|

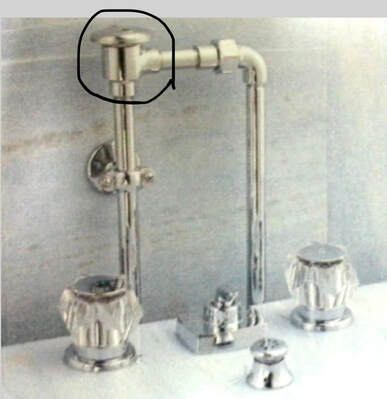

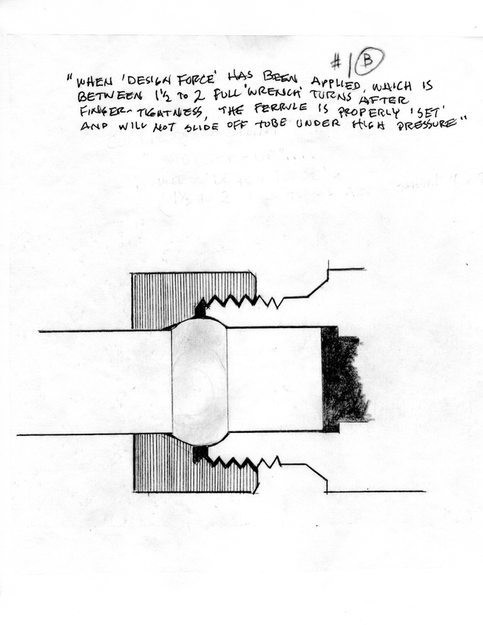

Hello Readers of ‘The Pipe’, It’s that time again. Another volley of personal perspective. As we here in North America are about to enter another summer (and growing season) it’s evident we do so (in some regions) with frighteningly low levels of stored water, both in the ground and in lakes and reservoirs. The author has been reading that in the middle and western states this summer and fall, severe water use restrictions can be expected, as a result. (PtP can recall the 1970-‘77 California drought where at the worst stage, residents of the City of San Rafael received as much as a $50.00 fine for as little as one too many toilet flushes.) And, how many readers remember “The yellow’s mellow but the brown goes down”, or “Share the water, shower with your neighbors”? Well, now PtP believes it’s very possible a sizable number of us Sunbelters are, in the near future, going to revisit some of these strapped conditions. Yes, it’s scary, in more ways than one. (The author lives deep in an already stressed fire-prone forest.) How bad can it get? Only time will tell. But in this blogpost the author will revisit some of the standard water saving precautions we tend to forget or overlook in plentiful water times but may now, again, be worth paying attention to. The Whales There are four consistent trouble makers when it comes to the most common causes for water waste involving residences. Pete likes to think of them as The Four Whales. This post will not be a repair tutorial but rather a maintenance preparedness reference for a possible Western/Mid-Western mega-drought. 1st Whale: Thirsty Mechanical Servants Pete the Plumber’s long time good friend, Berkeley professor C. McGee, once had a fridge/freezer that should have been retired a generation previous to its demise, but the old Scot just couldn’t bring himself to chuck it and buy a new one. This went on for years until finally he was finding his chilling martini glasses totally entombed in ice. After PtP’s constant chiding (and ice chipping) the Perfesser relented and replaced the old servant with an efficient new refrigerator/freezer. (He learned from the appliance store that his old fridge/freezer had six motors which when new, the electricity to run them was cheap.) (The ‘Perfesser’s’ electricity (aside his drinking water) was also sourced from hydro-power, hundreds of miles away, part of the biggest plumbing system on the planet. It was the same with his automatic washing machine. I think Eisenhower was President when it was made. A rivulet of water ran out from under it every time it ran. Conveniently a floor drain was feet away. When the rivulet eventually became a horse piss the old Scot’s disdain to spend was drowned into action. A a new mechanical servant was installed. (After a rather short interim (two utility’s billing cycles) later the Perfesser was bragging that between the savings over the old fridge/freezers electric bills and the water and power savings over his old washing machine, he was ‘ahead’ twenty-five dollars a month. So, (the lesson) if you have been thinking (dreaming) of replacing some long serving water and/or power hungry appliance (fridge/freezer, dishwasher, or washing machine), according to meteorological science reports it appears there would be no better time than now to do it. *Also, if your dwelling is served by a water utility, you should check with them for any number of money saving incentives they may have on offer. Pete the Plumber has saved many of his clients considerable sums by recommending that action. If ‘things’ (drought effects) do get really ‘dicey’ again, fees are going to climb sharply to possibly astronomical. Any such incentive programs acted upon will have proved prescient. Don’t lose out. Timing and the 2nd Whale: Bathing Just as the public has been informed through community service media that we can save on our electric bill by timing our washing machine and dishwasher use to ‘off’ hours, time and water play another part in our rhythmical hygienic habit: bathing. Be honest now. Who hasn’t fallen back into long showers and/or deep soaks since the last time we were asked to drastically reduce our water usage? The time it takes automatic appliances to go through their various cycles, is, automatically programmed. Even though our present, possible decadent bathing practice (2nd Whale) may seem ‘automatic’ to us, we are the programmer. We may discover here in the future just how much monetary expense we will endure to enjoy our presently unregulated bathing habit. At the State Park we may insert several dollars of quarters in the slot to take a hot shower of the shortest ‘acceptable’ duration. In a worse case scenario we could see comparable pricing (or worse) at home, on our monthly utility statement. A Suggestion May the author make a suggestion? (Too bad if you disagree). ‘Things’ can have a way of becoming pretty irritating to us in our daily activities, but one thing that is almost universal: a good hot bath or hot shower goes a long way reversing it. Though yours truly wasn’t in the military service (Boy Scouts doesn’t quite cut it) he wishes to mention/introduce a military term: G.I. Shower. You have probably heard the term and already understand the concept. (But PtP doesn’t want to lose any stragglers.) The G.I. Shower equates to a: quick, military version of a low water use bathing method, via a timing. This method means shower water running in short segments, with it turned off in between, while the bather lathers. Then the water is resumed to rinse down the body. This timing cycle: water on/water off (in military scenarios) serves two purposes. One, is to reinforce the concept of efficient use of ‘supplies’, and the military’s other intent (of course) is torture: to ‘viscerally’ remind the bather who’s the boss. Doing It PtP wants to tell you in the next paragraph about a little piece of plumbing hardware (which has been around for decades) that can remove any semblance of torture for conscientious civilians (sand crabs?) wanting/needing to take ‘action’ to combat the ‘tyranny’ of severe water restrictions, which could interfere with their personal desires involving the cleaning and maintenance of their bodies. Mounting the Flow With the incorporation of a flow control valve (Photo 1) on your shower arm, upstream of the shower head, lucky civilians can learn to enjoy an actual civilized version of the G.I. shower (with the superior to G.I. bath fittings in most homes). This routine will come in handy when ‘things’ get ‘dicey’. Because of the flow control valves ability to abruptly stop and then let go of a pre-determined temperature and volume of water, there’s a huge savings by two measures. Read on to find out how and why. Most tub and shower valves manufactured at this writing are now single handle designs. The reason for this is scald safety. The long used two handle shower valve was cause for many tragic burns, usually involving children’s use of the plumbing and to a lesser degree tragic burns to adults from using an unfamiliar shower valve which was improperly installed (hot and cold piping were switched.) States like California (usually first at everything) finally put their foot down and mandated no more unregulated two handle and single handle shower valves. After a certain date a l l shower valves sold in the State had to be temperature compensated so that a bather, by his/her actions or due to a negligent plumber could not scald themselves when using the shower. A two handle shower valve can be temperature regulated by plumbing in an additional temperature control device. The added cost of the extra device and the plumber’s labor time to install it makes this an unappealing choice for most consumers. Manufacturers found the simplest fix was to modify a single handle valve to attain the goal of scald-safe. The internal mechanics of a scald safe valve means (except for one version mentioned downstream) the valve first begins sending only cold water. The hot water is added as the flow is increased, awaiting “The Three Bears” ‘just right’ point. As you go from cold to the hot in the “just right” direction, the flow also increases. Many bathers using single handle scald safe shower valves (without the addition of a flow control valve) never find the “just right” combination of flow rate and temperature that they most desire.) See: Slight Detour, downstream. With scald safe valves there is no way anyone can make hot come out first (like one could do with the ‘old style’ two or ‘old style’ unregulated single handle valve). An ability to turn on the hot water first is what caused so many scalds over the years. ‘High end’ models of some scald safe tub/shower valves are offered in a pre-temp version where the bather selects the desired temperature prior to turning on the valve. The price there-of is reflective. The ‘G.I.’ Made Easy And Mostly Painless Having to re-adjust both temperature and flow rate each time one turned off a two-handle shower valve in order to conserve water, and perform a ‘G.I.’, the author believes was an imposing force of resistance to doing the routine. But, with the inclusion of the flow control valve on the shower arm, it’s an all new ballgame. With a flow control valve (Photo 1, above) on the shower arm, we have the luxury of maintaining the temperature and flow the bather first selected, and, return immediately the same with each ‘on-and-off’. This allows (with a quality shower head) for a surprisingly degree of ‘pleasant enough acceptance’ for a more water saving bathing routine if and when it becomes mandatory. A Slight Detour The author lives in an apartment blessed with a spacious bathroom and spacious shower with a non-pre-select temp, scald-safe single handle shower valve. Because PtP likes things hot, to attain his desired temperature for a shower the valve will also have to be operating at near full volume. Now you might find this a bit odd but Pete prefers his hot water delivered from his shower head at a somewhat reduced (wimpy?) flow rate. Without the added flow control valve Pete would be out of luck. To get his desired temp he would have no control over how much force the valve produced. The flow control valve lets the scald safe valve operate normally to attain desired temperature and at the same time also lets the bather select the flow rate of that “just right” shower water. Not only that, but by leaving the knob on the flow control valve where he found his “just right”, he saves water with each shower by not having to “search” for his/her “just right” with the water running (with or without the neighbors). Confession The author admits that he likes nothing better than lying in his antique, 6’, legged cast iron tub, out on his deck (up to his chin) in 104 degree heaven, on a starry night, soaking with Ms.Piggy Bubble Bath in water that’s derived from his free-flow spring— for free. 3rd Whale Our first whale of a cause for high bills of water and energy, just discussed upstream, was out dated washing machines. Our Second Whale was bathing (our choice of shower habits). Our third whale cause for high usage and high bills is our toilets. A running toilet can easily go through 30,000 or more gallons of water a week. If things were to get drought ‘dicey’, at those volumes, someone’s most basic bodily function might have to function in a less than convenient place. (As a touring cyclist PtP learned first hand what a convenience a BM was on a manufactured fixture in a private setting.) Toilets tend to leak large volumes of water in two places. Either the fill valve (Photos 2 & 2a) does not shut fully off and the tank over fills, and the excess flow, through a connected poly Fill Tube, goes over to and down the Flush valve’s Over-flow Tube (Photos 3, 3a & 3b), sending potentially thousands of gallons of fresh, drinking water, very slowly and silently down the MBD (Main Building Drain). The cost of that wasted (and soon to be precious) water at severe drought pricing would be prohibitive. The second common water loss is a leak at the tank flush valve (Photo 4). At the time PtP first buckled on his tool belt there were several unique designs of flush valves commonly found in his district. Today, what’s called generically a flapper design (Photo 4 ) is industry-wide, the most common. Because of its shape, plumbers often referred to them as pancakes (Photo 4a). Over the years, other competing designs found some favor, one of them the tilt-back.

