|

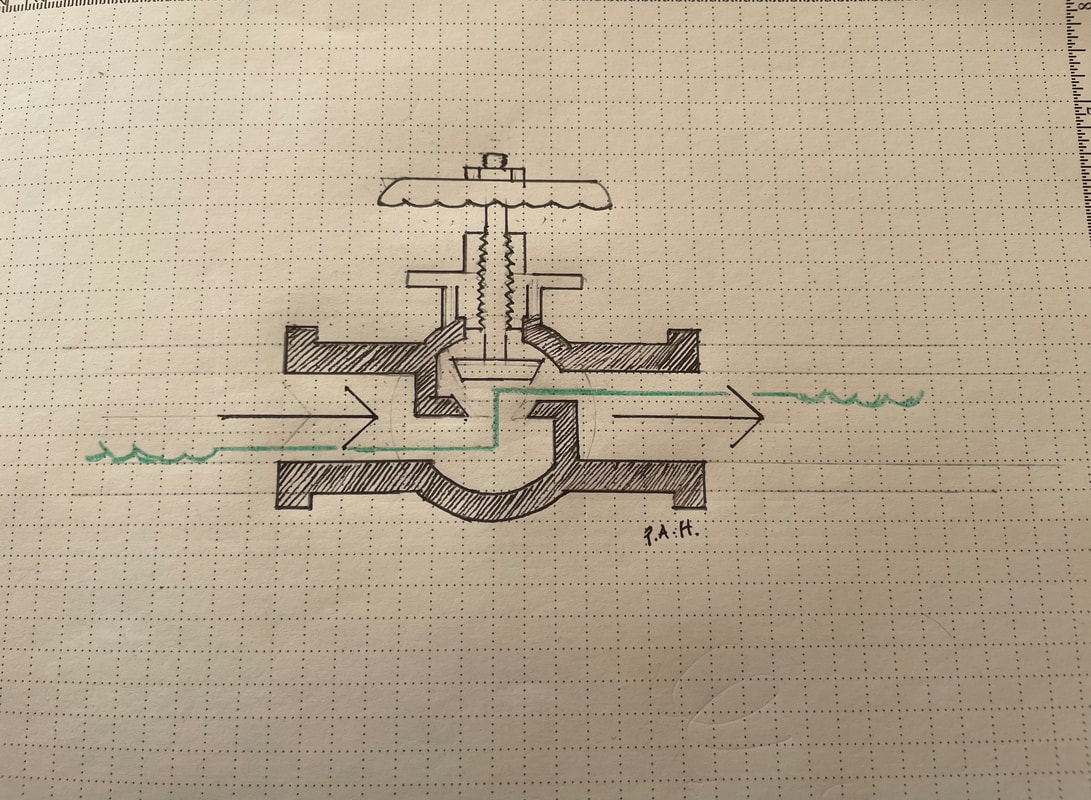

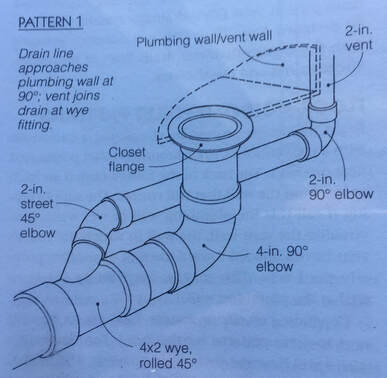

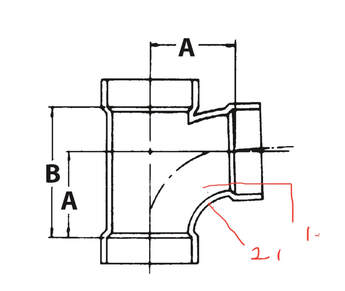

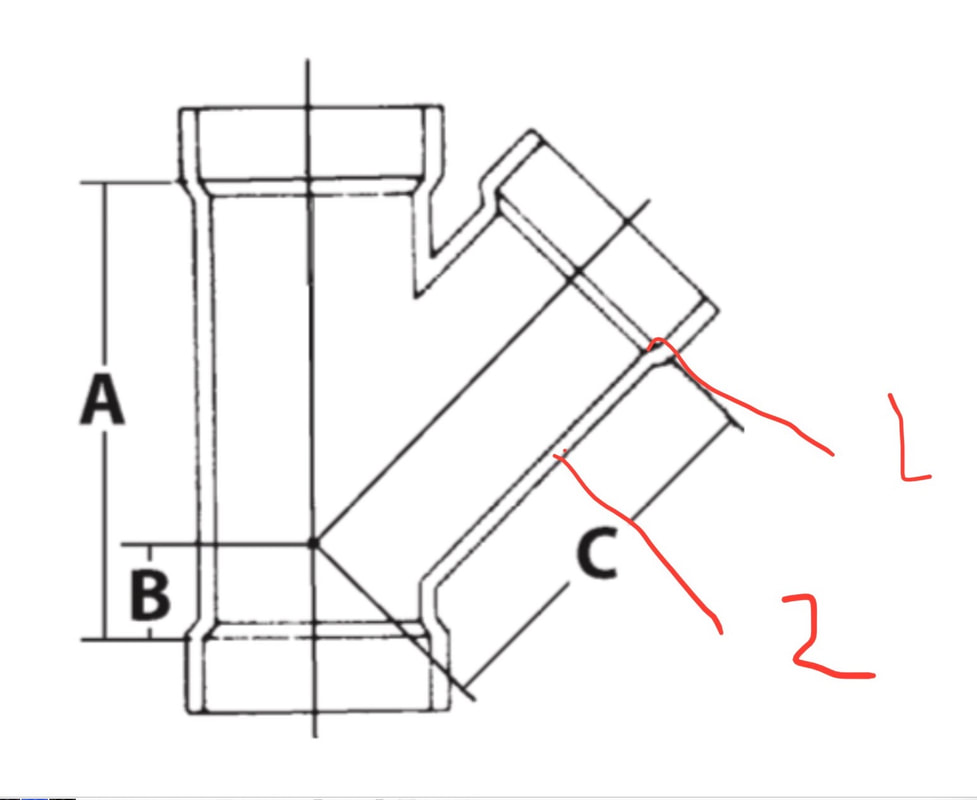

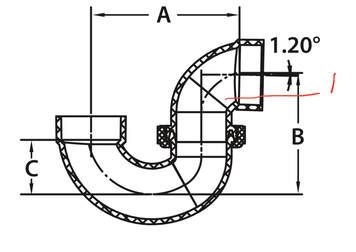

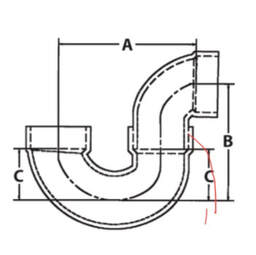

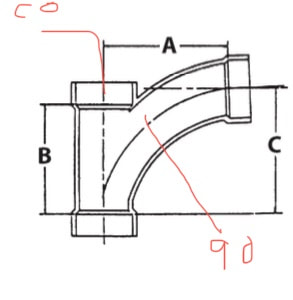

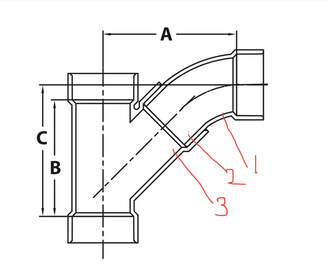

Greetings one and all. Pete the Plumber has been very busy of late, not however with anything to do with plumbing. His missing Pipe action was due to an ‘outta left field’ influence: for the first time in his life, he fell prey to an unexpected (but common to many others) impulse. He planted a vegetable and flower garden. (Photos 1a & 1b.) And being a ‘greenhorn’ in such endeavors he foolishly went a bit overboard. (Homer, his long-deceased Wisconsin farmer grandfather would most certainly find this spectacle hilarious.) A bit like ‘gold fever’ the author succumbed to the ‘gardener’s mania’: he left his MasterCard on file at the nursery. (You can just imagine what folly would be possible via such ‘short’ sightedness.) (Oh, but what fun!) (When discounting the sunburn and aching muscles). As of this writing Pete has only one melon trellis to build before he dives (fully) into this next In the Pipe: M.I.A. In Pete’s last Pipe he had a few things to say about helping with the installation of a commercial kitchen for the fledging food Co-Op in his village. During that effort it was necessary to deal with a ‘problem’ which used to be a chronic bone of contention for old time plumbers, long past. True to The Pipe, this ‘bone’ involved both materials and practices. Because in today’s world the majority of freshwater plumbing systems are either plastic (PEX, CPV and a few exotics) and copper, what Pete is going to share in this PIPE will benefit repair plumbers, mostly. The reason for discussing such a ‘limited interest’ topic is because there are still millions of plumbers around the country who ‘now and then’ will want to shake my hand for learning what this article did/does for them. Iron/Steel and Rust Pete ‘cut his chops’ when plumbers were still ‘cranking’ (threading) galvanized steel and galvanized iron pipe for fresh water supply. In many older cities these fruits of plumbers’ labors are still on the job, still supplying life supporting fresh water to millions. In the previous Pipe article the author mentioned working on the NSF (commercial) kitchen, and this endeavor required the use of one of Pete’s specialty plumbers’ tools. A tool that in today’s plastic and copper FWD (Fresh Water Distribution) practice is rarely required. In old metropolitan areas with lots of galvanized pipe still on the job the tool Pete is going to tell you about remains a must