until the design issues are rectified. The author sees a parallel in designing/building a DWV system not totally unlike making a “Pinewood Derby” car. In a race, it has once chance. On water systems, a poorly supplied plumbing fixture can be ‘helped out’ by increasing the pressure at which it is pumped. DWV is a ‘one shot’ proposition. It operates on gravity (a value of 9.8 meters per second, squared.) (14.7 psi.) Like auto parts stores selling “additives” to help unclog your auto cooling system, there’s no ‘additive’ to bump up gravity to help sluggish DWV systems. It’s critical to employ DWV pipe and fittings as would bobsled course designers make the most “fluid” twists and turns of ice course. Matter of fact, it would behoove learners of DWV design, to think (visualize) their potential piping paths (structure allowing) as mini-bobsled runs. Keep up the velocity (speed) of poop/paper/food scraps (occasional goldfish) gliding/sliding at a constant ¼-inch per foot until we say goodbye to them at the sewer entrance. The fewer ‘tight’ (speed robbing) turns created by multiple combinations of DWV fittings, the better. (The author allows that to create superior operating DWV, sometimes he will use more fittings in their design.) What’s What Upstream Pete mentioned Definitions. Now is a good time to go through those. Let’s start with the three initials in DWV. These will be lifted verbatim from the UPC with a possible little ‘English’ for clarity. Drain A pipe that carries waste or waterborne waste in a building drainage system. Waste Liquid Waste: The discharge from a fixture, appliance, or appurtenance in connection with a plumbing system that does not contain fecal matter (bold emphasis mine). Industrial Waste: Liquid or waterborne waste from industrial or commercial processes except domestic sewage. (We will be revisiting this definition) Vent The vertical pipe installed primarily for the purpose of providing circulation of air to and from any part of the drainage system Plumbing Vent A pipe provided to ventilate a plumbing system, to prevent trap siphonage and back pressure, to equalize the air pressure within the drainage system. Individual Vent “A pipe installed to a fixture trap and connects with the vent system above the fixture served; or terminates in the open air.” (Or, a l l b y I t s e l f ! ) Main Vent The primary artery of the venting system to which vent branches may be connected. Venting is/can be a difficult path. It can/has ruled-out many a ‘wet’ floor plan, because of the impossibility of finding a code sanctioned path without structural changes to accommodate. There are books by others on the topic already. The author has ‘cried’ on numerous occasions where a fabulous location for a tub, for a sink, for a toilet, bidet, etc. could not happen, because the structure of the building ruled-out a code sanctioned path for a vent. Poo Time So far, in the Definitions, we’ve seen no pipe expressly mentioning the transport of poop. Until now. That pipe is the Soil Pipe: “A pipe that conveys the discharge of water closets, urinals, clinical sinks, or fixtures having similar functions of collection and removal of domestic sewage, with or without the discharge from other fixtures, to the building drain or building sewer.” (That’s one very important pipe.) It can carry poop. (Night Soil). (Shower drains and Washing Machine drains are considered soil piping because diapers are rinsed/cleaned in them.) Sewage Liquid waste containing animal or vegetable matter in suspension or solution and that may include liquids containing chemicals in solution. The word sewage is another ‘term’ that is often misinterpreted. What the author wants his readers to understand is that his focus in this article: “DWV”, is on piping that sends “...household wastes…” on-their-way to the point of connection (2-ft. from foundation exterior) with their “lateral”. From there, in Pete’s mind, it may be considered sewage. What’s The Secret? The secret to designing a successful DWV system is to know your materials and your ‘code’. The author just finished a helper position on a two-story, two-family, total re-pipe. DWV h a d to be iron or copper. Water h a d to be copper. Former floor plans had been spun ‘this way-and-that’. It was a physical (and organizational) challenge for yours truly. However it was also a great opportunity to have had a “re-fresher” acquaintance with the making of a “hot lead” joint. No longer legal in CA. (The author has been asked/will demonstrate in the up-coming Weingarten Class in August). Materials Yours truly is so old that he remembers when cast iron was the o n l y choice of drainage pipe material and threaded galvanized steel was the sole, alternate, vent material. There were no other choices. Thankfully in subsequent years ABS (Acrylonitrile Butadiene Styrene and PVC (Polly Vinyl Chloride) were developed for use in pipe and fitting materials. A one foot long piece of modern, 4-inch cast iron pipe (CI) weighs