Tilt-Back One of the major competing designs that did take hold that the author favored for its simple/dependable operation, was the ‘tilt-back’ introduced by American Standard. (Photo 5) The author appreciated this design because he could manipulate the ‘timing’ of the flush by adding/subtracting tiny weights. (Out of his tackle box). PtP in his earliest tutorials (The Straight Poop—A Plumber’s Tattler) wrote Chapters such as: “Hot Rod Your Toilet Tank”. Those were different times, both culturally and state of the environment. He would not suggest you follow those instructions, today. Manufacturers have stepped up to their obligations to society, so to speak. You can find very efficient toilet choices today. *PtP was once admitted to an exclusive, experimentally focused medical clinic which happened to have terribly performing toilets. As a bribe, he wrote the manufacturer of one design of high performance/efficient toilet and offered to write a magazine article for the most elite publisher of the ‘enlightened builder’ genre, IF they would donate toilets to the clinic. When Pete wasn’t being treated, he was busy installing toilets. Regardless of the design of flush valve you might encounter, the sealing of the water in the tank is accomplished through the use of rubber type material, formed into preferred shapes for the valves seat (Photo 6). Rubber type compounds do break down over time, in water, and need to be replaced.

Regardless of the shape of the flapper and the seat in the base of the flush valve, when the rubber type compound of the flapper (or ball) deteriorates far enough, leakage begins. In almost all cases the leakage is silent and only by billing shock is one alerted to ‘something’ being ‘wrong’. Thankfully, most all of the different ‘flappers’ are economically priced. Over many years PtP discovered that the flapper (pancake) one manufacturer shipped with its toilet sometimes worked on other brands of toilet, also. He had a large collection on his plumbing truck to experiment with. Double Check Most municipal water utilities will happily send you via the Post, free, upon request, some potent, brightly colored die tablets to help you determine if you have a flush or a fill valve leak. These tablets are dropped (gloved hands?) into the tank and, in time (minutes) if the water in the bowl turns that color, you know the flush valves flapper needs replacement, or a seal in the Fill Valve has failed and is letting excess water into the Fill Tube of the Flush Valve. If that is the case the seal needs replacement. (Depending upon the age of the toilet (and a worst case), replacement of the flush valve itself might be required if a new pancake/flapper cannot prevent at leak at the Flush Valve seat.) Oh No! Replacing a flush valve itself can be a time consuming procedure but a motivated layperson is capable of doing it using my other books: “Installing And Repairing Plumbing Fixtures” and “The Straight Poop”, available at used book sources. The Straight Poop can also now be downloaded for free on the Net. Last Whale The last common source discussed for slow, silent leaks are automatic valves incorporated into irrigation systems. If you have automatic irrigation systems which are maintained by professionals there is little worry about faulty valves. But if it’s your responsibility, it’s worth walking the turf occasionally with an eye not just for dandelions but also soggy spots (especially near and around the valves). If it does soon get ‘dicey’ (severe drought) water pricing will take care of the dandelions (and probably/maybe even your lawn, or plantings) but you won’t want to be pissing away the then precious commodity in a futile attempt or paying an exorbitant water bill (if they let you). Perhaps the situation (this? time) merits a professional’s attention? There are other common leak sources and ‘situations’ that can affect your water bills but the topics we’ve discussed are the most prevalent ones and those easily diagnosed by the dweller of the property involved. Even if you don’t find yourself so impacted, in casual communications with those in your ‘bubbles’ you may be able to offer some valuable hints on the subject everyone will be talking about, and…help someone else? *In the 1970’s drought in California a particular ugliness arose (that wasn’t plant growth). PtP has empathy for those who by nature are green thumbs and maybe ‘don’t feel really alive’ unless they are caring for their gardens. (Pete’s first ‘outside of home responsibilities’ job was a Gardener’s grunt.) In California’s 70’s drought there happened to be a high concentration of “one-percenters” in the area, served by PtP’s water utility. These individuals did not care how much dinero it cost to maintain their 40+ acres of urban, manicured tropical forests and grounds. When the pain level of the general public (having to let their landscaping die) started spilling over into the ‘overflow tube’, there were bills introduced to allocate water (a specified amount) per person NOT by account numbers. It got bitter. I hope we don’t have to witness that once more. Ace In The Hole Hopefully this summer and growing season will come and go with little suspense and the sky will stay put and we’ll again soon be thinking about ski and boot rentals. PtP (nevertheless) plans on getting off his “gasoline plantation” forest homestead for the duration, just in case—harvesting oysters and razor clams in Puget Sound (knee-deep in fire-proof H2O!). When It’s ‘That’ Time Again, PtP