have. Will the reader of this Pipe ever need to work with this tool? Hopefully not. My CO-OP assistant for the kitchen plumbing, Ryan, had scored two commercial kitchen faucets, used, on-line. They were ‘workable’ Fisher Company wall-hung models. One of the faucets had broken and corroded galvanized nipples in the supply fittings. NO room for a pipe wrench to grip anything. How were we to get rid of these corroded and broken nipples? The faucet (regardless of its good condition) would be useless unless the supply ports were clean ½ in. F.I.P. (female iron pipe) threads. To rid ourselves of the broken nipples required the use of a Pipe Nipple Extractor (‘back-out’). A LITTLE HISTORY (It won’t hurt you) Back in the 1930’s and until the 50’s most kitchen sink faucets were “Wall-Hung”. Deck sink/counter mounted varieties were yet, years away. An experienced framing carpenter (if not the plumber) in that time framed two, (in those days, ‘rough’) studs: 9.0” to 10.0” ‘inside to inside’, at a point on the wet wall that centered on the sink. (Illus. 1.) The ‘hot’ and ‘cold’ galvanized pipe (risers) supplying the kitchen sink faucet were fastened to the insides of the studs with “spikes” (considerably bigger than standard #16 penny for framing.) The fastening consisted of “bending over” the spikes on the piping. There might be 6 or more spikes used on each pipe, to hold it firmly on (or very close to) 8 inch ‘on centers. What’s the 8 inch on center for? The reason is the pipe connections of the wall-hung kitchen sink faucet was/still is 8-in. on center. Post Tile On the top of the galvanized “risers”, before spiking, 90-degree change of direction fittings were installed, port facing out. (See Illus. 1 above.) These ‘90’s’ were behind (inside) the ‘finish wall’. The’ finish’ of the finish wall might be tile or stone for the financially able or Marmoleum/linoleum for the proletariat. Regardless, galvanized steel nipples (of several possible lengths) needed to be threaded into those ‘in the wall’ spiked 90’s after ‘finish’ wall was completed. The length of these nipples depended upon how deep in the wall the plumber spiked the risers and the thickness of the ‘finish’: mortar bed and tile (2-in.?) versus linoleum (1/8-in.?) (or as part of a wall hung cast iron sink ‘backsplash’ (2-in.?) * If brass nipples were used in place of galvanized ones, and their lengths were under 6-inches long, the corrosion that occurs at the brass nipple and galvanized 90’ is more difficult to deal with than corroded nipples at the faucet connections, with steel nipples. Corrosion deeper inside the wall at the riser 90’ makes the extraction/repair a much more difficult operation and much more $$$$$$ (rather than shorter nipples