over 9 pounds. It comes in 10-ft. lengths. Eat your ‘Cheerios’ this morning? Correspondingly a one foot piece of 4-in ABS or PVC (they weigh closely [for now]) is approximately 1.5 lbs. These come from the manufacturer in 20-ft. lengths but are easily hand-cut to two 10-footers making transport easier. Both ABS pipe and PVC pipe and respective fittings are sanctioned by the UPC. Can you, where you live, use either? Or only one of them? It’s most common to not find both materials sanctioned in any particular district. (It’s the case of manufacturer’s ‘carpet baggers’.) But, there are pro’s and con’s to using each type. If you were to horizontally suspend, by near-ends, a length of each pipe and wait a week, you would see that the PVC has bellied (sagged). PVC will require more support/suspension points than ABS. As for gambling which material to lay in a trench PtP would prefer that ‘saggy’ PVC. Its greater plasticity will resist cracking, longer, buried. But what about more than one floor of several wet-walls? The author, given the choice, would prefer the lighter ABS. *The Alameda (CA) City Schools settled on PVC for the DWV in their High School chemistry lab, because the greater harsh chemical protection PVC provides. Who’s Behind the Curtain? When the author was introduced to ABS pipe and fittings (late 1950’s) the pipe was solid wall. That’s the pipe Pete believes that was in the Arizona ‘test house’ that opened-the-door to its adoption, Nationally. Arizona builder John F. Long built a ‘test’ home using ABS pipe and fittings which had its various drains opened up twenty years later and inspected. The ABS showed no wear. In 1960 the FHA approved ABS for DWV. PVC (in general) did not become ‘practical’ until BF Goodrich chemist Waldo Seman “plasticized” it in 1926. (The author is unaware of the pioneering responsible for it.) PVC pipe and fittings for both pressure (water) and DWV were used on a experimental basis in the 1960’s in Germany in a similar scheme that Arizona builder John F. Long was granted: “Install it and we’ll assess.” In the late 1950’s communities in the U.S. began allowing builders (on a limited basis) using the PVC material with designated downstream ‘inspection protocols’. Today, PVC has its place in the world of DWV pipe and fittings. Matt M. a friend of the authors whose family has operated many wholesale plumbing outlets for many decades told the author that “...if PVC was suddenly allowed for use everywhere ABS was sanctioned, that the ABS manufacturers would be outta business in a week.” Both ABS and PVC DWV fittings are made in the same molds. However (at this writing) Schedule 40 PVC pipe (pressure rated) is the pipe used with PVC DWV fittings to create a PVC DWV System. Contrarily, the ABS pipe used with ABS DWV fittings is not pressure rated like PVC is. ABS pipe is rated: ‘DWV’ (only) and it is restricted for use in gravity operating DWV systems. This non-pressure rated ABS DWV pipe is a “Red Herring.” One reason the ABS DWV pipe is lighter than the Schedule 40 PVC pipe used in PVC DWV systems is because the ABS pipe “has been cheapened” by selling a pipe without a solid wall. (The ABS manufacturers make a lightweight ABS “ foam” sleeve and add a ‘typing paper thick’ layer of solid ABS on the inside bore and on the outside (exterior). The author wonders if his “Great Depression-induced, super economical mother, Mary E., might have had something to do with this.) (Attempt at joke). Anyway, this chicanery came back to bite them. A massive lawsuit for pipe failures. The author will explain what happened, further downstream. According to Water Online, in the US PVC as a piping material has seen significant growth in use in the last 35 years accounting for two-thirds by weight of plastic pipe and almost half of all installed pipe by length in 2004. Joinery There is a basic difference in the assembly time/procedure of PVC versus ABS DWV pipe and fittings. PVC is more resistant to chemicals than ABS. To ‘cement’ PVC pipe and fittings, the plumber first has to treat the pipe end, and inside fitting hub, to a coating of special primer which allows the cement to “sufficiently” grip both surfaces. This is a cement bond. ABS pipe and fittings are actually “welded” by ABS cements. The cements ‘melt’ both joining surfaces. This aspect is what caused the massive lawsuits mentioned upstream involving ABS pipe. Improper (too much) ABS cement can “eat through” the thin, solid layer of ABS pipe in the bore and on the exterior. This places too much shear force on the weak foam core and the weight of pipe runs can shear the pipe loose of fitting, at the joint. *The PVC manufacturers are taking the hint from their ABS competitors and producing a “foam core” PVC DWV pipe. Author’s suggestion: eschew it and stick to the solid Schedule #40 PVC pipe (pressure rated). To make sure plumbers don’t skip using the PVC primer when building PVC systems, the primer is dyed a nice bright purple, which can be