0 Comments

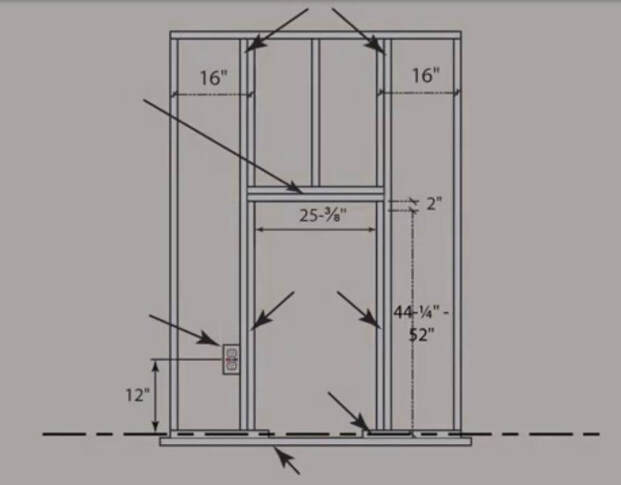

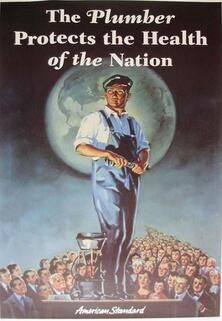

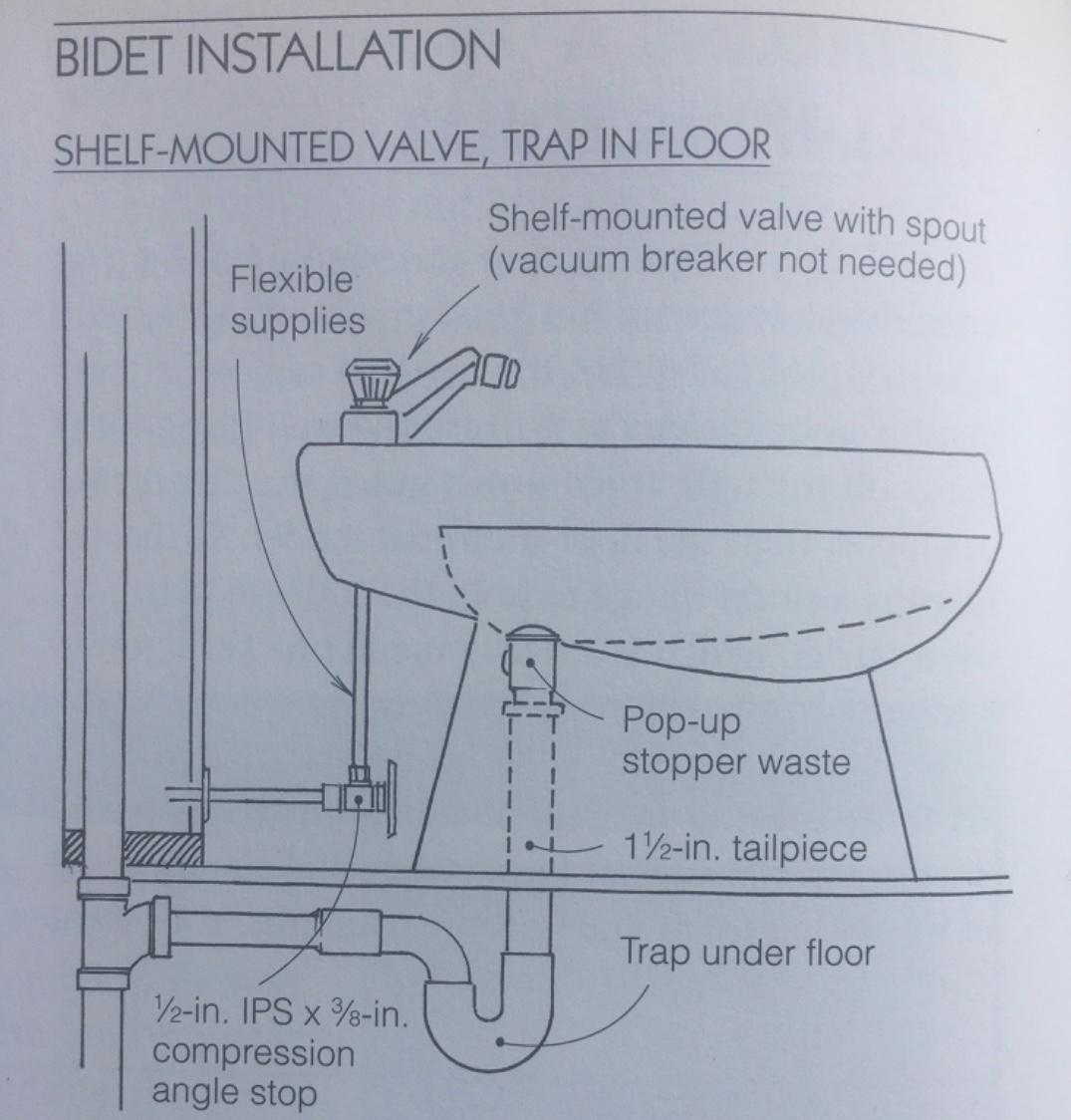

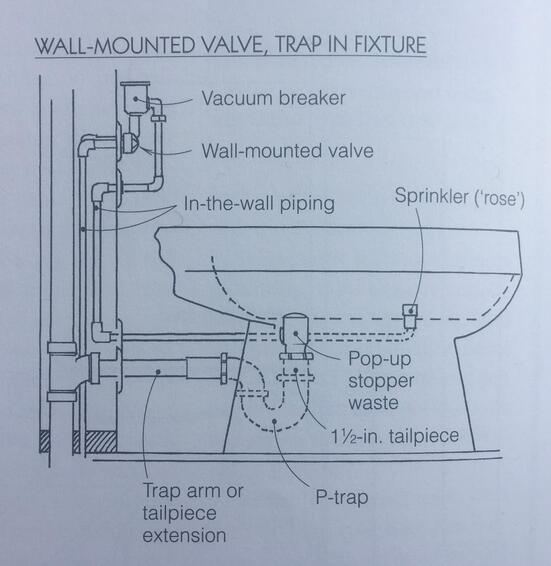

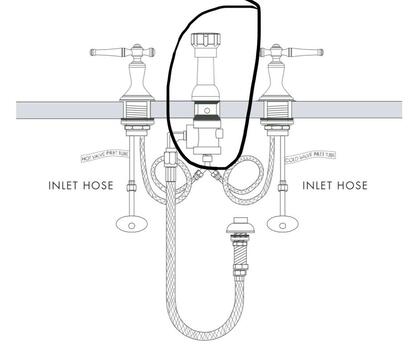

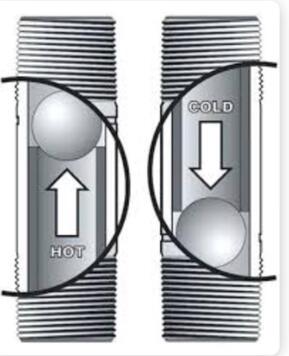

Greetings. Me wonders if in these COVID times whether the ‘shelter-in-place’ orders might be sending some of the ‘bored’ to areas of the WEB they’d not otherwise likely be going, like stumbling into ‘The Pipe’. For those of late who have been purchasing The PEX Edition of Plumbing A House (in spite of these pinched times), not to mention these most turbulent times, the author would like to thank and commend you.” On A Roll One reality very pertinent to our present circumstance is the public’s penchant to wiping out the shelves of toilet paper at their favorite outlets, once again. A good example of our ‘Freudian angst’ with an unmitigable function of human physiology? (Caveat: Pete the Plumber was recently seen with an armload himself at Wiley’s, his local market.) Toilet paper was a topic yours truly covered in some depth (Plan B) in a late post. Pete has long believed that should a mega seismic event or electrical grid collapse ever render a large metropolitan area’s infrastructure a lethal blow, loss of waste treatment facilities would be almost as debilitating as loss of drinking water availability. (You would then find the ubiquitous 5 gallon bucket as rare as the missing TP roll.) When PtP lived in Northern California’s East Bay for over 20 years, the knowledge that his drinking water traveled hundreds of miles and at one point very far away, through two, 100 plus year old, hand lain brick tunnels, crossing a major earthquake fault, was something that he would be thinking about as he dozed off to sleep. This present post is not going to revisit the TP quandary. But it is focusing on a subject that is intimately entwined with waste water treatment and TP: toilets. And, in this particular instance, a modern toilet design that is fast gaining a major niche with new and remodel architects and designers: the “inside-the-wall” (hidden reservoir) wall hung toilet known as Concealed Cistern Wall Hung (CCWH) (Photos 1, 2, 3, & 4). Because of their growing popularity the author figured this newer design was a timely subject to discuss. And/but there are a number of angles (issues) about this tank inside the wall wall-hung toilet that the author feels should be aired for the benefit of anyone who might consider incorporating one in a ‘new build’ or a remodel. In the past ‘good old days’ wall hung toilets were not that common to residential construction. Most folks encountered them in commercial office buildings, medical facilities, and maybe an occasional gas station or movie theater. These designs required ample space for their bulk. The flushometer supplied models (Photo 5) were ubiquitous. In the ‘way past’ PtP did install some in private homes. These occasions were for architects who had designed their own new homes and for clients with physical conditions that lent custom height toilet bowls an expensive imperative in a remodel. The wall hung toilets for these residential installations eschewed flushometers (for several reasons) and instead employed two-piece, ‘close coupled’ tank-to-bowl designs similar to (Photo 6). The design requirements to create a bowl which ‘hangs’ on the wall versus ‘sets’ (rests) on the floor (and which can support up to several hundred pound human bodies) mean that a lot more clay went into making the wall hung design. A lot more clay meant considerably more weight. To securely hold this heavy vitreous ware bowl to the wall requires/d a sophisticated ‘rack’ or ‘hanger’ if you will, called a carrier. The carrier in most cases is made of sturdy cast iron pieces which are bolted together and secured in position inside the wall. These carriers differ for wall type (wood stud or masonry) and brand of toilet manufacturer. The toilet manufacturer usually does not make the carrier too, but chooses one manufactured by one of several long established foundries serving the plumbing trade. Photo 7 is a carrier used with wood stud wall construction. Carriers used mainly for masonry walls are bulkier and more time consuming to install (Photo 8). PtP lobbied residential builders who wanted to employ one of these common wall hung toilets to frame the wall with a minimum 2x8 stud and preferably in 2x10. Even with 2x8’s the author recommended that several stud bays either side of the toilet be ¾ plywood with rock over. As a plumber, the author on too many occasions witnessed installations which were prone to leaking due to wall movement (flex) supporting a body during use. In one instance he recalls a leak service call to a home which had wall hung toilets (2) which were ‘back to back’ (in two separated bathrooms). A user of one toilet would feel a definite ‘bump’ and lift when a person in the other bathroom sat down on that bowl. A mini teeter-totter it was. The reason: two, heavy, elongated 2-piece tank-to-bowl wall hung toilets hung on a common, unreinforced 2x6 wall. Bulk Matters In the author's opinion, most architects and designers give the bathroom short shrift when allocating square footage in their floor plans. (Me knows it’s prejudice on my part.) Well, this issue of square footage (the less of) Pete recognizes as a big driver for the newfound embrace of the tank inside the wall wall hung toilet: Concealed Cistern Wall Hung (CCWH). Most residential bathroom space is too small. The conventional two-piece, close coupled tank-to-bowl set on floor toilet in many marginally sized bathrooms ‘hogs’ an unacceptable amount of the available space. Many times in these situations door swing can also be a difficult facet of the design to accommodate. The author believes this issue of less than optimum space is the biggest reason to consider employing a (CCWH tank inside the wall wall hung toilet (other than ease of maintaining cleanliness of the toilet and surrounding floor area). By eliminating the bulk (physical dimensions) of the tank from a toilet (whether it be wall hung or set on floor), as much as 9 to 10 inches can be “shaved” from the ‘from-wall-to-nose-of-bowl’ distance. Nine to ten inches doesn’t sound like much? When it comes to door swing and passage concerns it can make or break the feasibility of a potential or added bathroom. A New Pallet A traditional facsimile (Photo 6, above) for a two-piece close coupled wall hung toilet you might have encountered in the traditional American home of past decades is now being out competed by the CCWH (Photos 1, 2, 3 & 4 above). The space saving aspects of this design however can also be secondary to designers without square footage constraints. For them it’s an enhanced design opportunity. (‘Wall treatments rule’.) Designers can select an almost unlimited choice of color and texture for a space previously limited to merely a few different colors of vitreous. The last four photos illustrate this. (This newfound freedom of texture choice though can sometimes present a challenge to the Finish Plumber.) What A Rack The traditional wall hung (Photos 5 & 6 above) and the new on the scene CCWH don’t simply defy gravity to remain in place. The CCWH too utilizes a carrier. But due to the smaller size of bowl (and the less weight) the ‘rack’ (carriers) for the CCWH need no longer be a heavy (cast iron) ‘one-of-only-a-few-kinds’ of assembly. The carriers for the CCWH are manufactured from standardized mass produced steel square tube, usually ‘powder coated’ to resist corrosion. (Examples downstream). There are incorporated into each brand’s design of carrier, a few customized plastic brackets and tubular pieces which lend themselves perfectly suited to the economical, current expertise of the plastics industry’s mass production capabilities. Because of the many different CCWH bowl shapes found today, the toilet’s manufacturer markets the carrier also, as proprietary, and a ‘package deal’. What the foundries produced in the form of cast iron carriers for traditional wall hung toilet designs, those for CCWH are also a fraction of the weight. However, to accomplish both the support of a plastic tank (cistern) a n d hold a toilet bowl firmly on the finish wall, our new found friend is a much lighter but a physically more expansive (much taller) shape (the extra height means more leverage = strength.) So, thin wall steel material may be employed which is many times over cheaper to manufacture than the older, cast iron carrier designs. As mentioned, each CCWH carrier is proprietary to the manufacturer of the toilet. No mixing and matching. Assembling and installing the CCWH carrier (regardless of manufacturer) is vastly quicker and a joy in comparison to installing its cast iron brethren. The framing schematic (Photo 9) for one particular brand of CCWH is quite straightforward. Some others may ask for dado’s for blocking. And most framing options incorporate double studs. With accurate execution of the plan the carrier fits, and quickly. Big improvement over yesteryear’s cast iron pals. Who Me? Over the years PTP met a lot of frustration because of the way a bathroom and/or kitchen was framed. Maybe a strong structure, but much more troublesome to plumb. Upon encountering such conditions on a job the anguish was never less. As a result (the author confesses) ‘there was a chance’ PtP ‘cried in his beer’ to his fellow tradesmen. A good friend, Charles Miller (at the time Senior