near the finish wall surface. * Brass nipples 6 inches long (or longer) may join steel components with less dielectric caused corrosion than the practically useless dielectric unions sold to plumbers today. * 8-in. wall-hung kitchen sink faucets (fortunately) include off-set adapters which allow the plumber to install the faucet to nipples not on a perfect 8-in. on center. (Few were). With Time Once the wall-hung sink faucet was set on the finish wall, years to decades (occasionally) a generation later, galvanized nipples holding the faucet in place commonly begin to leak and need replacement. The speeds at how quickly the corrosion occurs also depends upon the quality (purity) of the water supply. Without a specialized tool to accomplish this nipple removal, the job cannot be done without opening the wall (unless you are a dentist, with all your tools at home). There are a number of manufacturers making various designs of ‘specialized’ tools (pipe nipple extractors) (‘back-outs) for this task. The author has found one particular design, by one particular manufacturer to have never ‘let him down’. He’s tried almost all of the others, with mixed results. In this Pipe, the author reveals his ‘tried and proven’ choice/method for removing broken or leaking galvanized ‘in the wall’ nipples. As mentioned, the inspiration for this Pipe topic was born when Pete, during his recent NSF kitchen work, had to dig out his nipple extractor to remove broken nipples from a used, commercial wall hung sink faucet the owners wanted installed. Pete’s helper, Ryan, had never seen one before. It made quick work of the problem. At that moment, this Pipe’s direction catalyzed: introduce readers to the ACE E-X7 (for ½-in. pipe) nipple extractor. (Photo 2.) As the author mentioned upstream it’s predominantly repair plumbers who might best benefit from this post, but there may prove the existence of just “unlucky” home repair activated homeowners sometime faced with extracting a broken galvanized steel nipple for a wall hung faucet, F.I.P. hose bib, F.I.P. washing machine bibs, kitchen/bathroom sink F.I.P. angle stops, and maybe even pumps and other equipment/devices. So, learning about Pete’s choice/favorite pipe nipple extractor, now, will save any of you needing one, the years and anguish Pete paid to ‘figure it out”. On the kitchen job (thanks to the Ex-7) the faucet got mounted on the NSF sink’s stainless-steel backsplash to serve another decade or more. The Line Up Photo’s 3, 3a, 3b and 3c are the most popular, common choices for pipe nipple extractors available today. Some are tapered and square sided, some are tapered spirals, some are almost round with straight ridges and others use a cam action. Pete’s favorite