detected visually from a distance. This primer used to be sold in a clear solution but too many non-plumber installers (not understanding the the material they were working with), skipped the extra primer application step and PVC systems failed as a result. Among plumbers there can be a certain hesitancy in choosing PVC as their DWV choice (unless they have to) because the extra step of applying the Purple Primer is a messy one (no matter how you try) and ABS is a time saving, cleaner, lighter one-step method. But whose benefit should we be concerned with the most? A plumber’s inconvenience or a better job for the customer? As the author drives/rides in, at, and around domestic development he can’t but wince when he sees the zillion protruding ABS vents on square miles of ever-widening roof-ista’s . That piping (whether ABS or PVC) deteriorates in direct sunlight. (The ABS faster). Where the developments began, Pete could probably (in one dandelion whack), sever one roof protruding vent after the other. These plastics need to be protected with a minimum of a ‘paint job’. Those living with ABS vents (to a lesser degree PVC), a n d the truly concerned, might want to query plumbers about installing vent ‘snow shields’ (covers), which provide 100% sun protection. Cutting the Mustard Whether a plumber installing DWV systems chooses PVC or ABS, if cut by hand, should use a saw with teeth expressly made for the job. The author has tried them all and the PASCO 4333 is still hands down the best for both plastics. However, you will immediately notice that it is more labor intensive to hand cut PVC than ABS. Now Pete has many times over, installed complete DWV systems (mostly ABS) with hand sawing. (Could still do it if forced to.). If a plumber is contemplating more than “just a few cuts” of DWV plastic pipe, he/she would be well rewarded if cuts were performed on a “chop saw”. (With a blade expressly for plastics.) Not only is this operation quicker, but the quality of the cut is so good (with proper blade) that there is no need to ream the inside bore. *All’s it takes is one, tiny splinter of pipe material to stick up, to ruin the flow performance of your horizontal runs, possibly creating a “forever stoppage situation.” However, you s t i l l will want to chamfer the outside edge after cutting of the pipe. This prevents the cement that you are working with from being push entirely out of the hub’s socket and into the pipe, reducing the opening, and as mentioned above, with ABS, could cause a failure. Me No Atlas The author has learned (by association) that students (of the Weingarten Classes) are not likely to be called upon to “design” and install a DWV system, for their present employer (who tends to contract out). But, all of these learners are ‘long-in-the-saddle’ repair tech’s, dealing with the Plumbing/Public’s Inter-face: chivalry meets vandals. Because the topic of DWV is so encompassing, the author thought he should spend the lecture time he was allowed with you, on the most practical (your common involvement) issues that y o u want input on/for. Rather than delve into the arithmetic of pipe sizing (which other than understanding the process/concept, will be of little use in your present work responsibility), in this article Pete wanted to share some recommendations that h e was bequeathed from “Tiny the Plumber”(website/“Me And Angie”); the ‘School Of Hard Knocks’; and tips from other pro’s, that have proved both economical and practical, working with ABS and PVC building DWV systems. (T h e r e is a Transitional Cement to assemble ABS to PVC and vice versa, vetted by manufacturers, but because of the ‘carpet baggers’ the most prevalent application is un-permitted repair work.) No-hub Iron and copper DWV systems both use very similar shaped fittings in their line-up but differ in scale. For variety of fittings the author believes ABS holds the cards, in his Western Region. Go East and it gets more PVC. Working for clients where it’s the plumber’s choice (cannot divulge that Shangri-La) is the most satisfying. Sweep ‘it out’ Over the years the author couldn’t but help learn what he (intrinsically sensed) and what training and experience has reinforced: the best ‘jewel’ in the DWV crown is the magic word: sweep. A small (1/2-inch or, ¾-inch) water supply 90’ has a radius not much more than one of your knuckles. Pete see’s them as quite cavalier about their trimness. They need not be engineered to any reasonable efficiency to meet their expected performance. Why? They have an ace-in-the-hole: app. 60-80 psi doing all the hard work getting their master to where he/she needs to go. DWV, on the other hand is still relying on what Aristotle, Galileo, and later Einstein could see/sense: gravity. No tight bends here. Pure knowledge. Paid for by “learning-on-the-job” plumbers of antiquity dealing with graviton. Were plumbers of antiquity (POA’s) beheaded if their plumbing for the King’s spa backed-up? Maybe it was safer to