Editor of Fine Homebuilding Magazine) one day said to the author: “Pete, make your case. That would make a great article for the magazine.” The author did just that. The Publisher titled it: “Framing with the Plumber In Mind.” It’s a common occurrence of making living space that plumbers need to remove framing members dutifully installed by the builder that are in the wrong ‘orientation’ for the plumber to be able to install his necessary piping. The author always felt a pang of guilt when this occurred because he either had to ask the builder to alter their work or make the necessary changes, himself. Also, it was always the case of: whose job is/was it to do what reframing should/could be done to re-strengthen a structure after a plumber removed ‘just enough’ to complete his/her work? (Yours truly always offered his services when materials were provided and if it was within his skill set.) As mentioned, in the case of framing for a CCWH toilet, the carriers are proprietary to the fixture manufacturer, a reversal of the ‘good old days’. Because of this proprietary to vitreous manufacturer, the builder framing from an ‘Approved’ set of plans ‘better/will/should’ know what brand of CCWH is spec’d for the job, and frame accordingly. Now if someone wanted to pay PtP wages to frame for one of these toilets, I would not balk. But because the framing (Photo 9, above) is more involved than just adding or removing a stud or joist, the builder can always frame faster than yours truly, and by a lot. (He was rarely offered the job.) By studying the carrier frame in Photo 10 you can see the spec’d framing is integral (tight to) the carrier. However, “…no time for wobbly knees.” One merely needs a quality circular or hand saw, hammer or nail gun, and a little concentration and patience to create it. Thankfully for the layperson, most of the toilet brands offer free, well-produced installation videos on their respective websites. Carried Away Observe the two CCWH carriers (‘hangers/racks) in Photos 11 & 12. In these cases the tubular, plastic, bowl inlet (smaller) and outlet (bigger) drain fittings have black plastic dust/debris plugs in place. Both carriers have similarities. (Dust/debris plugs are yellow plastic in the other.). They both utilize thin wall square steel tube in their manufacture. Both have adjustable feet to allow the installer to achieve a custom height for the rim of the bowl. That’s a big deal. If you were another Wilt Chamberlain, you could have the toilet ‘way up there’ on the wall because the legs are standard square tube and easily modified. The dimensions of the poly flush tank (cistern) yours truly believes is where the designs begin. There has to be a ‘certain’ amount of water (derived at by a smart person) at a certain height, to attain velocity to flush the bowl. Cistern shapes differ among manufacturers. The tank/cistern is the size it is due to physics, plus it has to satisfy the need to ‘pancake’ into as little as 2x4 framing, on some models. Note: Some CCWH toilet manufacturers offer a carrier even for a 2x4 stud wall. PtP would recommend ¾ ply on entire wall, to hang a toilet on a 2x4 stud wall. The 3-in plastic Schedule 40 drain pipe serving the toilet will eradicate the full width of 2x4 lower plate/s. Water In…Waste Out The water supply to some makes and models of these fixtures incorporate specialized, usually copper and or brass, parts which are supplied by the manufacturer as integral to those others of the carrier (Photo 11, above). Also, the proverbial “flush handle” or “trip lever” in the case of a CCWH is a panel (Photo 13). Pushing on the ‘buttons’ results in activating parts (little hooks) which travel vertically up and down, lifting linkages to the flush mechanism below, in the tank. These linkages (moving parts) are behind the finish wall on an installed CSWH toilet. As a plumber with deep repair experience, this makes me a little nervous. I feel more comfortable when I can switch out a fixture's components or even the fixture itself without having to bother a wall. Flat Footed Photos 14 & 15 focus on the adjustable feet of a CCWH carrier. The installer sets the height of the bowl by what he/she notes on the approved plan; or, if desired, by drilling one’s custom positioned holes in a carrier body and adjustable leg, any height of bowl could be obtained. However, if the bowl height was radically different from the range of standard toilets it could become an issue if/when the sale of the property was initiated. If it meant however the ease and comfort for the long term use by a physically challenged property owner the decision would be an easy one. The Real Business There are two places (smaller one above the larger one) where tubular (plastic) pipes are inserted into the carrier (Photo 16). These fittings are proprietary thermoplastic fittings which are part of the ‘kit’. Into them go the trimmed-to-length pipe (for the particular thickness of the finish wall of a particular bathroom. (Rough stone?, custom tile?, plastic laminate?, mirror?, smooth drywall? All will differ.) Now notice the two openings in the back of the CCWH toilet bowl in Photo 17. With proprietary rubber seals on the ends of the trimmed-to-length plastic pipes, a waterproof seal with the vitreous bowl on final assembly is attained…(See videos, by manufacturers, on YouTube.) Now look at Photo 18. The Schedule 40 PVC drain protrudes up through the lower plate with remaining wood around the hole, because the framing is larger than 2x4 stud wall. Another look at the photograph reminds the reader that the drainage continues out and down. To where? Straight down the wall to a lower story bathroom to pick up more fixture units before exiting the structure? To a crawlspace under a first floor before turning horizontal? What about those with slab foundations? On new construction or additions slab is ‘no problema’. What about a remodel on slab? Well, Photo 19 & 19a tell us that with enough money to throw at it, builders like Ed Marciniak (E/M Design) will happily saw up your slab foundation (and put it back) so you can have a CCWH wall hung toilet. For those lucky readers with the budget to ‘do something’ with, there are some facts PtP wants you to know about before you get your hopes up, too high. Seat of Power Due to the many more different shapes of CCWH bowls, (Photo 4 above is an example), each model has its own uniquely shaped seat. Specialization always colludes with increased cost. A replacement seat can command a hefty price because there is only one manufacturer making it. If you have the bucks to afford one of the real ‘spacey’ toilets, like Photo 4, you might think about also picking up a replacement seat (now) and putting it away for a rainy day. Availability could also be an issue, way down stream. Another aspect of the above sub-head (Seat Of Power) is just that: Power. In this case, electrical power. The ever more popular bidet seat that has all the “bells and whistles” needs electricity. Most CCWH toilet manufacturers offer a custom bidet seat to fit their particular bowl shape. Bowls so equipped will have integral plastic tubes (conduit) incorporated into the hanger for water supply tubing as shown in Photo 20, below. These conduit tubes are preformed or are ‘easily bend corrugated’ and come as a component of the carrier. For the person wanting a CCWH with an accompanying custom bidet seat (from the same manufacturer), the carrier (for such) most often will be supplied with these conduits so there will be no exposed electrical cord or water supply tube to spoil the aesthetics of the design. Often then there is no adding a bidet seat as an afterthought (without having exposed cord and tube if you could find one to match the bowl). In the framing plan upstream you’ll notice an electrical outlet on the lower left. This location may differ between brands (on whose models of bowls are ‘drilled’ (cast passageways) for electrical cord and water supply for the proprietary bidet seat). Photo 20a is an example of a custom bidet seat made by the manufacturer of the toilet. Well, that’s about the shape of the article the author had in mind. But before closing this piece he wanted to share some general concerns/facts about CCWH’s that might help a reader decide whether they might want to paddle down that stream. Job Site Realities PtP asked his San Francisco son building contractor (Baywardbuilders.com) what comes to mind when he thinks about Concealed Cistern toilets, and what he shares with prospective clients who inquire about them. Dan mentioned the following topics. They were all familiar to the author. As follows: Space CCWH’s can save as much as 9 to 10 inches of floor space. That is crucial for ‘tight’ bathrooms. Hygienics CCWH’s make clean up a breeze. No more toilet base to clean around – mop glides right underneath the whole thing. Also, no joint space between tank and bowl for moisture to collect and fester. No more condensation from porcelain water tank contributing to dank bathroom conditions. Ergonomics Adjustable legs on wall carrier allow for fine tuning of your preferred toilet height. No longer limited by factory options. Noise Rushing water noise from plastic tank [cistern] in the wall emanates from behind the flush control plate on the wall in addition to the typical toilet bowl flushing sounds. This is potentially louder than some of the quieter tank toilets with porcelain tanks. Installation Considerations/Challenges CCWH’s are ideally suited for new construction