uses tapered spiral gripping ridges in its design. It’s the spiral ridges (at the rate of climb and the overall taper) of his favored tool that’s the ‘magic’ of this tool’s successful performance. You may find other makes of spiral design extractors with similar characteristics, but the author (after all these years) isn’t salivating to experiment. He’s found it! with the Ace EX-7. It resembles the long used broken screw/stud extractor mechanics employ. (The first screw-stud ‘back-out’ the author (at 17) had to use was to remove a broken stud (motor) on his Model A Ford. What’s In a Name The EX-7 means: ‘Number 7 Extractor’, sized to fit ½-in. iron/steel pipe. No.7 is one of several standard sizes in the industry for use with ½-in. pipe. As the pipe diameter increases so does the size of the extractors and its corresponding number designation. For example an EX-9 would be used for ¾-in. pipe and a Number 11 would serve 1-in. pipe. Using the Tool All ‘back-out’s’ (extractors) operate the same way: insert the pointed (or tapered) end of the tool into the nipple (may require a gentle ball-peen (hammer) ‘tap’; and, then a large Crescent wrench is applied to the wrench ‘flats’ (Photo 4) on the ‘fat end’ of the tool. With both hands rotate the wrench (and tool) in a counterclockwise direction. Sometimes Pete has to lean hard against the wrench while using it. As for kitchen wall-hung faucets (and maybe laundry F.I.P. bibs) the plumber remains standing while doing battle. This not the case for F.I.P. angle stops at approximately 16-inches off the floor in bathrooms under a wall-hung lavatory sink or cabinet supported bathroom sink or a kitchen cabinet deck- mounted sink faucet. When someone finds themselves needing to replace broken/leaking nipples in a situation where the labor cannot be accomplished while standing, the chore becomes much more distasteful. For an F.I.P. angle stop serving a toilet or bidet, the job may require lifting the fixtures to gain sufficient “tussle room”. The ACE-EX 7 works wonderfully for extracting nipples that happen to be as long (or longer) than the tool itself. When the situation though involves a short (‘close’): 1-in. long or 1 & ½-in. long nipple threaded into a 90 or 45 degree fitting, sometimes the tip of the tool strikes the inside radius of the fitting before the ‘gripping’ ridges can engage (effectively) the inside walls of the nipple allowing it to be “un-screwed”. (Illus. 