be a tailor or sailor. Anyhow, the author thinks it’s time we get into the nitty-gritty of the “Introduction of DWV Design” It’s also a good time we each take a bite outta Alice’s magic mushroom. We want small. PtP has found that visualizing he’s in a new whitewater ‘play’ boat (Jackson) and instead of lining a waterfall, he is about to squirt into the overflow ‘tube’ of a large, hydroelectric dam. (Always wondered how many ‘fittings’ that route took to daylight, again.) By visualizing yourself as a kayaker, in a big (for the claustrophobic = c l e a r tube), following the path of your houses DWV, you’d know instinctively how you’d ‘like’ to take those turns and drops. There’s not enough (yet) code sanctioned change-of-direction fittings, available (due to no demand) to mimic the kayak run. (Or a bobsled run). But if just subconsciously, one could be affected to the point that his/her runs became much more ‘efficient’ than ‘code’: progress made. We must remember that ‘Code’ was/is a minimum standard. But of course. When the dollar is involved, few go outta their way to do more than ‘what’s code’. That’s O.K. There are venues for the Cult of Craft (any tradesperson with pride in their work) to keep alive and even boost interest in their methodologies. Upswept Just a few drainage fittings get most “un-initiated” installers into trouble building DWV systems. They are: the 1, the Sanitary Tee, and 2, the Wye. These (aside from another ‘special’ (90’) are up for discussion, first). Sanitary Tees (San Tee) and Wyes are No.’s 1 & 2 (especially to the untrained EYE) because of their “look alike’ ness. The author wagers improper use of these two fittings might be the most common violation. Something I’ve tried with dubious affect is to tell the layperson: “For drainage there is only one (legal) application for the (San Tee) fitting. It’s for receiving trap arms from sinks, showers, toilets and specialized water discharging equipment. No worry. If you’re in a crawl space installing/connecting horizontal drains, you know this fitting is not mean for a n y purpose, under there, with you. Most will encounter it (magic glasses allow you to see inside walls) under their sinks (all) under their tubs, under the shower and near their toilet. All will be in the vertical position (drain at bottom; branch=center; vent=top) as shown in (Photo 1). Where we do not want to find one is connecting drains, especially o n t h e h o r i z o n t a l. The “Weir” Wolf The weir in the branch of the San tee (Photo 1) is so designed (by really smart people) to not let (under ‘normal’ circumstances) liquid waste flowing into it to reach a velocity that would siphon the water out of a trap it was serving. If you replaced that San tee with a Wye (Photo 2) the 45 degree down slope of the Wye branch could generate sufficient velocity to suck the trap ‘dry’. Then gases in the sewer (or septic) could infiltrate your structure. *When Utility gas companies vetted residential open-flame interior lighting in the 1820’-30’s, dry (or non existent) traps caused an unknown percentage of home explosion and fires. It was always (at first) assumed that it was the gas company’s fault. Finally some smarter-than-the-rest person figured it out: There are gases in the ‘drains’ that need to be kept out of the living space. P-traps (Photos 3 & 3a), S-traps, Running-traps, and Barrel-traps were soon included in building codes. The author (usually here, or near) on “Builder’s Breakfast” tells a tale of his favorite barber shop blowing up because of a sewer gas/space heater catastrophe. Fortunately it happened in the middle of the night with no human injuries (or worse). Pete actually sat in the chair that he knew (after the tragedy) was the center of ignition. He even wondered (for years as he was getting his hair cut) if the walnut sized hole in the exposed MBD (Main Building Drain), which ran with its top radius exposed in the slab floor right behind the chair he sat in, would ever cause trouble. The author surmised that a drain cleaning technician had made the hole long ago to insert his cable into the line. So folks, it can, it d o e s happen. The gases commonly found in sanitary drainage systems include: Hydrogen sulfide; methane; esters; carbon monoxide; sulphur dioxide and nitrogen oxide. Four of them burn profusely. These same gases when they are not ignited, can and also cause asphyxiation. The Mine Field As the class is constantly reminded the DWV plumbing system operates on gravity. Because we are straddled with such a “low pressure” force to move our plumbing wastes in whatever our DWV design happens to incorporate, change of direction fittings that we employ to build systems with have to be accurately designed and properly installed. Let’s read what the Uniform Plumbing Code has to say in their introduction to this topic: “Changes-in-direction of drainage piping shall be made by the appropriate use of approved fittings, and shall be of angles presented by a:

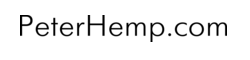

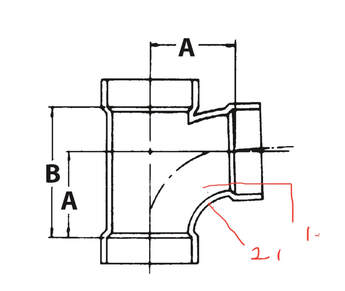

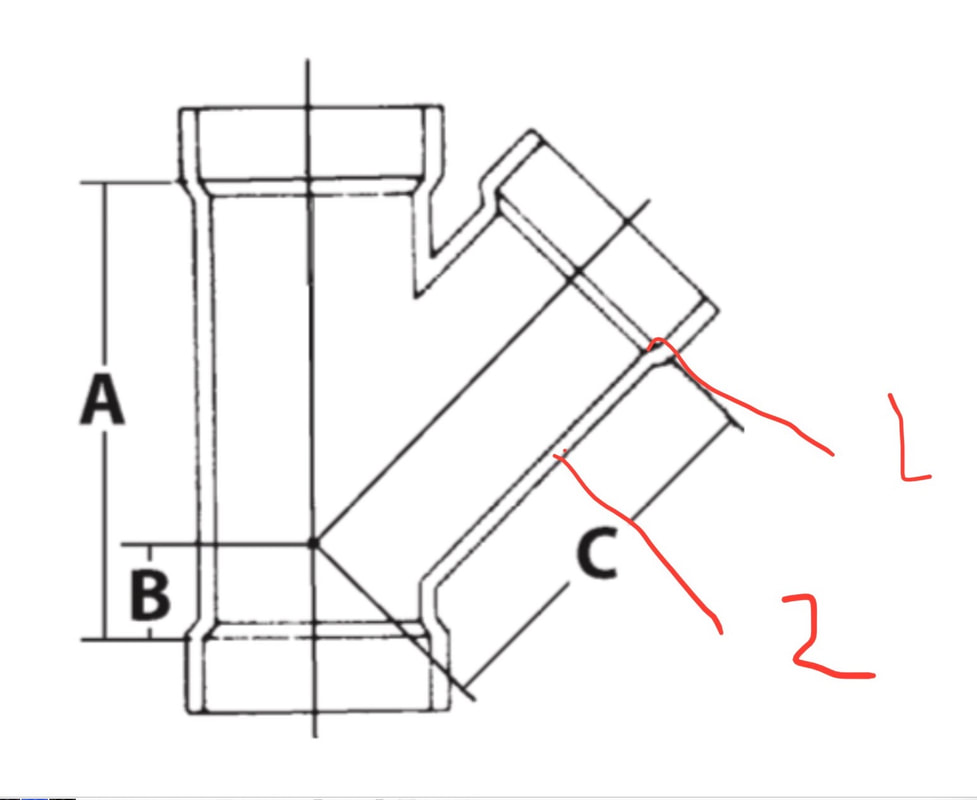

Note: We did not see ¼ bends (90’s) in this listing. Does that mean we cannot have a horizontal 90’ in our design? The answer is NO. We can by using a “special” 90 (noted upstream) that incorporates a clean out extension provision (Photo 4) to building perimeter that is time consuming to install in most instances so we try to not have to employ one, to begin with. We see mentioned in: Edict 706.2 “Horizontal drain lines connecting with a vertical stack shall enter through (Photo 2) 45 degree Wye branches...(A stack is: “The vertical main pipe of a system of soil, waste, or vent piping extending through one or more stories.”) Edict 706.3 “Horizontal drainage lines connecting with other horizontal drainage lines shall either through 45 degree Wye branches, combination Wye and 1/8th bend branches (Photo 5) or other ‘approved’ fittings of equivalent sweep.” Edict 706.4 “Vertical drainage lines connecting with horizontal drainage lines shall enter through 45’ Wye branches or other approved fittings of equivalent sweep.” Edict 707.4 “Each horizontal drainage pipe shall be provided with a clean-out (CO) at its upper terminal, and each run of piping that is more than 100 feet in total developed length shall be provided a clean out for each 100 feet or fraction thereof. An additional clean out shall be provided in a drainage line for each aggregate horizontal change of direction exceeding 135 degrees…” (That’s one ‘90’ elbow and one 45 degree elbow…or…three 45’s…or six 1/16th bends (22&1/2 degrees) or…mix and match. I Didn’t Say That… Pete the plumber now wants to touch upon the most common code “misunderstandings” where most violations by the uninitiated occur. These boo-boo’s are concentrated in the Edicts designated 706.0: Changes In Direction and Flow, in the Uniform Code, beginning with Edict 706.1 and Vents 901.2 through 908.1