bathrooms or full remodels because you need to fine tune the wall framing for the particular wall carrier unit. Even with slimmer 2x4 wall carrier models, you may still want a 2x6 framed wall. Although doable with 2x4 stud wall, it gets tricky at the bottom where the drain discharge pipe penetrates the floor. On Geberit brand carriers, the discharge pipe actually protrudes into the plane of the of the wall board that gets installed over the carrier (causing a very slight bulge). In tile wainscot situations, the tile will ultimately cover the drain pipe, while sheet rock will result in needing a gap and a ‘thin veneer’ of drywall ‘mud’ at this juncture (instead of a ‘full thickness’ of wall board/sheet rock). Alternately, by using 2x6 wall [or deeper] instead of 2x4, you can install the carrier back another ½-in. or more, placing the discharge pipe safely into the wall cavity behind the finish wall board AND it allows you to install plywood backing at the bowl mounting area to increase rigidity of your wall and reduce flex movement of the toilet bowl. This is crucial for tile wall wainscot applications where tile or grout may crack from any movement. Setting the carrier back further into the wall cavity also reduces sound transmission by preventing direct contact between plastic tank [cistern] and the wall board. This will also allow for packing the wall cavity with insulation for even greater noise reduction. O-ring Sealing To insure perfect sealing of the plastic inlet and discharge pipes (of the carrier) to the behind the toilet bowl cavities, be sure to employ high quality plumber’s ‘grease’ (Photo 21) or even consider using a ‘touch’ of silicone sealant (in lieu of) to ensure a long-term water tight seal. In Closing The employment of CCWH’s sometimes lets one create a full bath out of a half-bath, or a different, square foot challenged space. Photo’s 22 & 23 by Baywardbuilders.com, show how a small half-bath (plus sharing a junior portion of a small adjacent closet) was remodeled to a full bath (Roman tub included, with shower) complementing a residence with two other full baths. By employing the CCWH the hair care demands of a four person household, three of which maintain long hair, makes life much easier. Well, that’s going to be ‘it’ for this topic, for now. I hope you don’t feel cheated by your time investment. With luck we’ll both ‘be here’ in several more months, when this old man finds inspiration to put another one “In The Pipe”… PtP Greetings To One And All Crazy Times Between hurricanes, a recession, and a pandemic, how are you managing? PtP has been hunkered down and keeping busy with hobbies which explains his of late word scarcity. He though, has noticed an uptick in book sales and readers’ questions. He figured this might be due to a financial squeeze on the planned, previously-to-be, contracted projects of his reader? The possibility of losing audience to Covid occurred to him too. (How many might now be m.i.a.?) Yours truly is of an August age which has been recently more than well informed on healthy pandemic habits. So methought this post would be the perfect ‘couch-time’ activity to keep old Pete inside and ‘distancing.’ Now, due to WAY too much shelter in place electronic device time, the author has noticed a flood of advertisements pertaining to an aspect of my last post: toilet paper and personal hygiene. These online adverts are urging the public to adopt a different method of personal hygiene, and be ‘done with’ toilet paper by using pressured hydro to wash your bum clean, instead of wiping post poop. The author’s concern with this new on-the-scene toilet bidet involves a physics issue, and by illuminating the functioning of traditional bidets he hopes to assure your possible adoption of a toilet bidet be a safe practice. This is underwritten by the addition of a little known, important plumbing device NOT necessarily included in the inexpensive, foreign designed and manufactured toilet bidet now appearing in so many on-line adverts. This little gem of a plumbing part is discussed and illustrated in The Lone Ranger To The Rescue, near the end of the article. As for toilet bidets, while cruising the NET in search thereof, the reader will see hundreds of ads for the same means (and mostly the same product). It’s a hand held bidet ‘handset’. It consists of a nozzle/handle; a flexible metal hose; and a diverter valve. The diverter valve allows the existing cold water supply for the toilet to be the source for the handset also. This particular design of bidet is marketed for cleaning human ‘bottoms’ following a poop, without the need for toilet paper (or much of). PtP is all for this new campaign, but as he mentioned above he wants to raise a red flag (and offer a few complementary suggestions). Before we slide into this technical ‘head’s-up’ topic, the author first wants to air some historical perspectives of the long in use bidet, as we’ve known it. Little Horse Water, and especially moving water, from time immemorial has been utilized for dispensing with human waste. The Minoans, Etruscans and Romans were especially adept at it. Where the author would like to launch this post is when we begin to see objectively depicted (posh) ladies astride a bidet. (Photo 1): Men, no snickering. With your adoption, you would find your appreciation thereof increasing as you aged, in dealings with overly saturated methane, for one. OK. Now. Why is a bidet called a bidet? Well, if you haven’t already guessed, bidet is old French slang. It referred to a ‘little horse.’ When one (I) look at renderings of ‘bidets’ of early eras (Photo 2) the saddle shape of the fixture and the fact that the person, when using, sat astride only supports the slang story that stuck: little horse. These artfully rendered female members of the upper crust (most) were not using the bidet as a chamber pot but rather attending to their lady parts with (at the time) a quite convenient pool of mostly (for the times) clean, and most probably warmed water. Then, the fixture was portable. It was a vessel one squatted on and with the use of finger/s and more, cleansed themselves. Many who trusted the use of as birth control had big surprises. It wasn’t until we see stationary, piped bidets first appearing in American upper class housing during the early 1900’s (Photo 3) and becoming more common in 1940’s following World War 2, that directed flow and temperature of moving water became fashionable in this exercise. The author will have more to say about this further downstream. In the early 1960’s, apprentice Pete was becoming familiarized with the installation and workings of the two basic designs of supply and drainage plumbed, free-standing bidets, those accepted by municipalities’ and States’ building and safety codes. The ‘new ones’ he worked with then still utilized a p-trap in the floor. His at the time employer (Me and Angie) served a world-traveled clientele. Pete right away appreciated the complexity of fittings incorporated (and required by codes) for modern bidets. One of the two basic designs has fewer parts than the other. The fewer parts version is cheaper to manufacture and cheaper to rough plumb. But both designs though have to wrestle with physics to be accepted by codes. Both types of free standing (modern) plumbed (supply and drainage) bidet designs have a pop-up stopper (like bathroom sinks) to form (when desired) a pool in the bowl, (Photo 4). And, both designs employ ‘sprinkles-to-blasts’ of your choice-of-temperature water, in their functions. (That temperature selection aspect is a big deal and we’ll get into that shortly.) Because plumbers are known as protectors of the nation’s health (Photo 5) yours truly wanted to raise an issue concerning the recent effort by some to ‘dump’ toilet paper in favor of a hand held toilet bidet, for this purpose. This new interest blossomed alongside a Covid-19 related consumer supply problem: TP availability. However, the aspects of both temperature and directed water for said purpose, the author wishes to raise. PtP will begin with water temperature before water flow choices are discussed. Ice Cube The author admits (confesses) that the ‘morning after’ an over-indulgent (rack it up to youth) consumption of abalone stuffed Mexican hot chili peppers (in Mexicali), he discovered the most important use there is of an ice cube. But since these occasions (thankfully) were far and few, additional desire to have coldness ‘down there’ was not extended. If you are someone who, in spite of being limited to only cold water, would be interested in living with one of these remarkably low-priced off-shore sourced hand held toilet bidets now being advertised, PtP congratulates you. (Anyone who can make the adjustment to using only cold water this way: all the more to you!) With traditional, permanently installed bidet fixtures, to have them accepted by states and communities everywhere, they have to have met some important safety/sanitary codes, one of which keeps ‘everything’ directed in the safe direction: downstream. This is where the physics issue aforementioned comes into play. Back Siphonage In the plumbing code of jurisdiction for the author (Uniform Plumbing Code), a condition defined as a Cross Connection is the plumber’s greatest worry/concern. A mixture of waste water into a source of drinking water has long been known as an accomplice to death and ailment. It is an action that plumbers just cannot allow to happen. Today’s manufacturers of sanitary