2.) Pete solved this problem. With a diamond ‘cut-off’ disk on his grinder he shortened another EX-7 for those occasions when the standard EX-7 is too long. (Photo 5.) A manufacturer of plumbing tools, PASCO, has come to the same conclusion and offers a ‘shortened’ version of a # 7 spiral extractor (Photo 6). Wrenching Thought The author’s first choice of wrench to use with the #7 extractor is a 12-in. Crescent wrench. If it’s a “no budge” attempt, he gets his 15-in. out for the job. This operation does have a ‘worry aspect’ about it. On very old piping Pete has broken piping inside the wall trying to extract stubborn nipples. Depending upon the circumstances the degree of damage varies. If Pete broke piping for a wall hung sink, on tile, we now (unfortunately) have a need for a tile setter to repair the finish when the plumbing work is completed. When breakage occurs behind ‘drywall’ or plaster it’s still unfortunate but usually within the ability of the author to repair. Under Cabinets Attempting to extract galvanized nipples under sink cabinets, using adjustable wrenches is almost always a futile effort because of restricted working space. (Pete the Plumber absolutely hates/despises two-door cabinets with a center divider.) It is sometimes necessary to remove from the wall a small bathroom sink cabinet to achieve working room. It required a ‘gestation’ period but Pete came up with a method to remove nipples when they happened to be under a sink cabinet. The author happened to have a good collection of mechanics’ tools (to keep his trucks running) and one day, when needing to replace nipples but challenged by a kitchen sink cabinet, the lightbulb went on: ‘breaker bar’, three ½-in. socket extensions, and a 12-point socket to fit the ‘flat’ (butt) end of the ‘back-out”. Instead of the usual 6-point mechanics’ sockets used on hexagonal (SAE) nuts and bolts, a 12-point socket (Photo 7) fits a square nut and the square end of the ACE E-X7! With a few long socket extensions, a 12-point socket to host his extractor, and breaker bar, Pete could remain kneeling, outside of the cabinet and remove those pesky/leaking nipples. Whew! * Not all squared wrench flats of the various manufacturers’ ’back-outs’ are able to use a same-sized 12-point socket because of un-uniformity in quality control efforts. The author has found it might be necessary to have two sockets if you are not using an Ace EX-7 due to the sometimes-larger dimensioned competitor’s extractors/back-outs. (Photo 8.) That’s about ‘it’ for this topic for now. Gotta get my watering done this morning before the expected 106 degrees arrives around noon. Aphids anyone? Hopefully you, the reader (unless you are a plumber) never have to replace any leaking galvanized nipples using extractors, of any design/make. (Or have to go purchase the extra tools mentioned in order to perform the work.) But/however you may, someday, be able to enlighten an unfortunate individual who is faced with this very need. Next Time PtP

0 Comments