*Now there is a Get Out Of Jail card for this edict, 708.1. If you happen to be running a minimum pipe diameter of 4-inch, the UPC says this: “…where this (1/4-in. per ft.) is impractical due to the depth of the street sewer, to the structural features, or to the arrangement of a building…pipe or piping 4 inches or larger in diameter shall be permitted to have a slope of not less than 1/8-in. per ft. where first approved by the Authority Having Jurisdiction.” For any size pipe under 4 inch you’re out of luck. This can be a good reason to install a 4-inch Building Drain and lateral for a problematically sited home in relation to sewer depth, even when 3-inch would satisfy serving the fixture units of the design. Onward…

Because most class members will not be tasked with designing a new DWV system during their maintenance career, the author wanted to concentrate on the area where they are already functioning: maintenance and repair of their existing DWV systems. Traditionally, the class (broken into teams of usually five members) will be tasked with designing and installing a mock-up DWV system for a theoretical ADA bathroom, on premises, that includes water supply and gas line to a water heater. The author looks forward to closely working with each team to make sure they fully understand the principals involved with their completed DWV system. Off To The Pub Pete hopes this Intro to DWV which he wrote for one of his classes proved of interest to his readers of In The Pipe. If the author has accomplished nothing more than to show the reader that properly designed and installed DWV systems are an art form, he’d consider it worth the time of writing. Until Next Time Pete the Plumber

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

Author

Peter Hemp is a San Francisco East Bay residential plumber and plumbing author and former R & D steam vehicle plumber. His hobbies are ocean kayaking and touring the Left Coast by bicycle. Archives

September 2021

Categories |

|

|

Copyright © 2017 - 2022

All Rights Reserved

All Rights Reserved

RSS Feed

RSS Feed