fixtures have to provide for a function that does not let waste water (water used) have any possible way to mix with fresh water supply. With plumbing fittings and materials, what the non-plumber effects in his/her bathing routine (by their own actions) must not constitute a Cross Connection. Below is the actual wordage of the code. “A connection or arrangement, physical and otherwise, between a potable water supply system and a plumbing fixture or a tank, receptor, equipment, or device, through which it may be possible for nonpotable, used, unclean, polluted, and contaminated water, or other substances to enter into a part of such potable water system under any condition.” (Spoken with beautiful legalese.) An accidental back siphonage of waste water from a bidet would constitute a cross connection. In the case of the permanently installed bidet fixture, one method to accomplish this safety/sanitation level is with the addition of an anti-siphon valve (Photo 6) on the water supply portion. (This valve and piping illustrated was common on earlier models which left the pipe and fittings exposed behind or on the back shelf of the fixture. To appear modern (at the time) the manufacturers decoratively electro plated the parts in chrome and more expensive finishes then in vogue.) A later style of free standing bidet popular to present, illustrated in Photo 7, the shelf mount, that maintains its favor with authorities (illustrated in: Installing And Repairing Plumbing Fixtures) employs an air gap (gap of free air). This design of bidet directs water flow to the bather’s anatomy from above, versus below the flood level rim of the fixture, as in a ‘rose-sprinkler’ design (Photo 8). The gap of air between the water issuing the shelf mounted valve spout illustrated in Photo 7 and the lower altitude of a bather’s exposed flesh, establishes a “safety distance” against any possible back siphonage and resulting cross connection should water supply be interrupted. Yours truly will have more to say about this choice, downstream. All quality plumbing manufacturers like to put their name or mark on their products, often with an additional mark of a regulatory agency for extra effect. For about a third of the lower 48 United States, reputable sanitary fixture/valve/equipment manufacturers mark their products with: UPC, sometimes within a shield facsimile. UPC are the initials of the Uniform Plumbing Code. Fixtures and valves that can exhibit that mark guarantee (with proper installation) that no back-siphonage occurs with their product, among other imperatives. To earn this sign of safety, manufacturers incur considerable design and manufacturing expense. Does the hand held toilet bidet product being sold online and even in some brick and mortar outlets exhibit the mark of the Uniform Plumbing Code? Or others? If it has passed UPC requirements by spending the bucks doing so, it would only make sense to advertise that fact with a UPC or other nationally recognized code symbol, prominently, somewhere on the item of manufacture, no? This brings us to the second point of interest in my argument: direction of flow for both waste and supply. Check Valve The average person in the US uses 9 squares of toilet paper per poop. Do the extrapolation and the possible environmental rewards of using less are plainly seen. (According to the Natural Resources Defense Council, toilet paper accounts for 15 percent of deforestation.) However, this switch of hygiene habits should be done safely, without the possibility of ‘cross connection’ through back siphonage. Does/did any possible hand held bidet product you purchase/d or are evaluating, have such a mark of approval like a UPC mark? If it doesn’t, does it mean one should not purchase it? Though PtP is rooting for toilet bidets, he does not want this to become a public health trade-off due to laypersons’ lack of code knowledge. If it’s going to happen, yours truly would like to see it safely handled. He proposes the addition of a consumer supplied, very reasonably priced check valve, readily available by a respected US manufacturer for just this purpose. (I’ll tell you more about this product downstream.) More on Anti-Siphon From a ‘rose-in-bowl’ plumber’s installation schematic (Photo 9), we are looking at a cross section of a rose/sprinkler anti-siphon and diverter valve, in one! This specially designed valve serves both a function change (directed spray or rinse-down-and-fill bowl), and at the same time provides the service of an anti-siphon valve. This valve prevents spent water collected in the bidets bowl from back siphoning up into the fresh water supply system through the ‘rose’/sprinkler. (The same precaution is taken for landscape sprinkling and watering.) The lower supply valve shown on the right would be the cold water supply. The hot water supply valve would be replicated on left side of this symmetrical fixture. This design of traditional bidet where the supply valves are under-hung (with trim above), on the back ledge/shelf of the vitreous fixture, and which through tubing connections, water is routed to the traditional rose (sprinkler head) in the bottom of the bowl, has long been the standard bearer of ‘top drawer.’ (And before it, the ‘in-the-wall’ valve and supply with sprinkler.) Back Shelf/Ledge The newer, second major free standing bidet fixture (Photo 10), (the design mentioned prior and illustrated in Photo 7) referred to as a “back shelf” design, again, escapes the requirement of the anti-siphon valve by the means of its natural (physics) air-gap. The bowl shape and ‘faucet’ style valving choices are quite varied, Photos 10a, 10b & 10c. What with this change in valving, where the mixed temperature water is emitted from above the flood level of the bowl, angled down onto the bather’s choice of exposure, affords a ‘no chance’ of back siphonage/cross connection. There’s no way for waste water (bouncing off the bather) or left in the bowl, to climb up and out of the bowl and be ‘accidentally’ siphoned back up into the valve and supply piping. Can one do all of the ‘things’ with this back shelf design as one can do on/with the “rose in the bowl” design? The answer is no. But, if you haven’t been introduced to the ‘rose’ first, you’ll still be very impressed, and hopefully become an adherent. Alternatives Most Americans are probably already feeling too financially encumbered in the time of Covid-19 to make or re-make bathrooms to accompany stand-alone bidets. Until lately, manufactured options have been the toilet seat bidet, made popular in my region by the Toto Manufacturing Company, such as Photo 11. This Japanese company has been very successful selling their version of toilet ‘seat’ bidet ‘attachment’/add-on, in the US. Now many competitors compete in the “seat races.” But, predominantly, they too are ‘sanctioned’ anti-siphon and also require an in-wall electrical supply. Plus, one look at pricing, and if your heart is still in it, Pete says: “Go for it.” Not many readers are in the position or mood to go that direction however, especially now, thus the interest in cheap alternatives. The Lone Ranger to the Rescue Wanting to do his part in rooting for the ‘entry level’ hand held hygienic device for the toilet (toilet bidet), the author has a simple recommendation for the ‘questionable’ choices on offer: Put your own check valve on it! Thanks to the American Standard Manufacturing Company for making available their wonderful little product, the M962520-0020A check valve (Photo 12) this is easily and economically accomplished. This check valve comes to the rescue. With this plumbing part installed on either end of the flexible toilet bidet hose (Photo 13), fresh water can only travel in one direction. No going backwards. No cross connections. In Luck Because standard US pipe threads (Photo 14) are traditionally used in this country throughout the ‘rough’ and ‘finish’ plumbing schedules, foreign competition now shipping to the U.S. equips their offerings with US threads. Luckily that allows us to employ the American Standard check valve in conjunction with foreign offerings too. The author recalls the 1970’s when he first started encountering foreign made plumbing products. On the west coast the Germans landed first. Great ‘old world’ quality and no plastic, but one needed to purchase extra adapters to make threaded connections. We (U.S.) didn’t take very long though, to jade them however (lower the quality). Now, it’s lots of plastic too (yet superior to ours) but US threads. Regardless of country of origin, now you can do something for public health and prevent back siphonage: include the American Standard Shower Hose Check Valve on your non UPC sanctioned, hand-held, toilet bidet kits. There are two additional aspects of indulging the hand held toilet bidet the author would like to air before ending this post. Be Kind To Yourself The author has spent time in primitive conditions in the northern wilds where your butt could stick to an outhouse toilet seat like a boy’s tongue to a frozen metal flag pole. If you cannot afford (at this time) an expensive ‘seat’ bidet or free standing ‘standard,’ providing warmed water, and want to experiment with toilet bidets, PtP would like you to know about two things. The first is a diverter valve for bathroom sink faucets (Photo 15). This device allows a person with a conveniently close-to-toilet lavatory basin faucet the ability and luxury of having a temperature mixed hand held toilet bidet, on the cheap. When you can have the pleasure of having water at the temperature of your choice, the odds that you make a successful bridge between hand held toilet bidet hygiene and 9 to 27 or more squares of TP are greatly enhanced.  Photo 15: This diverter valve threads onto a bathroom lavatory faucet spout after removing the faucet aerator. An aerator adapter may be required depending upon your faucets manufacturer. It allows for temperature mixed water for use with the hand held toilet bidet. This particular valve was discovered on eBay and it had no manufacturer’s name or model number. Round or Elongated The second ‘thing’ yours truly wanted to mention is a factor to consider when your toilet bowl is round versus elongated. Back Shelf and rose-in-bowl free-standing bidets are, by design, longer bowls than a standard, round, 12-in. rough toilet bowl, allowing for hand movements. Instead of having the pre-positioned sprinkler or jet of mixed temp water from a standard bidet, or a ‘seat bidet,’ with a hand held bidet on a hose, you the bather must, by hand position, get the flow of water to where you need/want it. In choosing a hand held bidet ‘head,’ which bowl you have, round or elongated, can spell your level of success and enjoyment. Using a hand held toilet bidet is more physically challenging in conjunction with a round toilet bowl than with an elongated toilet bowl. In this situation size matters, in favor of modest. Definitely for round bowls but not excluding elongated bowls, depending upon your choice (size/bulk) of bidet heads, an open front with lid toilet seat combination (Photo 16) might be well worth the expense, allowing sufficient space to manipulate, effectively, your eventful choice of head. The case of hand held toilet bidet heads could prove a parallel with hearing aids: rarely is your first and even second choice the one you settle on for the longer haul. Be thankful again for the standard ½- in. female iron pipe connections on hoses, and the standard ½-in. male pipe threads on heads, noted above. This allows you to try as many different available heads as you desire. And, if you have satisfactory temperature desired flow rates, you might find yourself owning an additional head that is better suited for other tasks. Well, the author hopes he didn’t lose too many readers on the trail. For those who persevered though, he hopes you found it worthwhile. For all of us, I wish the quickest and safest end to Covid-19. Until Next Time, PtP Hello ‘In the Pipe’rs. Crab season (see upstream post) ain’t over yet but yours truly felt motivated to paddle ashore and broach a subject which he felt was very timely. (Salt water and cell phones are a dangerous pairing.) It’s a subject close to the author’s heart (but even closer to his anatomical sphincter). It’s a subject which PtP feels if not illuminated at this time, could cost the world public (those with flush toilets) even more financial burden than what they might already be suffering due to income loss from the fallout of the Novel Coronavirus, plus: clogged toilets and drains and the fees to ‘get them back on line’? This post takes a look at the dangers of substituting the wrong paper for genuine toilet paper. The author believes that at no other time in recent history is this scenario more probable due to present circumstances. First, there were the Pentagon Papers. Then we got the Panama Papers. And now, lo and behold, we have the Corona Papers. Who would have ever thought the corner stone of personal hygiene, toilet paper, would become the poster child of a 21st century global pandemonium. (Pete the Plumber once came to the rescue of a Mr. D.E. and family (frozen water pipes), so yours truly felt entitled to coin: Corona Papers.) According to the site: HistoryExtra, the earliest known record of using a form of ‘paper’ for this hygienic chore comes from China, in AD 589. However, it was a Yankee in 1857 (New York) by the name of Joseph Gayetty who first started marketing commercially packaged ‘toilet’ paper, Photo 2, below. His were individual sheets with our man Joseph’s picture printed on them. However the masses had to wait another twenty-years before the introduction of perforated rolls (and even then the occasional splinters were a problem). The ubiquitous, super soft, layered fare we know so well today was a twentieth century dream come true. Isn’t it ironic that in the span of about one month a disposable commodity selling (normally) for ‘peanuts’ suddenly became a new gold standard, one everyone clambering for. Our aversion to employing anything else (historical standby’s and Plan B’s) speaks volumes. Pete the Plumber (yours truly confesses) for years has harped to anyone who would listen that only poop and TP should be flushed down the toilet. This admonition served/serves a double purpose. The first concern involves drainage piping and the second concern involves septic systems and sewage treatment plants. Those inaugural individual sheets and albeit splintery perforated rolls are a far cry from today’s quite technical ‘bath tissue’. Today’s TP is made with short cellulose fibers. When the paper is deposited in the toilet bowl and becomes saturated, it breaks down (dissolves) into tiny bits. This assures that it will flow through the sanitary drainage piping without causing a stoppage (clog). The pliable nature of our poop (in most cases) presents little resistance to transit within the piping. (Japanese toilet designers use mochi dough to model human poop to test new toilet passageways.) Most other forms of paper are not made of short fibers designed to dissolve in water. As a matter of fact, household ‘paper towels’ purposely use longer, in-twining fibers to produce a paper resistant to breaking down in water. Paper towels, even if they manage to slide through the toilet passageway will hang up in the drainage piping because of their bulk. Homeowners who need pay the drain cleaning contractor learn this lesson early. Inhabitants of living space served by septic systems are faster learners than a populace served by municipal sewage treatment facilities. There are several concerns involving living with a septic system that the municipally franchised need not concern themselves with (mostly involving bacteria killing household chemicals). But the use of any papers not designated short fiber toilet paper is equally problematic to both types of sanitary system. “In the literature” the author has read conflicting accounts on the biodegradable-ness of short cellulose TP. Some claim it does not biodegrade. Others claim that ‘in time’, it does. As the author has been known to confess skipping chem lab, on too many occasions, he has no chops to question either camp. But, he knows of occupied dwellings operating on septic/leach that never need “pumping” or “additives”. This tells the author that a well designed, well fed septic system takes care of itself. Just don’t poison it. Biodegradable TP is widely available for those on septic who wish to “get the best mileage” out of their hard working bugs. A caveat: biodegradable toilet paper is not as soft as the standard fare. On a different note: Another one of Pete’s ‘hot button’ sanitary paper concerns involves the manufacture of products marketed as flushable. Flushable does not connote dissolvable or biodegradable. Sewage treatment plants end up having to operate sophisticated mechanical systems to intercept, then extract (tons and tons) of non-biodegradable trash. Flushables a majority among it. Then, more expensive rolling stock is required to transport the trash to a land-fill. Who pays the price of recycling what private industry designers concoct from non-degradable material? The City/County/State taxes it’s citizenry to pay the cost of ridding themselves of such garbage. (It’s just going to another spot of ground with a much lower property tax.) The old “vote with your feet” slogan, twisted by twisted minds to shout “vote with your butt” might be heard some evenings, now. The only way to stop and then reverse the “non green” solutions is to educate the public (the market, by association): “Do not make it with ‘these’ materials.” Cut the demand and you see companies rethinking former actions taken. Only then will we begin to reduce the amount of land fill for consumer non-biodegradable materials and lower the costs for sewage treatment. Which brings me back to my old slogan: Flush nothing but poop and toilet paper! For those interested, inexpensive, temperature/flow controlled hand held toilet bidets (served by lavatory faucets) are available for reducing TP usage. Where we end up our battle with the Covid-19 virus is anybody’s guess. But one thing you can be assured of is that tissue mills and paper companies are operating at full employment (with big smiles). How much longer the hoarding of the new, “soft white gold” continues, is an unanswered question. But the industries involved with producing America’s TP are, presently, enjoying robust order sheets. How fast the public stops panic buying and production falls back to pre-pandemic levels, we’ll see, first hand. The author had a couple of automobiles in his early past that used a roll of standard toilet paper as the filter material. (Photo 3) Would that design, after all the present hullabaloo has died down, be worth resurrecting? O.K. That’s it. The fish heads are beautifully stinky. The pot is baited. Short rod and surf rod lashed to deck. It’s back out with the tide, lamps lighted… Until Next Time, PtP GUEST BLOG:

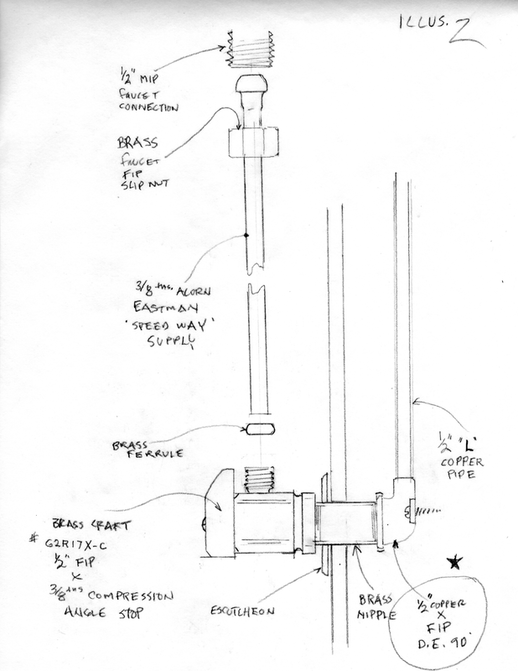

Hello In The Pipers! The “old man” is taking a short break while he prepares his latest pipe dream project - a crab pot kayak! Hopefully all those years of chasing leaks means he won’t take on water and we won’t lose him to the crabs of Puget Sound any time soon. In the meantime, I have a little plumbing story to share with you all…. As a kid growing up watching my dad wrench on pipes, I learned just enough about plumbing to think I could do it too. That inherited knowledge has come in handy plenty of times over the years as a homeowner and later, as a general contractor specializing in residential remodels. With that limited expertise in my back pocket, it’s often difficult to resist the temptation of taking on some of the little plumbing fixes and upgrades that accompany our frequent bathroom and kitchen remodels to save some time and even money. The (good) plumbers in my market are frequently very busy - “you can’t fit me in until when?!?” and expensive - “you guys are billing over a buck and a quarter per hour now?!?” Hmmmm…. well, I have a set of adjustable wrenches too. Maybe I’ll just do that last minute faucet replacement myself and save us all some trouble. Ha! If only it ever worked out that easily. In this particular tale, we had just wrapped up our final day on a kitchen remodel for an adorable young family in San Francisco. Their condo conversion was on the 4th floor of a building that was presumably built sometime in the ‘teens. Mind you, that would be the ‘teens from 100 years ago. The project had gone very well, with only the usual level of surprises and cost overruns and they’d been perfect clients through it all. I knew they’d spent more on this remodel than they’d planned and had stretched themselves a little thin, especially with their second child soon on the way, but they were otherwise very happy with how everything had turned out. It was early Friday afternoon as the Mrs of the house and I completed the final walk through, exchanged the final payment check and said our final “thank you’s”. As she walked me to the front door, she stopped at the little “washroom” off the hallway. This cute and very original half-bath had been used by my crew throughout the kitchen remodel since we didn’t have space for a portable toilet down on the street. “Oh, wait….. I want to ask you one more thing before you go”, she said as she flicked on the washroom light and grabbed a box from the floor beneath the sink. It was a new faucet she had picked up someplace for “a song” and she wondered if it was a suitable replacement for the old, tarnished original. I opened the box and sure enough, it was compatible with the sink and would work fine. It was a tasteful modern interpretation of a classic widespread faucet and it actually looked really nice with the sink and would finish off their otherwise pristine half-bath. I was quite pleased to have their project all wrapped up and taking on one more item didn’t exactly thrill me. But I would also never leave a good client hanging, so I contemplated the next move. Getting my plumber back out for such a small task wasn’t going to be easy, cheap or convenient and the more I looked at that gleaming faucet, the more invested I became in seeing it installed. I then realized that the tool kit in my truck had everything required for installation and in that moment it became impossible not to offer to swap it out for her myself, as a parting gift on a project that had gone so well. Should only take me about 20 minutes! I’d be home before the Friday commute even began... Well, I’m sure at least a few of you have heard the old maxim, “a good deed never goes unpunished”. I probably should’ve taken a closer look at things before offering up my help, but I didn’t recall anything out of the ordinary about the old sink or faucet. And the only unusual detail on the new faucet was the factory-installed braided stainless steel supply hoses, but they had the garden variety, female ⅜” compression fittings that we use all the time, so I figured -- no problem! Well, things got off to an unexpected bumpy start right away when I first tried to shut off the water to the faucet. The old angle stops below the pedestal sink were as original as everything else in that bathroom and not like anything we install today. They were thick, smoothly polished & plated castings with chunky 4-cross handles. They looked like they belonged on a steam ship or an old submarine. And they were quite impossible to turn! We had learned during the kitchen remodel that the apartment didn’t have its own water shut-off, so if I couldn’t get these angle stops to work, it would mean shutting down all 6 floors of the building. And that would mean a 24 hour notification to the other occupants, a return visit, the usual gripes and grumbles about inconvenience, plus the very real nightmare possibility of dislodged scale and crud from the 100 year old pipes clogging faucets, shower heads, dishwashers, washing machines etc. throughout the whole 12 unit building after the water came back on line. That was a nightmare scenario I was not prepared to endure for “a favor” and I was beginning to worry that I would have to renege my offer. Then I remembered an old trick I’d learned from my Pops -- Pete the Plumber. We all know how plumbers use their propane torches to sweat copper pipes, right? Well, they come in handy for so much more: thawing icy pipes, cleaning gunky tools, warming cold, leftover pizza, to name just a few. I own a plumbing torch of course, but didn’t have it with me on my truck so I asked the lady of the house if I could borrow the next best thing - a hair dryer! It took a good minute to warm up those hefty angle stops and soften the hardened stem packing, but it eventually did the trick. The heat probably softened the crusty old rubber washers too because lo and behold, those ancient angle stops still managed to shut off the water to that old sink. It then took me less time to remove the old widespread faucet and rigid supply tubes than it did to shut off the water. Should take just another 15 minutes or so to get this faucet installed and I’d be on my way home for a cold beer and a satisfied early start to my weekend. But not so fast! While I was wiping crusty (heat-softened) pipe thread compound off of the old angle stops, I realized I’d failed to take notice of the larger outlet size. It was noticeably bigger than the ⅜” fittings on the new faucet supply hoses and coarse thread to boot. Since I couldn’t swap out the swaged-on factory installed hoses, I would need a step down adapter for the angle stop. No problem, I thought. These looked like ½” coarse NPT thread. A quick run to the ‘Big Box’ for the parts and I’d be able to wrap this up before traffic got bad for the ride home. I’d also pick up a small tube of clear silicone for the faucet bases and a roll of teflon tape while I was there. Have you ever gone to the ‘Big Box’ hoping to find something a little out of the ordinary? A: it doesn’t exist. Or B: it does, but the young kid working that department doesn’t know what you’re talking about or where to find it. Or C: they do have what you need and the computer says they have 14 of them in stock but there is only one in the box on the shelf when you need at least two. It was scenario ‘C’ that day. Luckily, the other nearby ‘Big Box’ answered the phone and was able to confirm they had some more on their shelf. So after a little detour I had the two “BrashCraft” ½” FIP adapters in my hand for less than $4 each. At least I was in and out of that second “Big Box” in less than 20 minutes! Friday afternoon traffic congestion was starting to pick up and when I finally returned to the job it was pushing 3 o’clock. I confidently told the Mrs that I would be wrapped up and on my way in another 15 minutes or so. I could almost taste that beer waiting for me at home…. Alas, I would have to wait a little longer for that refreshing beer. Out of habit, not doubt, I did a quick test fit of the adapters on the angle stops before applying teflon tape to the threads. Hmmm…. these are WAY too loose. No way the teflon tape is going to take out this much slop. Dang, these adapters aren’t going to work at all!! What gives?? I’ve never had problems with “BrashCraft” stuff before. No, it was those old angle stops -- they were some funky size between ⅜ - ½”. So what to do now? Accept defeat and reinstall the old faucet? Too embarrassing. Try and find some way to connect old-style rigid supply tubes to the factory flex lines of the new faucet? This was all exposed - that would look awful and ridiculous. Replace the funky old angle stops with new ones? Remember the nightmare scenario -- no shutting off the building -- certainly not on a Friday afternoon. Dang… it’s time to call Pete the Plumber for some advice. Hope he doesn’t have his head stuck up in the bow of his kayak and he can hear his phone. Turns out he did have his head up in the bow of his kayak, but fortunately for me he was using his cell phone as a flashlight and was able to answer. Before I finished my second sentence, he knew exactly what I was dealing with. He interrupted me, “Those are American Standard angle stops. They’re 7/16” coarse thread and not ½”. They used to sell adapters for those if you can still find them.” Needless to say, “Big Box” didn’t have any such adapters. Neither did the last few remaining neighborhood hardware stores not already pushed out of business by “Aces” or “Big Box” and more recently “Amazonian”. Quite desperate now, I was on my phone Googling anybody that might sell plumbing parts. Shockingly, I discovered a previously unknown “WB Plumbing Supply” located just 10 short blocks away from the job…A quick phone call and finally the words I wanted to hear, “Yeah, we got ‘em. We’ll be open for another half hour. We’ll leave two up at the counter for you”. “20 minutes” had now turned into nearly 4 hours, but I finally had that new faucet connected and just in time for the “crawling” Friday evening commute. If only I’d known about those old American Standard angle stops and their unusual thread size, or realized that small, family-owned plumbing supply stores still exist in SF’s neighborhoods, I could have started my weekend hours earlier. But it also could have turned out a whole lot worse (an embarrassing retreat, or the nightmare of clearing dozens of clogged faucets throughout the building). This was a useful reminder of the invaluable expertise and knowledge you get from your professional plumber and the dedicated stores that serve them. Without our active support to keep them both in business, stories like mine might not have had such a happy ending... Thank you all for reading my little yarn! As I mentioned before, Pete the Plumber has been crustacean-obsessed lately and is presently spending most of his waking hours doing critical ocean-duty kayak modifications before the crabbing season closes. After some well-deserved “rest” in the brine and with luck, a belly full of hot buttered crab, he will return to his regularly scheduled In The Pipe duties. In the meantime, if you should need to reach ol’ Crab Claw Pete, feel free to send him a message. His “flashlight” receives email… Cheers! Daniel Hemp Bayward Builders Welcome back. Everyone survive the turkeys and cranberries? PtP was moving a little slower in all the snow but happy to share with you again.